Magnesium alloy cutting liquid

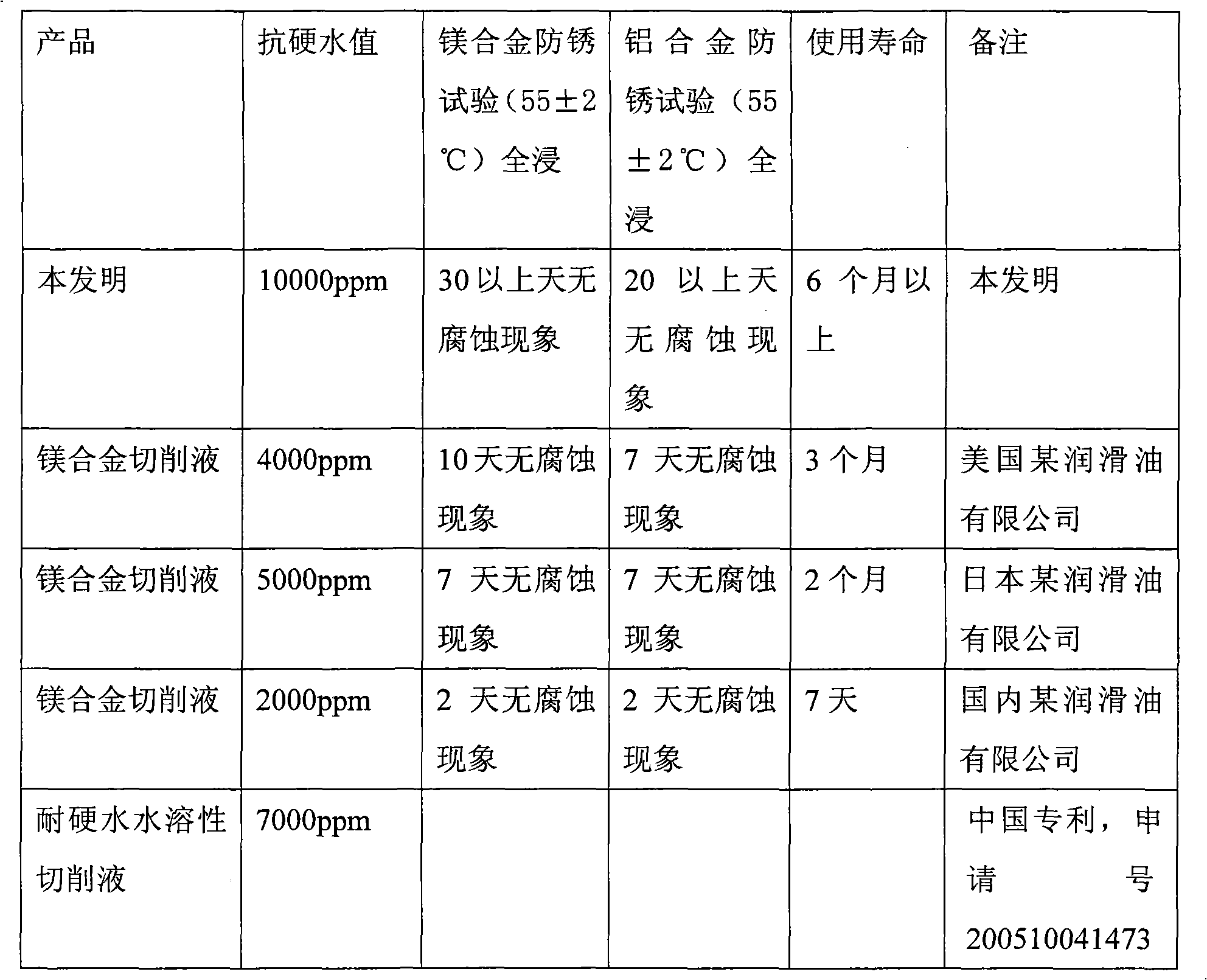

A magnesium alloy and cutting fluid technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve problems affecting industrial applications, discoloration and failure of magnesium alloys, and achieve the effect of inhibiting hydrogen release and excellent rust prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

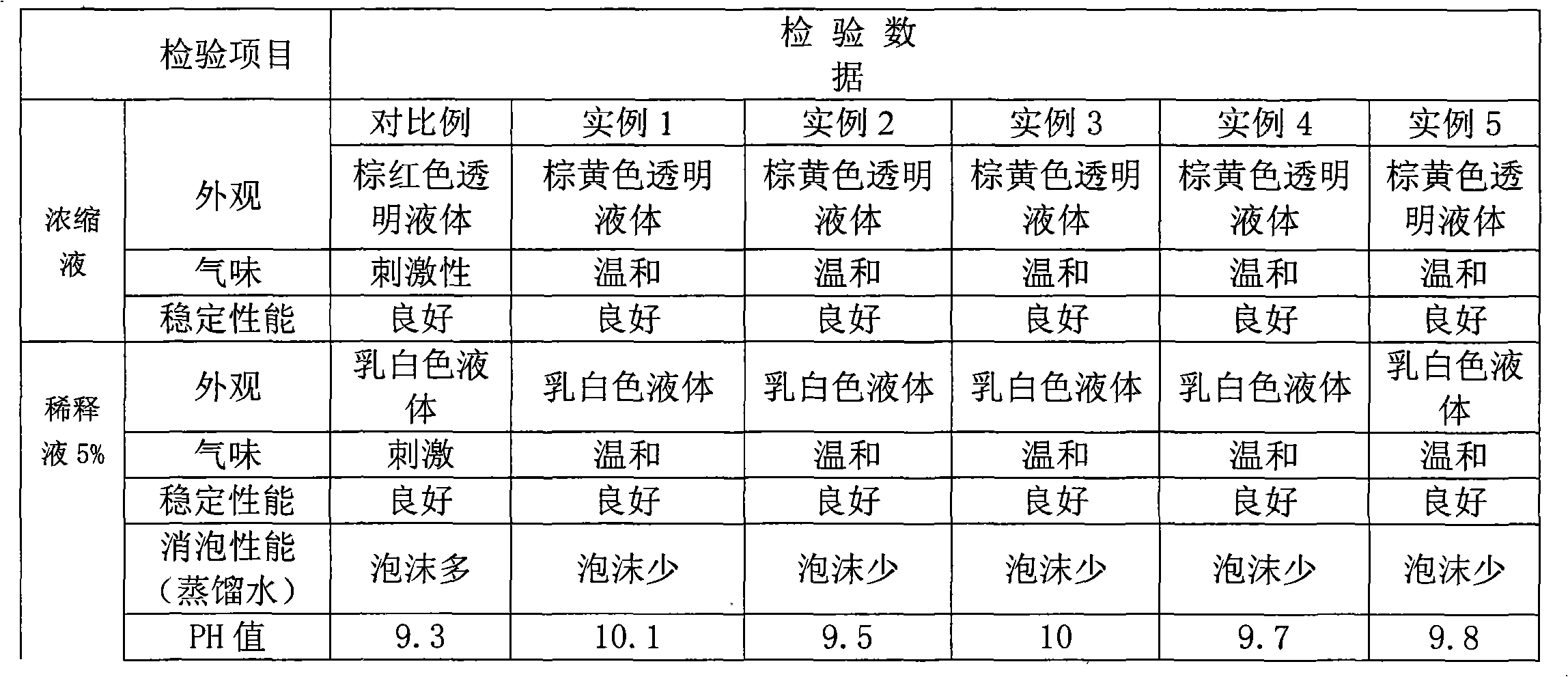

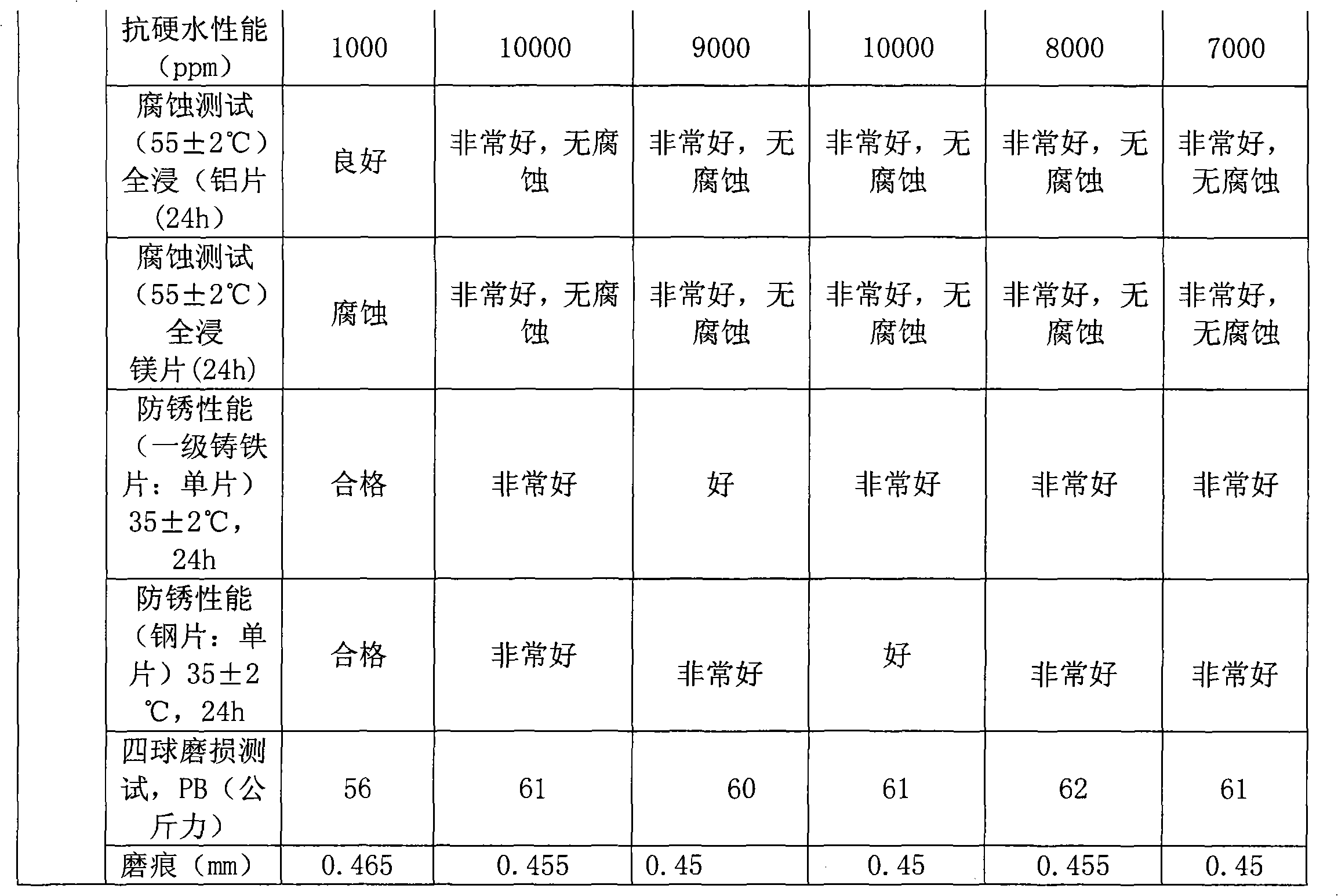

Embodiment 1

[0027] A kind of magnesium alloy cutting fluid; Comprising the raw material of following percentage by weight: naphthenic mineral oil and unsaturated ester 60%, sorbitan oleic acid ester 3%, ricinoleic acid 2%, oleic acid, tall oleic acid Mixed polymeric acid 1%, triethanolamine 1%, monoethanolamine 3%, alkylamine 2%, ether carboxylate ammonium salt 3%, mixture of polymeric acid and dimer acid 7%, tall oil 3%, modified 3% mixture of neutral phosphates and phosphate esters, 3% triazine derivatives and the balance water.

Embodiment 2

[0029] A kind of magnesium alloy cutting fluid; The raw material that comprises following percentage by weight: castor oil unsaturated fatty acid ester 45%, alkylphenol polyoxyethylene ether 8%, dimer acid and ricinoleic acid 2%, ricinoleic acid 3%, Triethanolamine 1%, monoethanolamine 3%, alkylamine 2%, ammonium ether carboxylate 1%, mixture of dimer acid and organic carboxylate 10%, magnesium alloy corrosion inhibitor phosphate 1%, 3, 3 - Methylene (5-methyloxazolidine) 3% and balance water.

Embodiment 3

[0031]A magnesium alloy cutting fluid; comprising the following raw materials in weight percentage: 50% of mixed oil of sunflower oil and cottonseed oil, 3% of fatty alcohol polyoxyethylene ether, 2% of 2-amino-2-methyl-1-propanol , ammonium ether carboxylate 2%, oleic acid, tall oil acid and maleic acid polymerized polymer 30%, triethanolamine 1%, monoethanolamine 4%, mixture of dimer acid and organic carboxylate 15%, 5% mixture of tall oil and 2-amino-2-methyl-1-propanol, 2% mixture of modified phosphoric acid ester and phosphoric acid ester, 4% mixture of triazine derivative and morpholine derivative and balance water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com