Metal grating template making process

A metal grating and metal workpiece technology, which is applied in the field of metal grating stencil production, can solve the problems of low etching pattern precision, poor etching surface finish, slow etching rate, etc. The effect of high graphic precision and large etching depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

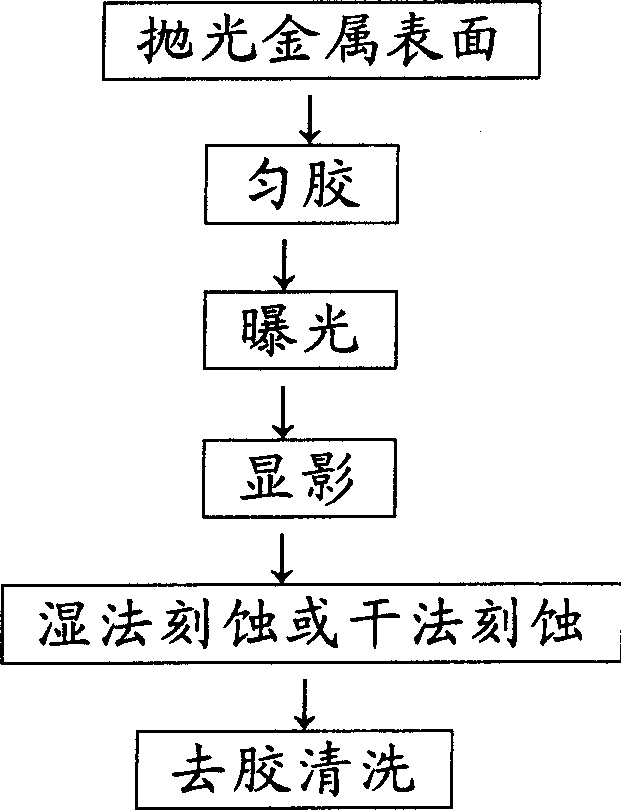

[0014] like figure 1 As shown in the prior art, the method for making a metal grating template is to etch a grating on the metal surface by using a reactive ion etching process of wet etching or dry etching after polishing the metal surface, uniform coating, exposure, and development. Graphics, and then make a metal grating template after degumming.

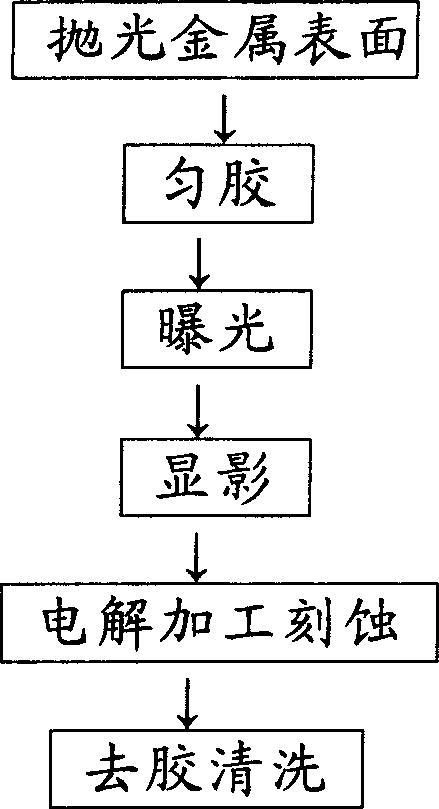

[0015] like figure 2 As shown, the method for making a metal grating stencil by the technology of the present invention is to polish the metal surface, spread the glue, expose, and develop, and then use the electrolytic machining etching process to etch the grating pattern on the metal surface, and then make a metal grating pattern after degumming. Raster template.

[0016] A typical embodiment of the present invention is to make the metal nickel grating stencil of the grating used in the optical disc drive laser head, and its making process is as follows:

[0017] (1) polishing the surface of one side of the grating pattern ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com