Reactive powder concrete for cable trough cover boards of railways

A cable groove cover and active powder technology, applied in the direction of electrical components, etc., can solve the problems of high cost, poor surface finish, and little promotion significance, and achieve the effects of low cost, reduced bone-to-glue ratio, and improved appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The active powder concrete used for the cover plate of railway cable trough is composed of the following raw materials by weight (1 kg per part): 670 parts of P.II42.5 cement, 1120 parts of quartz sand, 162 parts of water, and 320 parts of RPC special admixture , 96 parts of steel fiber, 38 parts of polycarboxylate admixture.

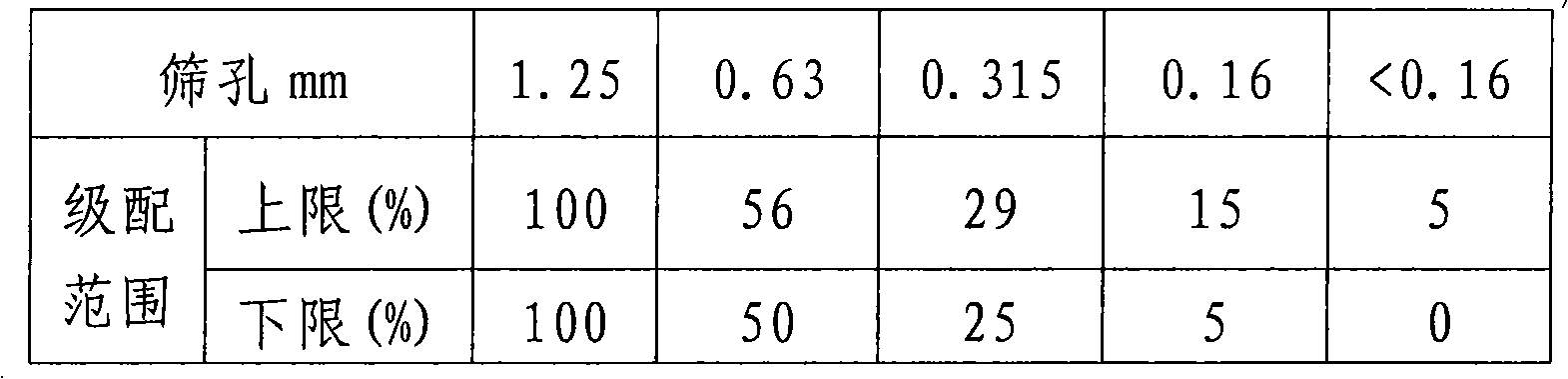

[0023] The quartz sand adopts the quartz sand of Hebei Jinjing Mineral Powder Co., Ltd., and its silicon dioxide content is 99.74%. 0.63-0.315mm) 29%, fine-grained quartz sand (0.315-0.16mm) 15%.

[0024] The cement is Tangshan Jidong Cement Co., Ltd. "Dunshi" brand P.II42.5 cement;

[0025] The RPC admixture adopts the RPC special admixture produced by Beijing Qitian Chemical Co., Ltd.;

[0026] The steel fiber adopts the fine high-strength steel fiber produced by Tianjin Luqiao Baotai Technology Co., Ltd.;

[0027] The polycarboxylate admixture adopts RPC special polycarboxylate high-performance water reducer from Hebei Jinduo Building Mater...

Embodiment 2

[0032] The active powder concrete used for the cover plate of railway cable trough is composed of the following raw materials by weight (1 kg per part): 688 parts of P.II42.5 cement, 1150 parts of quartz sand, 150 parts of water, and 295 parts of RPC special admixture , 85 parts of steel fiber, 35.9 parts of polycarboxylate admixture.

[0033] The quartz sand adopts the quartz sand of Hebei Jinjing Mineral Powder Co., Ltd., and its silicon dioxide content is 99.74%. 0.63 ~ 0.315mm) 34%.

[0034] The cement is Tangshan Jidong Cement Co., Ltd. "Dunshi" brand P.II 42.5 cement;

[0035] The RPC admixture adopts the RPC special admixture produced by Beijing Qitian Chemical Co., Ltd.;

[0036] The steel fiber adopts the fine high-strength steel fiber produced by Tianjin Luqiao Baotai Technology Co., Ltd.;

[0037] The polycarboxylate admixture adopts RPC special polycarboxylate high-performance water reducer from Hebei Jinduo Building Material Technology Development Co., Ltd.

...

Embodiment 3

[0040] The active powder concrete used for the cover plate of the railway cable trough is composed of the following raw materials by weight (1 kg per part): 650 parts of P.II42.5 cement, 1200 parts of quartz sand, 140 parts of water, and 295 parts of RPC special admixture , 85 parts of steel fiber, 33 parts of polycarboxylate admixture.

[0041] The quartz sand adopts the quartz sand of Hebei Jinjing Mineral Powder Co., Ltd., and its silicon dioxide content is 99.74%. 0.63-0.315mm) 29%, fine-grained quartz sand (0.315-0.16mm) 15%.

[0042] The cement is Tangshan Jidong Cement Co., Ltd. "Dunshi" brand P.II42.5 cement;

[0043] The RPC admixture adopts the RPC special admixture produced by Beijing Qitian Chemical Co., Ltd.;

[0044]The steel fiber adopts the fine high-strength steel fiber produced by Beijing Fostar Rail Transit Technology Co., Ltd.;

[0045] The polycarboxylate admixture adopts RPC special polycarboxylate high-performance water reducer from Hebei Jinduo Build...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com