Tungsten-based alloy with grain size having gradient effect and preparation method of tungsten-based alloy

A technology of grain size and tungsten-based alloy, which is applied in the field of tungsten-based alloy and its preparation, can solve the problems of easy peeling, high melting point, and limited improvement methods, and achieve the effect of good surface processing layer, hardness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

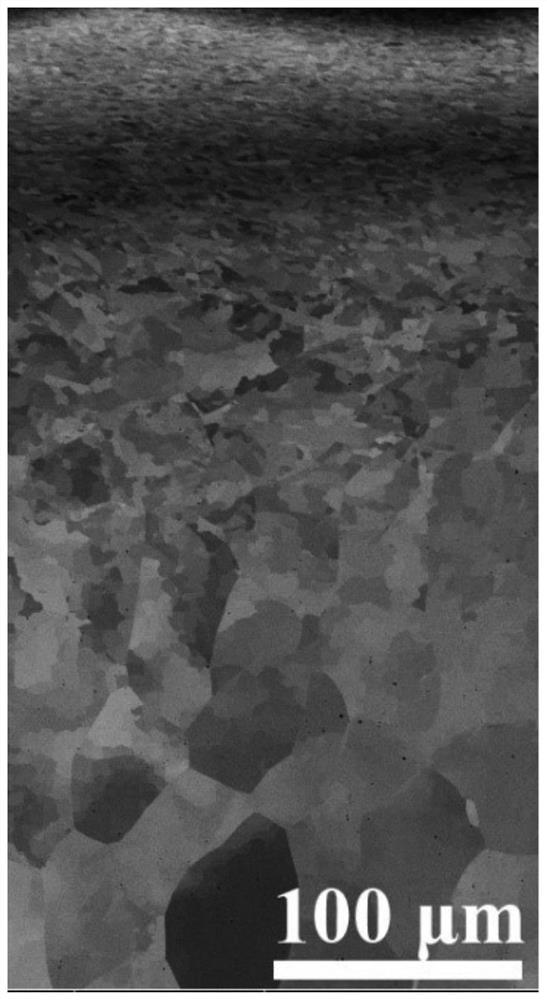

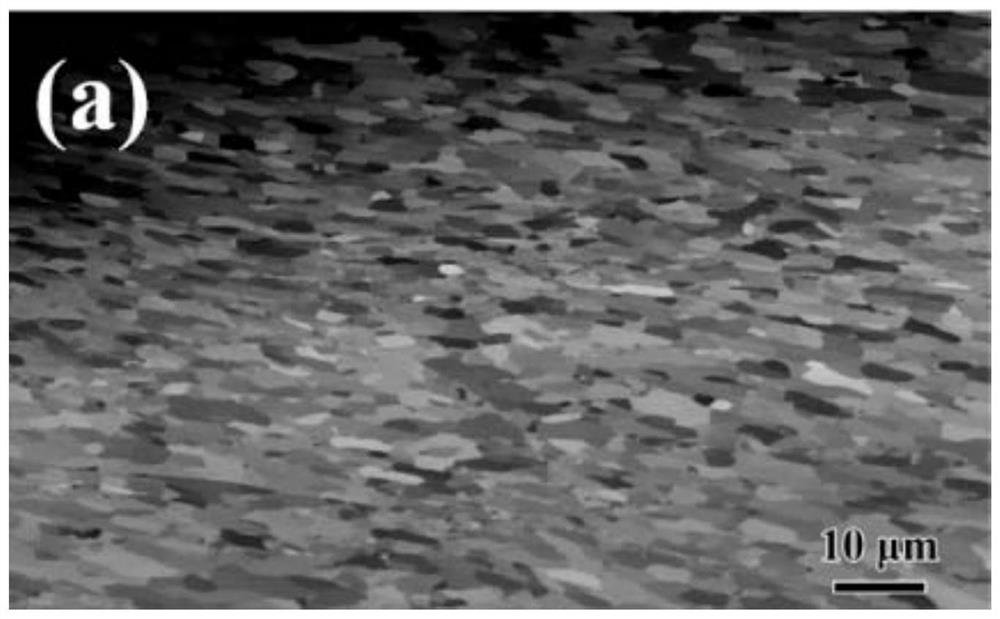

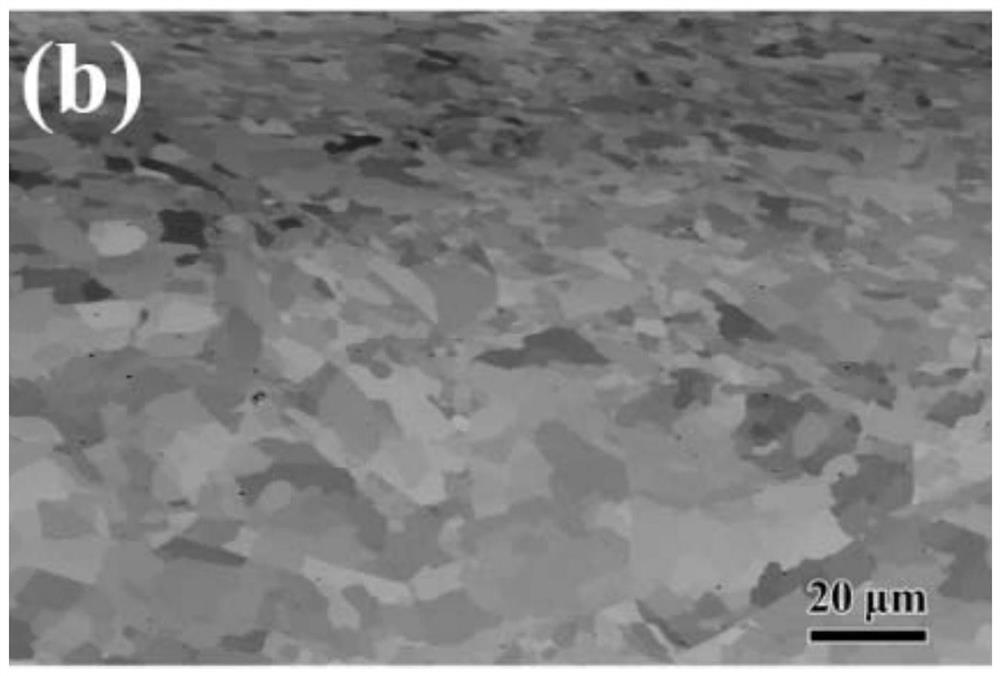

[0039] An embodiment of the tungsten-based alloy having a gradient effect in grain size and its preparation method described in the present invention, the preparation method of the product comprises the following steps:

[0040] (1) Ball mill the high-purity tungsten powder with a particle size of 3-6 μm in an argon atmosphere protection environment, then sinter at 1800 ° C and 200 MPa and use a hot forging machine for thermal deformation treatment, the deformation amount reaches 80 %, the density reaches 99.3%;

[0041] (1-1) Perform annealing experiment on a small part of the substrate after thermal deformation in advance, and confirm that the annealing temperature when the hardness of the substrate decreases by 0.6GPa is 1450°C;

[0042] The first annealing treatment is performed when the temperature of the thermally deformed substrate is lowered to 1450°C, and the time is 2 hours;

[0043] (2) The rod material obtained after the first annealing treatment (the elongation a...

Embodiment 2

[0047] An embodiment of the tungsten-based alloy having a gradient effect in grain size and its preparation method described in the present invention, the preparation method of the product comprises the following steps:

[0048] (1) The high-purity tungsten-potassium powder with a particle size of 3-6 μm is uniformly ball-milled and mixed in an argon atmosphere protection environment, and then sintered at 2000 ° C and 150 MPa and subjected to thermal deformation treatment with a hot forging machine. The amount of deformation reaches 75%, and the density reaches 99.1%;

[0049] (1-1) Perform annealing experiment on a small part of the substrate after thermal deformation in advance, and confirm that the annealing temperature when the hardness of the substrate decreases by 0.4GPa is 1500°C;

[0050] The first annealing treatment is performed when the temperature of the thermally deformed substrate is lowered to 1500 ° C, and the time is 2.5 hours;

[0051] (2) The rod material o...

Embodiment 3

[0053] An embodiment of the tungsten-based alloy having a gradient effect in grain size and its preparation method described in the present invention, the preparation method of the product comprises the following steps:

[0054] (1) The high-purity tungsten-rhenium powder with a particle size of 3-6 μm is uniformly ball-milled and mixed in an argon atmosphere protection environment, and then sintered at 2200 ° C and 80 MPa and subjected to thermal deformation treatment with a hot forging machine. The amount of deformation reaches 78%, and the density reaches 99.3%;

[0055] (1-1) Perform annealing experiment on a small part of the substrate after thermal deformation in advance, and confirm that the annealing temperature when the hardness of the substrate decreases by 0.4GPa is 1520°C;

[0056] The first annealing treatment is performed when the temperature of the thermally deformed substrate is lowered to 1520°C, and the time is 5 hours;

[0057] (2) The rod material obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com