Shifting fork shaft and manufacturing method thereof

A manufacturing method and a technology of shift fork shafts, which are applied in the direction of manufacturing tools, transmission control, grinding machines, etc., can solve problems such as hindering normal use, blackening of the surface of the shifting chute, and stuck shifting steel balls or shafts, etc. Achieve excellent high reliability and stability, excellent surface processing accuracy, and avoid the effect of shifting failure accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (Embodiment 1, shift fork shaft)

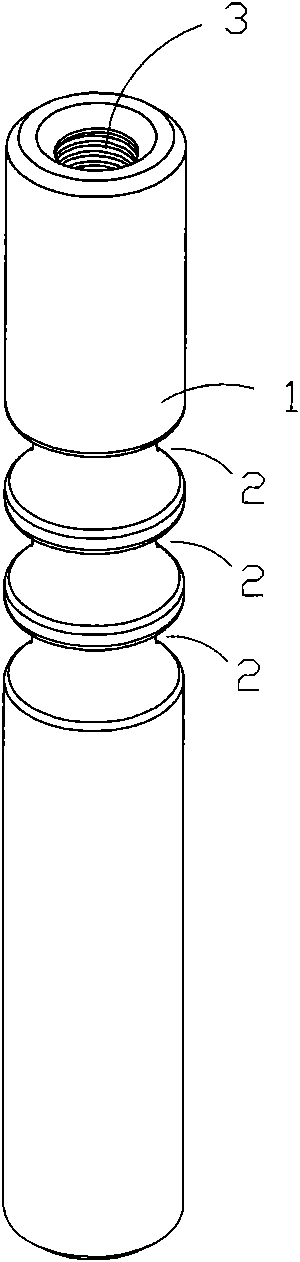

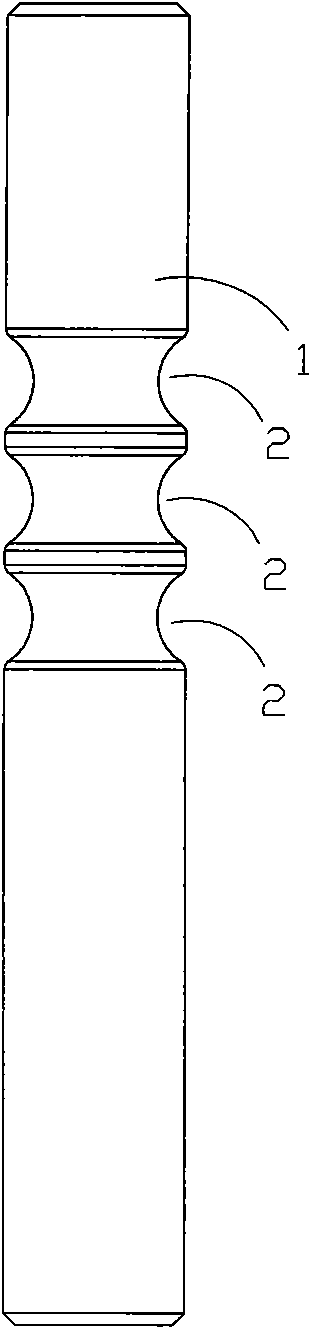

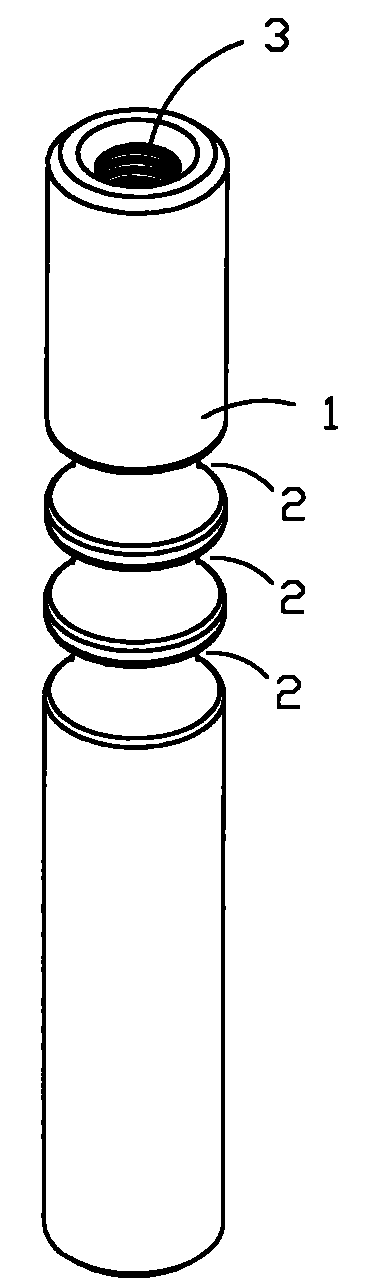

[0022] figure 1 and figure 2 A specific embodiment of the invention is shown in which, figure 1 It is a schematic diagram of a three-dimensional structure of the product of the present invention; figure 2 for figure 1 A front view of the fork shaft shown.

[0023] This embodiment is a shift fork shaft used on agricultural machinery, which is provided with a cylindrical work area 1, and three shift chute 2 are arranged on the work area 1; two axial directions of the shift fork shaft The side end is provided with mounting screw holes 3, and the basic shape of the axial section of each shift chute 2 is arc-shaped, which is semicircular in this embodiment, and the surface of each shift chute 2 is made of nylon. Smooth surface made by grinding with elastic grinding wheel.

[0024] Specifically, the smooth surface of each shift chute 2 is first formed by milling, then quenched, and finally polished with an elastic grinding wheel, so ...

Embodiment 2

[0025] (Example 2, manufacturing method of shift fork shaft)

[0026] This embodiment is a manufacturing method of the shift fork shaft described in Embodiment 1, comprising the following steps:

[0027] ① Select the steel column blank, process the mounting screw holes 3 on both sides of the blank in the axial direction, and mill out a predetermined number of shift chute 2 at its predetermined position;

[0028] ② Perform power frequency quenching treatment on the blank of the milled shift chute 2 to increase the hardness of the shift chute 2;

[0029] ③ Grinding the quenched blank, specifically, using an elastic grinding wheel to grind the shift chute 2, after the surface of the shift chute 2 changes from rough and black to smooth and reflective, it can be used as a finished shift fork shaft; The elastic grinding wheel can be selected from fiber grinding wheel, cloth wheel, or wool wheel, and is further preferably a nylon fiber grinding wheel; in this step, stop grinding whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com