Carbon/carbon composite microsphere material, production method and lithium ion battery

A technology of lithium-ion batteries and production methods, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problems of poor sphericity of materials, complicated preparation process, and harsh process conditions, etc. Achieve the effect of enhancing the compression resistance, reducing the specific surface area and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Mix 5 grams of crushed petroleum coke, 10 grams of gas black, 5 grams of glucose and 150 grams of water, and stir at 50°C for 4 hours to prepare a slurry. The slurry is dried and granulated by a spray dryer, the spray drying inlet temperature is 230°C, and the outlet temperature is 70°C; after drying, initial carbon / carbon composite microspheres can be obtained. Then, the obtained material was heat-treated in a fixed bed at 900° C. for 2 h under the protection of an argon atmosphere to obtain a carbon / carbon composite microsphere material.

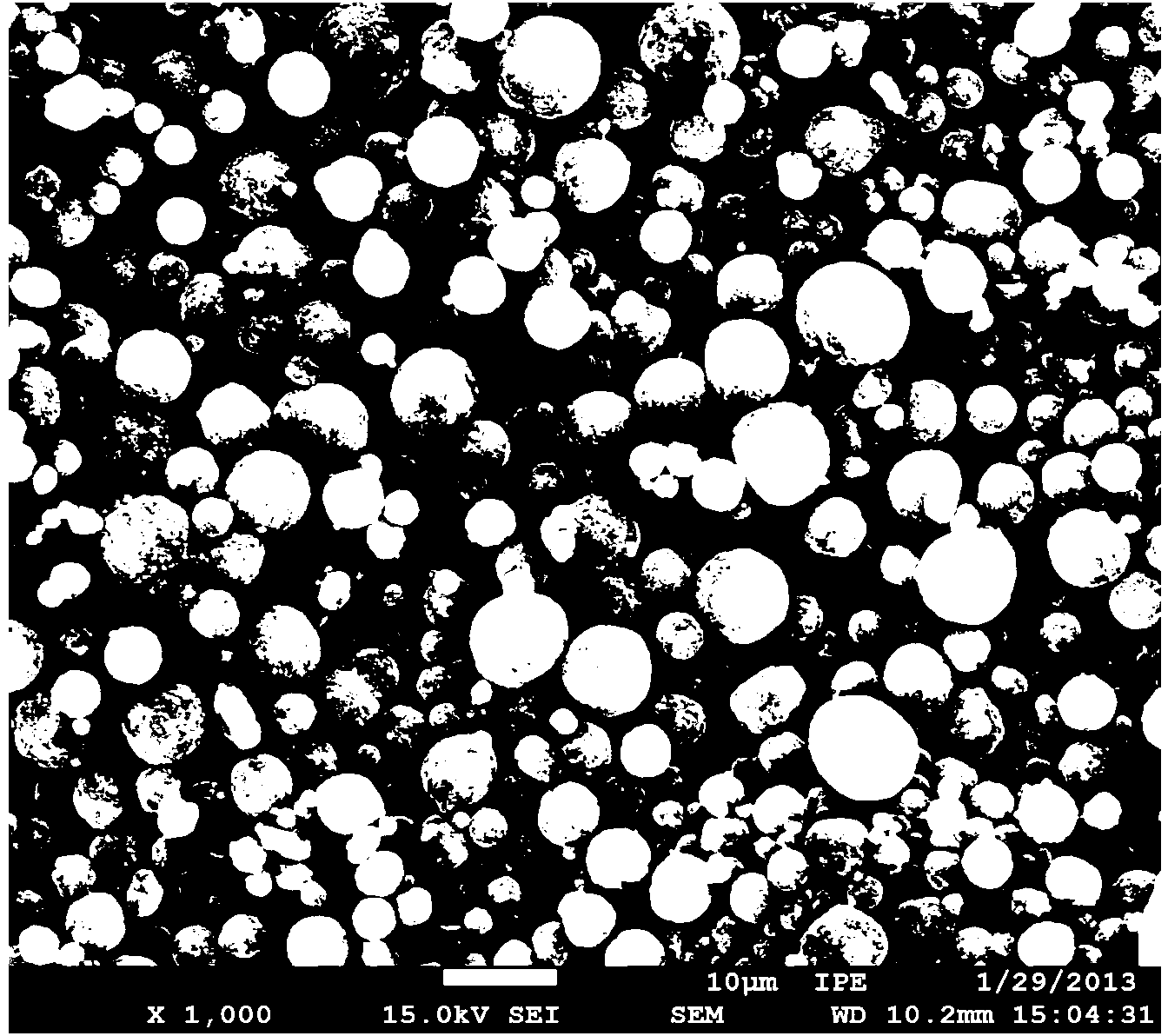

[0061] The carbon / carbon composite microsphere material prepared above was observed with a JSM-7001F field emission scanning electron microscope produced by JEOL Oxford Instruments.

[0062] figure 1 It is the SEM image of the carbon / carbon composite microsphere material obtained in Example 1. The material has a high degree of sphericity.

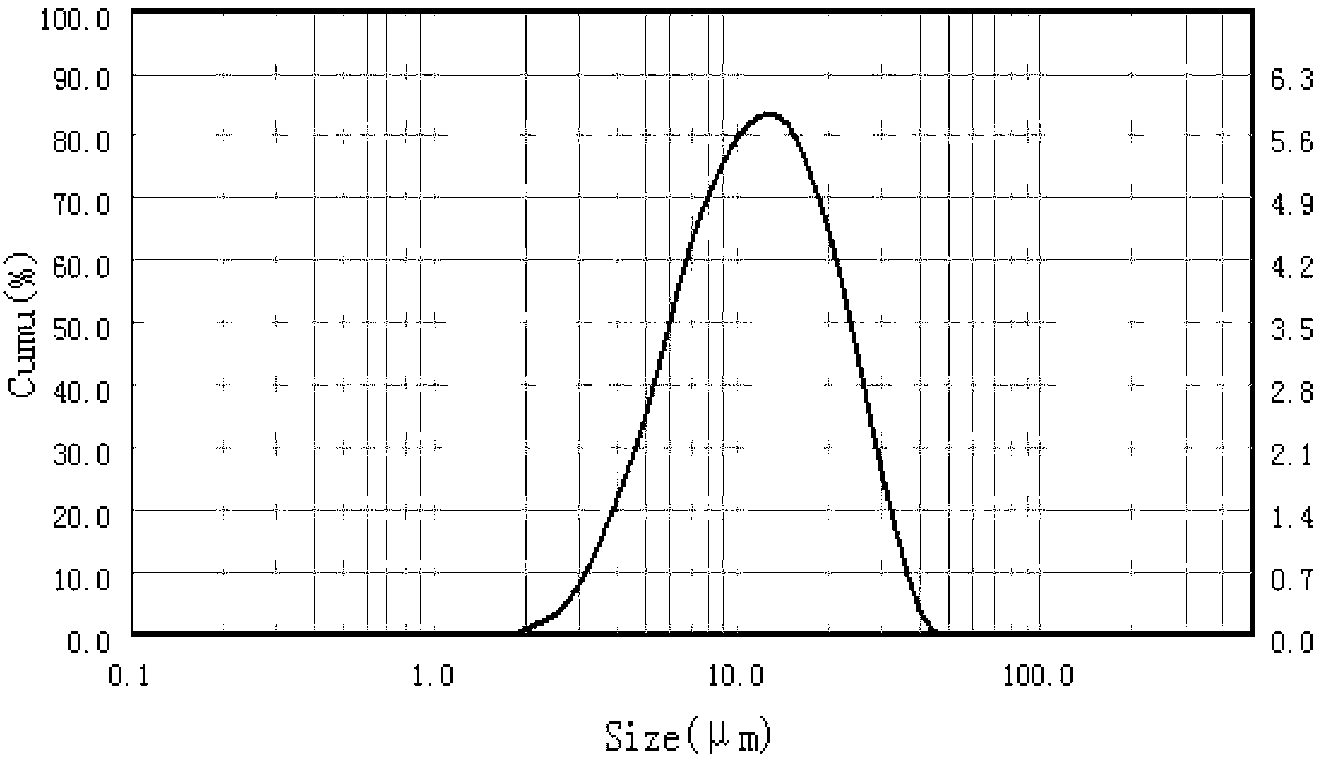

[0063] The carbon / carbon composite microspheres prepared above were analyzed for particle ...

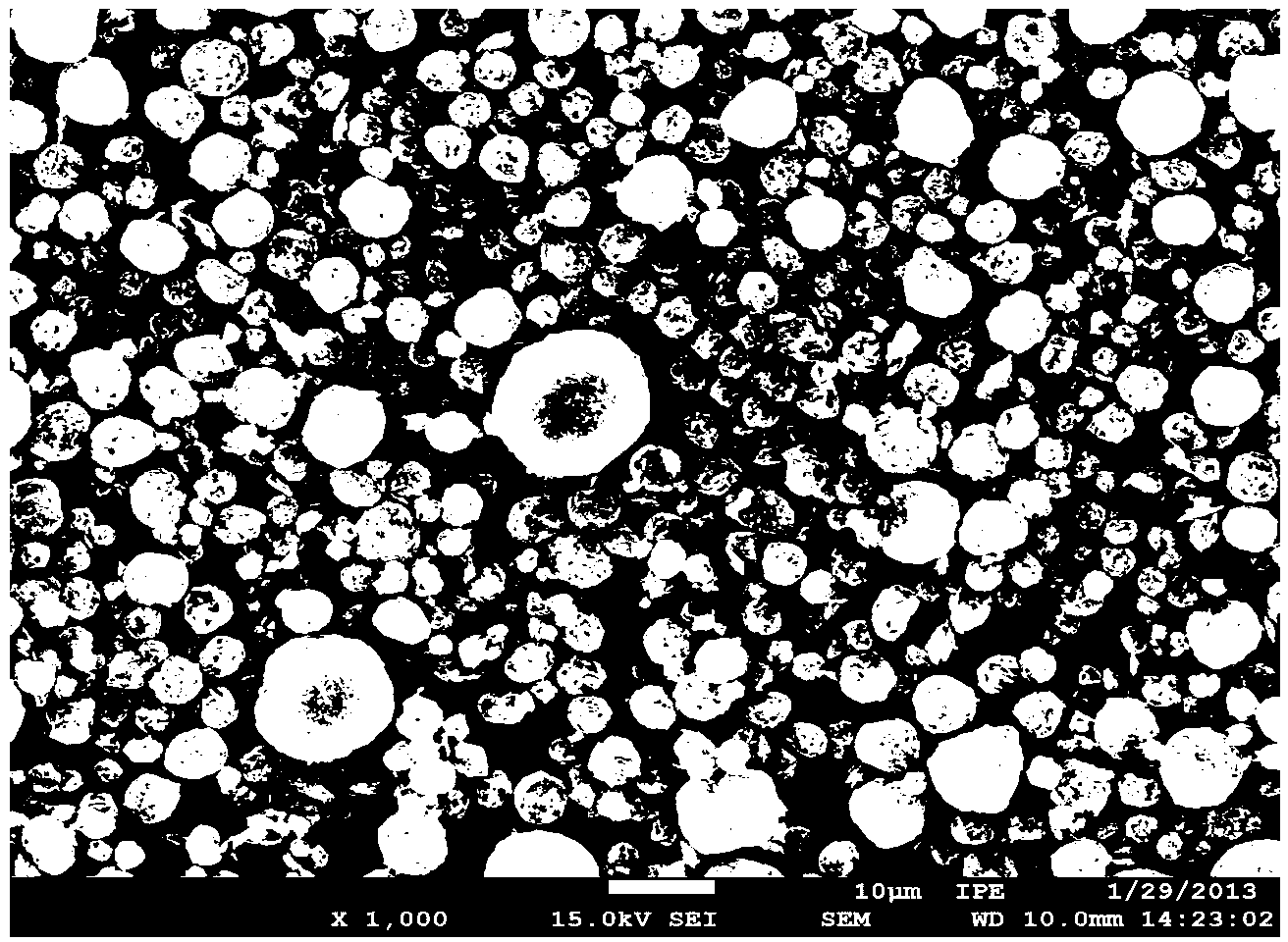

Embodiment 2

[0067] Mix 7 grams of crushed oil-based needle coke, 3 grams of gas black, 5 grams of wheat starch and 120 grams of water, and stir at 40°C for 2 hours to prepare a slurry. The slurry is dried and granulated by a spray dryer, the spray drying inlet temperature is 230°C, and the outlet temperature is 150°C; after drying, initial carbon / carbon composite microspheres can be obtained. Then, the obtained material was heat-treated in a fluidized bed at 1400° C. for 5 h under the protection of a nitrogen atmosphere to obtain a carbon / carbon composite microsphere material. After particle size analysis, the particle size of carbon / carbon composite microspheres is between 2-60 μm; the electrochemical performance test results are shown in Table 1.

Embodiment 3

[0069]Mix 15 grams of crushed coal-based needle coke, 15 grams of cellulose, 10 grams of furnace black, 5 grams of channel black and 300 grams of water, and stir at 30°C for 1.5 hours to prepare a slurry. The slurry is dried and granulated by a spray dryer, the spray drying inlet temperature is 200°C, and the outlet temperature is 100°C; after drying, initial carbon / carbon composite microspheres can be obtained. Then, the obtained material was heat-treated in a stirred bed at 800° C. for 3 h under the protection of a nitrogen atmosphere to obtain a carbon / carbon composite microsphere material. After particle size analysis, the particle size of carbon / carbon composite microspheres is between 10 and 80 μm; the electrochemical performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com