Preparation method for zirconium-based amorphous alloy as well as powder and large-sized block of zirconium-based amorphous alloy

A technology of zirconium-based amorphous alloy and amorphous alloy, which is applied in the field of amorphous alloys, can solve problems such as the limitation of amorphous forming ability, and achieve the effect of large width, high amorphous forming ability and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Example Large size block Zr 61 Cu 15 Ni 12.5 Al 10 Y 1.5 Preparation of Amorphous Alloys

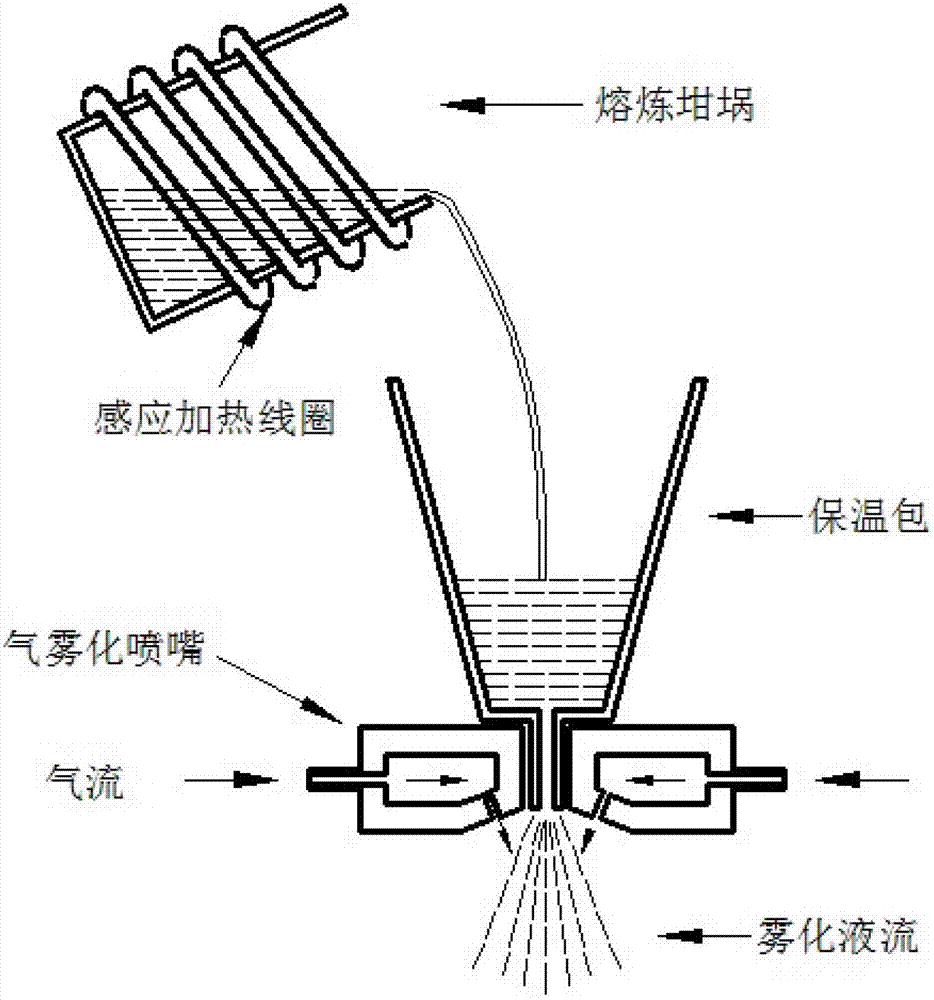

[0028] 1. Preparation of amorphous alloy powder by gas atomization method

[0029] (1) Prepare raw materials according to the element mass ratio of the amorphous alloy to be prepared, and place them in the melting crucible of the gas atomization powder making equipment;

[0030] (2) Vacuumize the gas atomization powder making equipment to 10 -3 Pa, and then rush into argon as a protective gas for protection;

[0031] (3) Melting the raw materials by induction heating until the composition of the alloy solution is uniform;

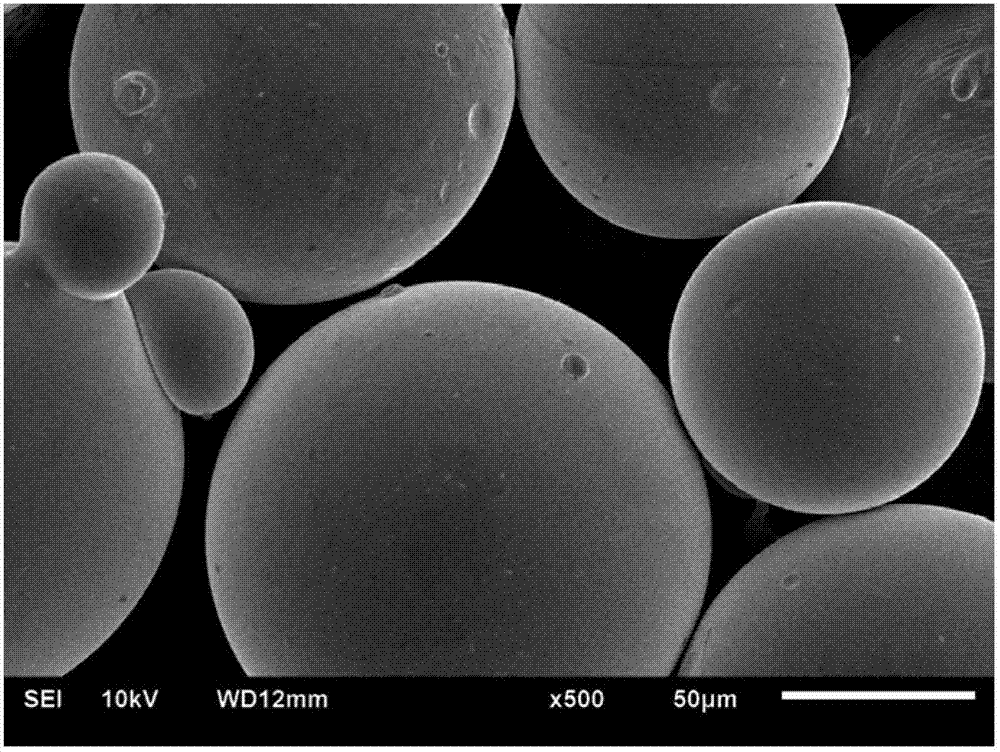

[0032] (4) Pour the smelted alloy solution into the heat preservation bag that has been heated to 1000°C. The solution is atomized into alloy droplets through the nozzle under the action of argon gas not greater than 5MPa, and cooled into powder.

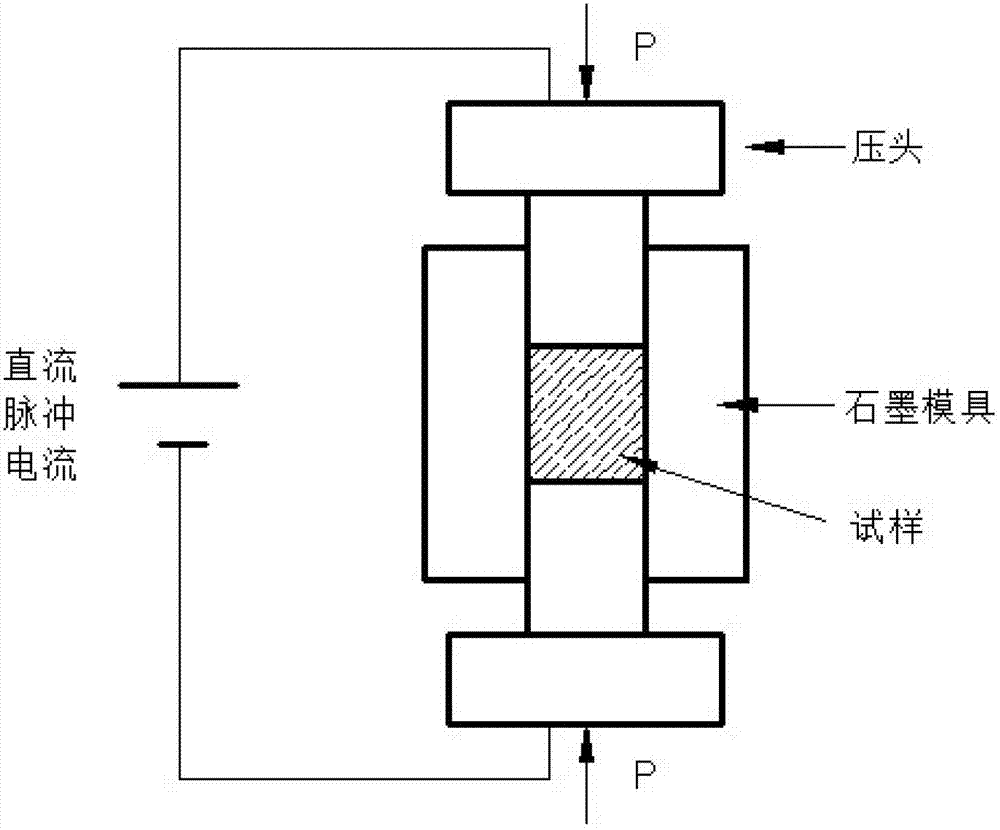

[0033] 2. Preparation of bulk amorphous alloy by spark plasma sintering

[0034] (1) The obtained powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com