Method for enhancing laser energy absorption efficiency of metal powder material

A metal powder and laser energy technology, applied in the field of three-dimensional manufacturing, can solve problems such as difficult to use metal powder materials, achieve high sphericity, enhance laser energy absorption efficiency, improve laser processing efficiency and the effect of mechanical properties of molded parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

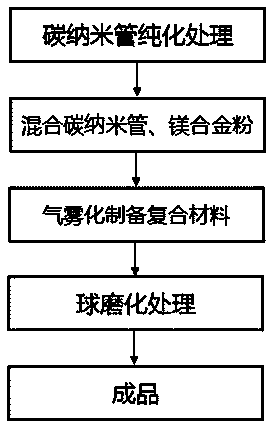

[0025] The method for enhancing the laser energy absorption efficiency of the metal powder material in this embodiment is as follows: figure 1 shown, including the following steps:

[0026] 1) Select 99.5 parts of magnesium alloy powder and 0.5 part of carbon nanotube powder;

[0027] The particle size of the magnesium alloy powder selected in this step is 25 μm, the outer diameter of the carbon nanotube tube wall is 20-30 nm, the length is 20-30 μm, and the purity is >99.9%. ;

[0028] 2) Add the carbon nanotubes selected in step 1) into concentrated H 2 S0 4 / HNO 3 In mixed acid (volume ratio 3:1), purify for 30 minutes, then pickle the carbon material and wash it with deionized water for 2 to 3 times;

[0029] 3) Add the purified carbon nanotube powder in step 2) into the ethanol solution for ultrasonic treatment for 60 minutes to remove impurities such as metallic iron in the carbon nanotube powder, and then add the magnesium alloy powder selected in step 1) into the ...

Embodiment 2

[0034] Embodiment 2: The method for enhancing the laser energy absorption efficiency of metal powder materials in this embodiment includes the following steps:

[0035] 1) Select 99 parts of aluminum alloy powder and 1 part of graphene powder;

[0036] The aluminum alloy powder selected in this step has a particle size of 35 μm, a graphene sheet thickness of 1 to 50 nm, and a sheet width of 0.1 to 1 μm;

[0037] 2) Add the graphene powder selected in step 1) into concentrated H 2 S0 4 / HNO 3 In mixed acid (volume ratio 3: 1), purify for 30 minutes, then pickle the graphene powder and wash it with deionized water for 2 to 3 times;

[0038] 3) Add the purified graphene powder in step 2) into the ethanol solution for ultrasonic treatment for 60 minutes to remove impurities therein, then add the aluminum alloy powder selected in step 1) into the ethanol solution for magnetic stirring and mixing (control the mixing time for 4 hours , the magneton speed is 30r·min -1 ), and fin...

Embodiment 3

[0044] The method for enhancing the laser energy absorption efficiency of the metal powder material in this embodiment includes the following steps:

[0045] 1) choose 98 parts of copper powder and 2 parts of graphite powder;

[0046] The particle size of copper powder selected in this step is 50 μm, and the particle size of graphite powder is 100 nm;

[0047] 2) Add the graphite powder selected in step 1) into concentrated H 2 S0 4 / HNO 3 In the mixed acid (volume ratio 3: 1), purify for 30 minutes, then pickle the graphite powder and wash it with deionized water for 2 to 3 times;

[0048] 3) Add the purified graphite powder in step 2) to the ethanol solution for ultrasonic treatment for 60 minutes to remove impurities therein, then add the copper powder selected in step 1) to the ethanol solution for magnetic stirring and powder mixing (control the powder mixing time for 4 hours, magnetic The sub speed is 30r·min -1 ), and finally dry the powder obtained by magnetic sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com