Metal powder for 3D printer and preparing method thereof

一种3D打印机、金属粉末的技术,应用在金属加工设备、金属材料涂层工艺、附加制造等方向,能够解决金属粉末分散性变差、限制金属粉末应用、金属粉末输送困难等问题,达到球形度高、氧含量低、成分均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

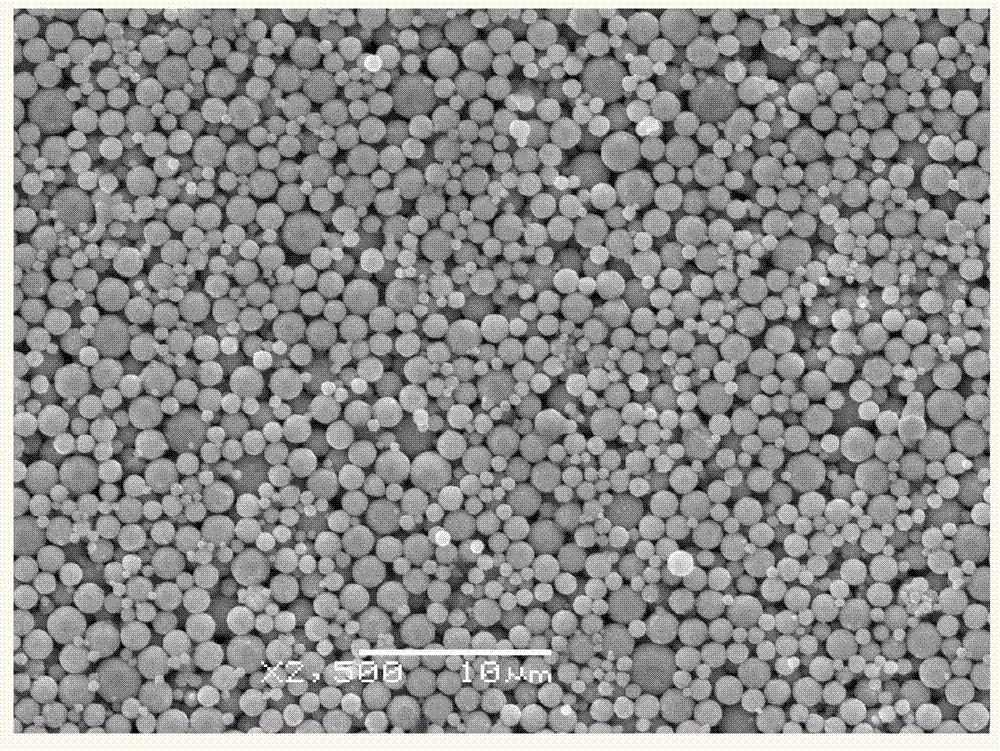

[0035] The physical vapor deposition method is used: the copper-based alloy as the raw material is dissolved in the crucible, and the gas (hydrogen, argon, nitrogen, etc.) enters from the intake pipe in the plasma transfer arc torch and is plasmaized by an external power supply. The plasma transfer arc is generated between the plasma transfer arc torches (that is, the lower end of the plasma transfer arc generated by the plasma transfer arc torch is in contact with the metal liquid level in the crucible); the metal is evaporated and vaporized through the plasma transfer arc; the metal vapor Add inert gas or nitrogen at room temperature into the metal vapor at high speed through the cooling pipeline, so that the temperature of the metal vapor drops below 300°C to obtain copper-based alloy powder with an average particle size of 1.0 microns ( image 3) (the above-mentioned physical vapor deposition method is a conventional method in the industry, which will be described in detail...

Embodiment 2

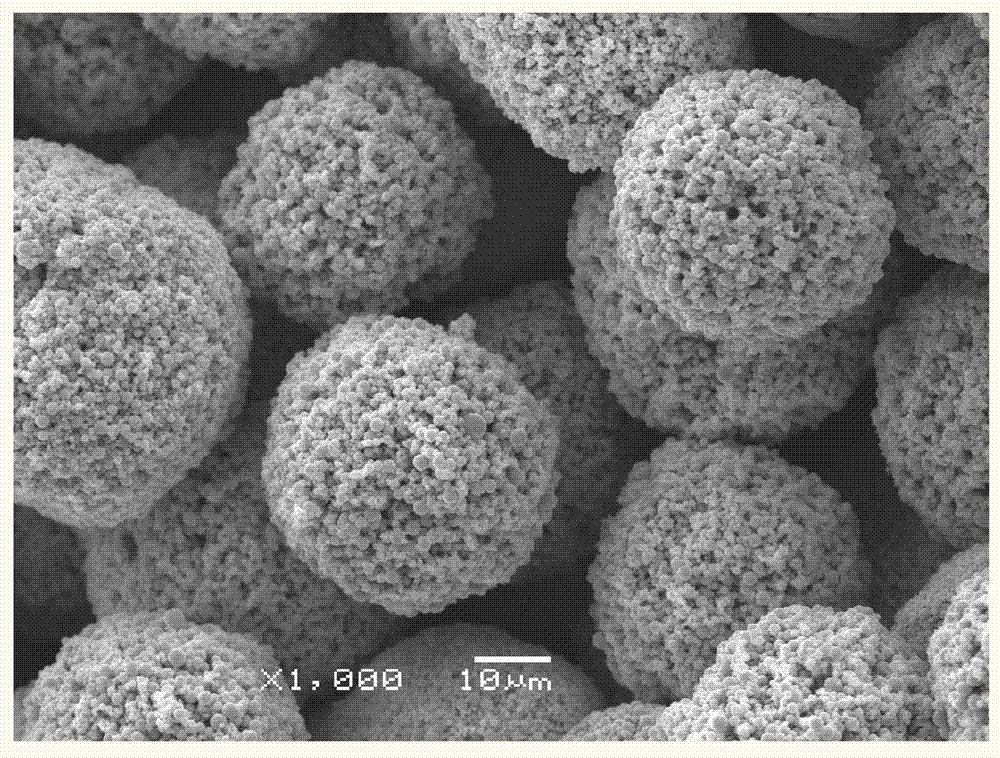

[0037] The average particle diameter that adopts physical vapor deposition method to produce is the titanium base alloy powder of 0.5 micron ( Figure 5 ), and water to form a metal powder slurry with a solid-to-liquid ratio of 2:1. The weight of organic binder (ethyl cellulose) was 1.5% by weight of solids. The metal powder slurry is prepared into spherical metal powder by a centrifugal spray granulator. The speed of the centrifugal spray granulator is controlled at 12000 rpm, the inlet temperature of the dry air is 350°C, the outlet temperature is 120°C, and the flow rate of the dry air is 250Nm 3 / h. The feed rate of the metal powder slurry was 10 kg / h. The dried and granulated metal powder is collected by a cyclone, and the ultra-fine metal powder is collected by a filter bag. The metal powder collected by the cyclone is classified with a vibrating sieve to obtain a metal powder with an average particle diameter of 45 microns ( Image 6 ). The metal powder collected ...

Embodiment 3

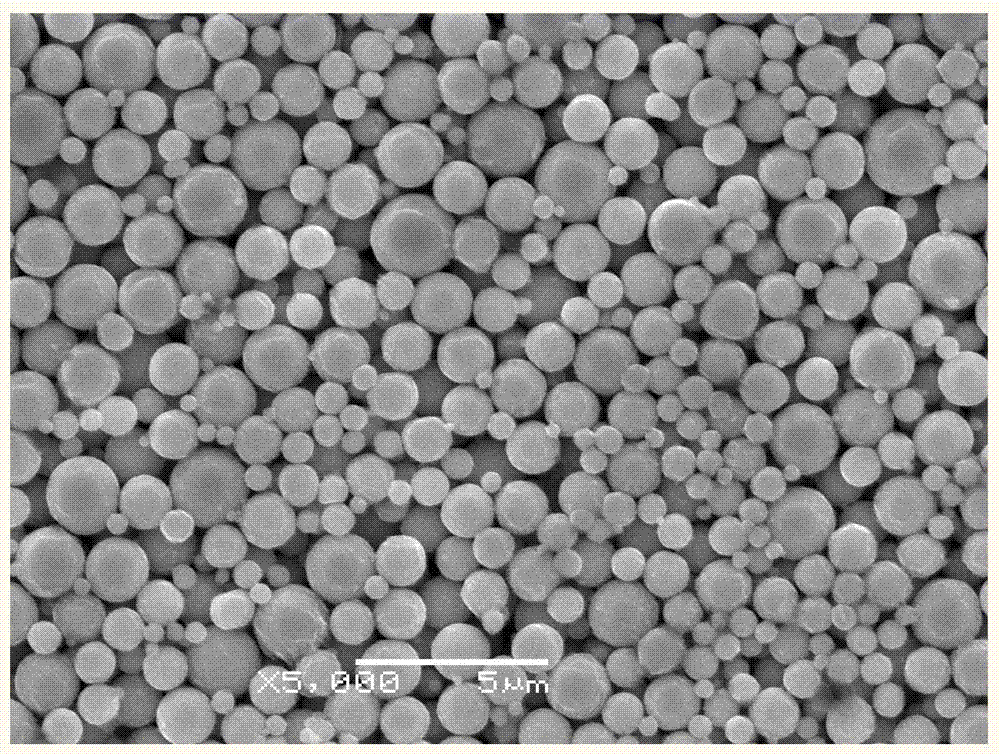

[0039] The average particle diameter that adopts physical vapor deposition method to produce is the nickel base alloy powder of 0.25 micron ( Figure 7 ), and ethanol to form a metal powder slurry with a solid-to-liquid ratio of 1:1. The weight of the organic binder (the model produced by Baoding Jingsu Biotechnology Co., Ltd.: HY-1 metallurgical mineral powder pellet binder) is 1.5% of the solid weight. The metal powder slurry is prepared into spherical metal powder by a centrifugal spray granulator. The speed of the centrifugal spray is controlled at 25000 rpm, the inlet temperature of the dry air is 200°C, the outlet temperature is 90°C, and the flow rate of the dry air is 220Nm 3 / h. The feed rate of the metal powder slurry was 10 kg / h. The dried and granulated metal powder is collected by a cyclone, and the ultra-fine metal powder is collected by a filter bag. The metal powder collected by the cyclone is classified with a vibrating sieve to obtain a metal powder with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com