Multi-component rare earth oxide-doped modified YSZ thermal spraying powder and preparation method thereof

A rare earth oxide, spray powder technology, applied in coating, melting spraying, metal material coating process and other directions, can solve the problem of low solid solution degree of rare earth elements, reduce thermal conductivity, improve powder fluidity, Effect of Gas Thermal Shock Life Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

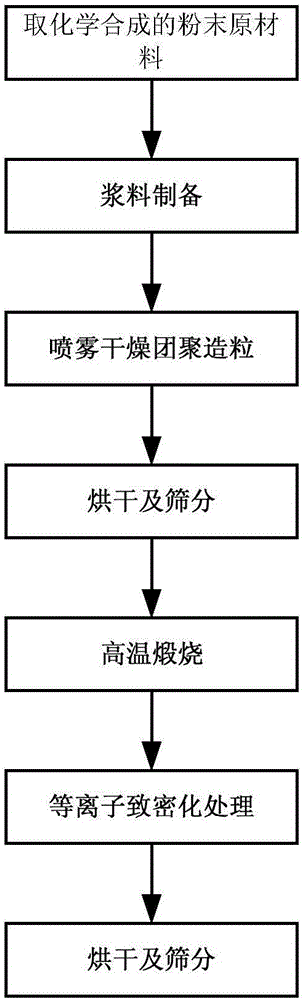

[0037] The present invention proposes a preparation method of multi-element rare earth oxide doped modified YSZ spray powder, comprising:

[0038] Step 1: Take the raw material powder that meets the requirements according to the solid content and the amount of one-time ball milling treatment. Y in the raw material 2 o 3 The content is 5.5~6.5wt%, Gd 2 o 3 The content is 2.5~3wt%, Yb 2 o 3 The content is 2.5~3.5wt%, ZrO 2 -HfO 2 The total amount is 87~89.5wt%, HfO 2 Content is ≤2wt%, HfO 2 ZrO 2 Associated materials;

[0039] Step 2: Slurry preparation: use a stirring ball mill to prepare slurry under the condition of 45-55% solid content, and use 0.1% PVA as a binder to obtain a uniformly dispersed slurry. In order to avoid large aggregate residues, the slurry The material passes through a 20-mesh standard sieve;

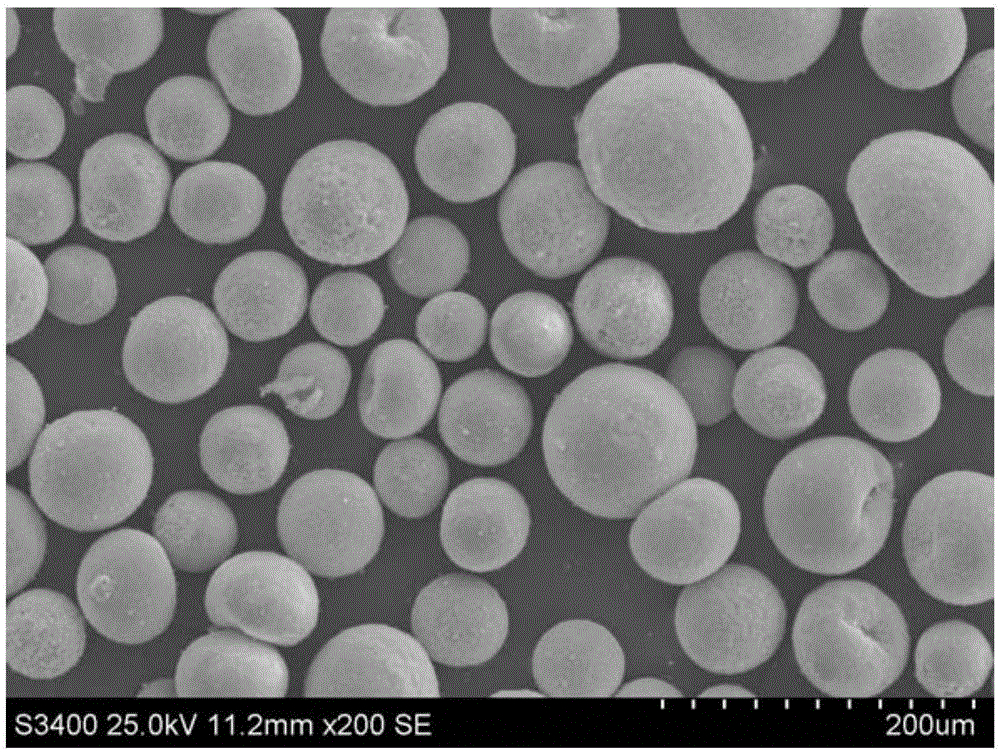

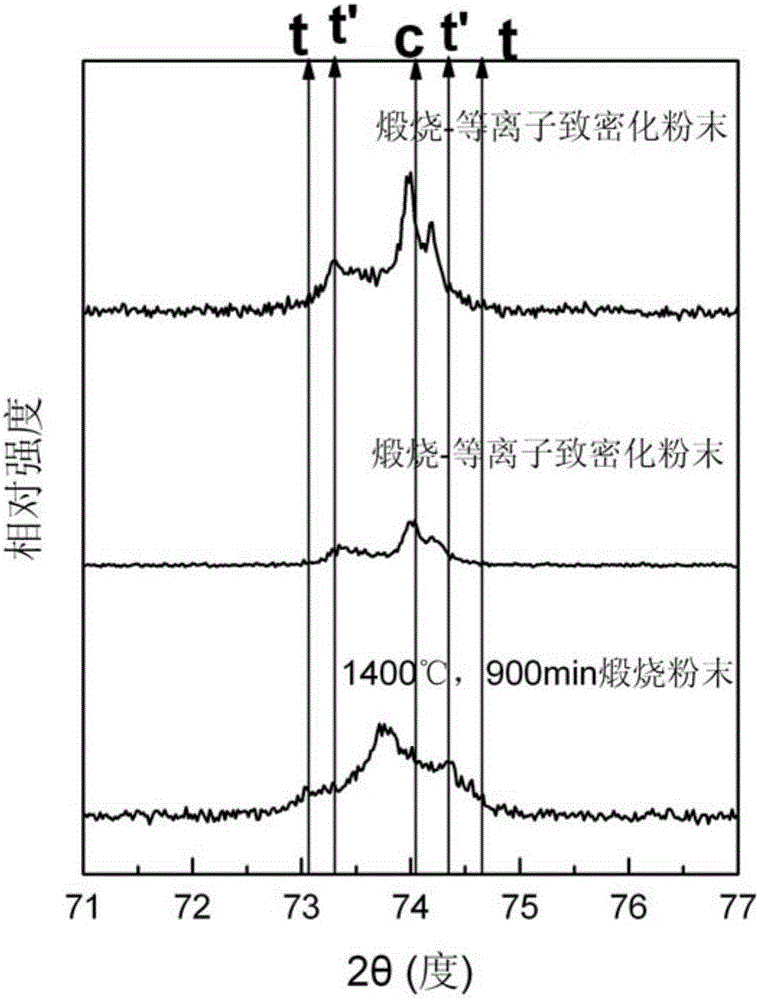

[0040] Step 3: Agglomeration and granulation: Use a high-speed centrifugal spray drying system to perform spray drying and granulation treatment at the s...

Embodiment 1

[0061] The first step: Prepare qualified modified YSZ raw material powder, the average particle size of the original powder is 152nn, Y in the raw material 2 o 3 Content is 6.5%, Gd 2 o 3 Content is 2.5%, Yb 2 o 3 Content is 2.5%, ZrO 2 -HfO 2 Total amount (HfO 2 ZrO 2 Associated material) is 88.41%, HfO 2 The content is 1.78%, and the content of other impurities except rare earth elements is 0.09%. The raw material powder has a mixed structure of tetragonal phase and cubic phase.

[0062] The second step: slurry preparation: mix the raw material powder and pure water, prepare a slurry with a solid content of 55%, and use a stirring ball mill for ball milling, equipped with zirconia balls of mixed sizes, the ball mill is lined with polyurethane, and the ball mill speed 350rpm, ball milling time is 4h, add 0.1% PVA as a binder in the last 10 minutes of ball milling, after ball milling is completed, the slurry is passed through a 20-mesh standard sieve and poured into t...

Embodiment 2

[0070] The first step: Prepare qualified modified YSZ raw material powder, the average particle size of the original powder is 130nn, Y in the raw material 2 o 3 Content is 5.5%, Gd 2 o 3 Content is 3%, Yb 2 o 3 Content is 3.5%, ZrO 2 -HfO 2 Total amount (HfO 2 ZrO 2 Associated material) is 87.91%, HfO 2 The content is 1.52%, the total amount of impurities except the remaining rare earth elements is 0.089%, and the raw material powder has a mixed structure of tetragonal phase and cubic phase. .

[0071] The second step: slurry preparation: mix the raw material powder and pure water, prepare a slurry with a solid content of 45%, and use a stirring ball mill for ball milling, equipped with zirconia balls of mixed sizes, the ball mill is lined with polyurethane, and the ball mill speed is 300rpm, the ball milling time is 2h, no binder is added (the binder content is 0%), after the ball milling is completed, the slurry is poured into the mixing tank after passing through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com