Method for preparing spherical powder material used for three-dimensional printing

A spherical powder, three-dimensional printing technology, applied in the field of preparing spherical powder materials for three-dimensional printing and manufacturing three-dimensional printing consumables, can solve the problems of high production energy consumption, irregular shape, high oxygen content, and achieve precise and controllable process, sphericity The effect of high and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

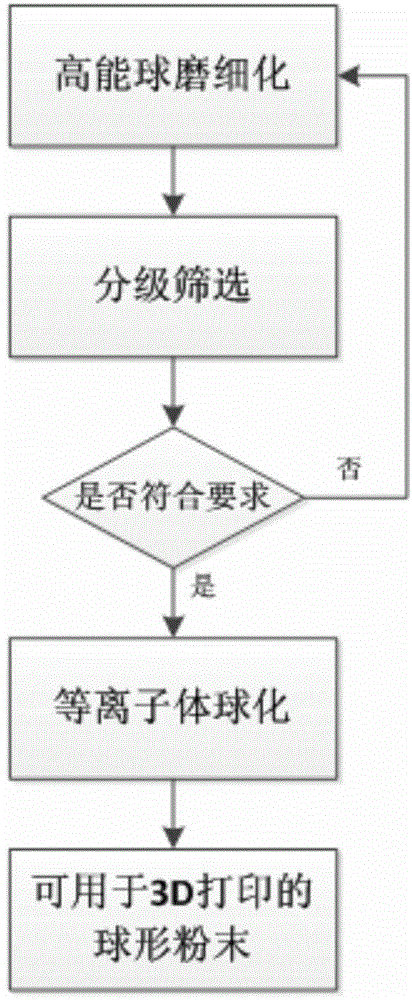

[0022] The method for preparing the spherical powder material for three-dimensional printing in this embodiment is as follows: figure 1 shown, including the following steps:

[0023] 1) Selection of raw materials: The raw materials selected in this embodiment are aluminum alloy powders prepared by purchased powder metallurgy;

[0024] 2) High-energy ball milling: adding the raw materials selected in step 1 into a high-performance ball milling device for ball milling;

[0025] In this embodiment, the ball milling tank is made of agate material, the grinding balls are made of agate balls, the ball-to-material ratio is 2:1, the ball milling time is 2 hours, and the ball milling speed is 1200r / min; in order to control the speed of ball milling and prevent oxidation, this embodiment uses Petroleum ether is used as a process control agent during the ball milling process, and high-purity argon is sealed in the ball milling tank at the same time;

[0026] 3) Screening: screening and...

Embodiment 2

[0030] The method for preparing a spherical powder material for three-dimensional printing in this embodiment includes the following steps:

[0031] 1) Select raw materials: the selected raw materials in this embodiment are stainless steel (stainless steel 316L) powder prepared by powder metallurgy method purchased from outside;

[0032] 2) High-energy ball milling: adding the raw materials selected in step 1 into a high-performance ball milling device for ball milling;

[0033] In this embodiment, the ball milling tank is made of agate material, the grinding balls are made of agate balls, the ball-to-material ratio is 4:1, the ball milling time is 4 hours, and the ball milling speed is 800r / min; in order to control the speed of ball milling and prevent oxidation, this embodiment uses Petroleum ether is used as a process control agent during the ball milling process, and high-purity argon is sealed in the ball milling tank at the same time;

[0034] 3) Screening: screening an...

Embodiment 3

[0038] The method for preparing a spherical powder material for three-dimensional printing in this embodiment includes the following steps:

[0039] 1) Select raw materials: the selected raw materials in this embodiment are titanium alloy (TC4) powder prepared by powder metallurgy method purchased from outside;

[0040] 2) High-energy ball milling: adding the raw materials selected in step 1 into a high-performance ball milling device for ball milling;

[0041] In this embodiment, the ball milling tank is made of WC material, the grinding balls are WC balls, the ball-to-material ratio is 6:1, the ball milling time is 6 hours, and the ball milling speed is 600r / min; in order to control the speed of ball milling and prevent oxidation, this embodiment uses Petroleum ether is used as a process control agent during the ball milling process, and high-purity argon is sealed in the ball milling tank at the same time;

[0042] 3) Screening: screening and grinding the obtained powder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com