Isostatic cool pressing molding die for ceramic tube and molding method

A technology of cold isostatic pressing and ceramic tubes, which is applied in the direction of ceramic molding machines, molds, manufacturing tools, etc., can solve the problem that the tubular ceramic parts cannot be completely isostatic pressed, and achieve the solution of green body density gradient and small sintering deformation , The effect of uniform density of green body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

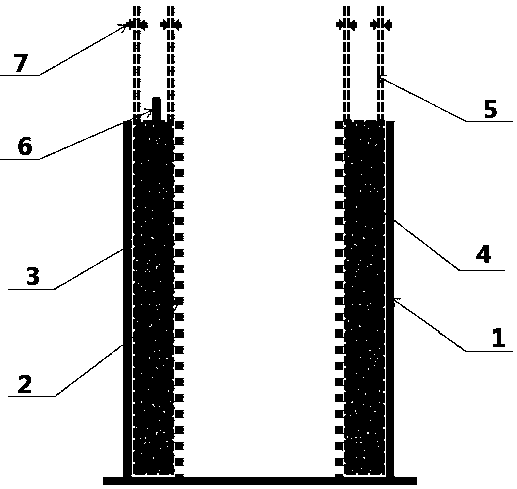

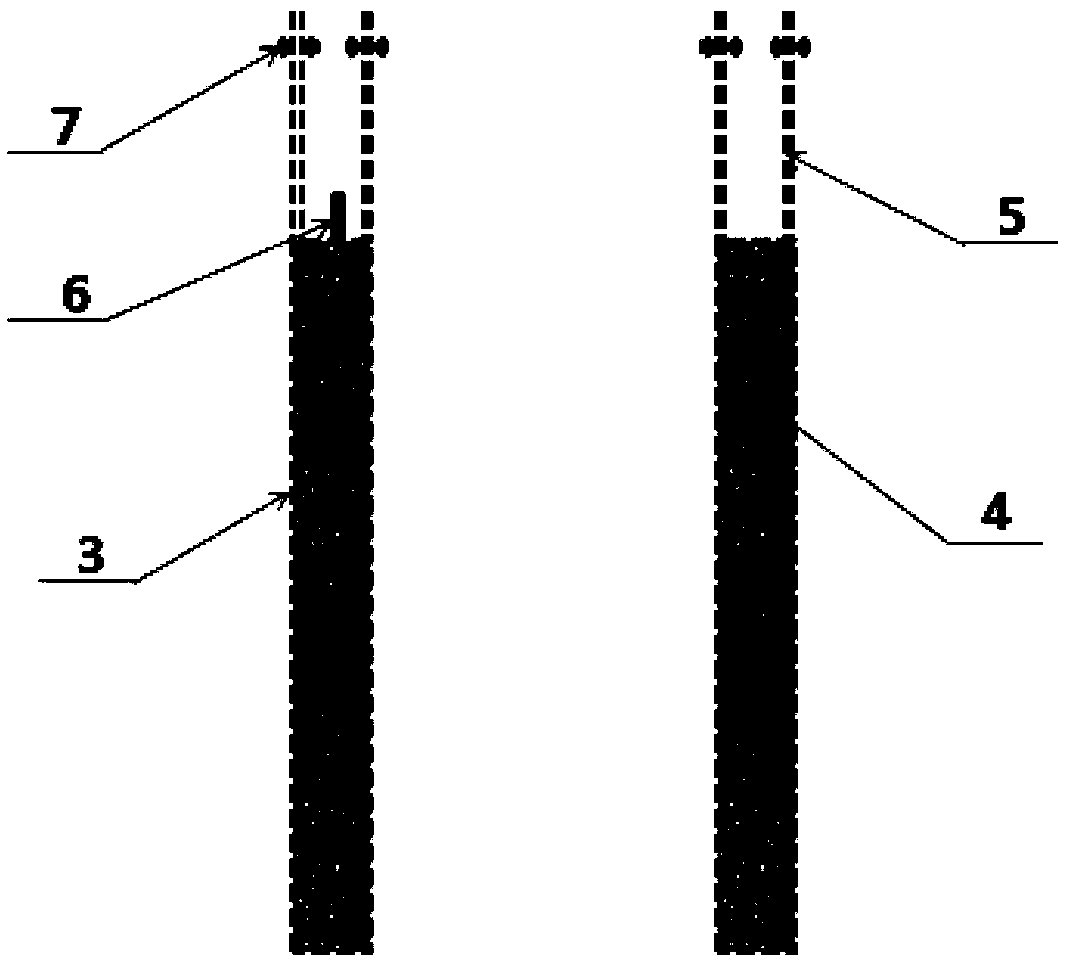

[0048] A solid-phase sintered SiC ceramic tube with an outer diameter of 650 mm, an inner diameter of 615 mm, and a height of 500 mm was prepared, and the average particle size of the powder was 90 μm. According to the sintering shrinkage rate of ceramics and the compression shrinkage rate of loose powder, according to figure 1 Design and make molds. Put the lower mold sleeve made of nitrile rubber into the steel mold, vibrate while feeding, and the vibration frequency is 50Hz. After filling the powder, install the upper mold cover made of nitrile rubber and seal it with a wire rope. Carry out vacuum pumping through the pumping hole for 30 minutes, and close the vacuum valve after the vacuum degree reaches 1 mbar. After holding the pressure for 60 minutes, the vacuum still reached 2mbar. Take out the sealed mold sleeve from the steel mold and put it into an isostatic press for 200MPa isostatic pressure treatment. After pressing, the mold cover is taken out to obtain a cera...

Embodiment 2

[0050] A solid-phase sintered SiC ceramic tube with an outer diameter of 463 mm, an inner diameter of 443 mm, and a height of 500 mm was prepared, and the average particle size of the powder was 50 μm. According to the sintering shrinkage rate of ceramics and the compression shrinkage rate of loose powder, according to figure 1 Design and make molds. Put the lower mold sleeve made of natural rubber into the steel mold, vibrate while feeding, and the vibration frequency is 100Hz. After the powder is filled, install the upper mold cover made of natural rubber and seal it with a rubber ring. Carry out vacuum pumping through the pumping hole for 60 minutes, and close the vacuum valve after the vacuum degree reaches 5 mbar. After holding the pressure for 60 minutes, the vacuum degree still reaches 8mbar. Take out the sealed mold sleeve from the steel mold and put it into an isostatic press for 200MPa isostatic pressure treatment. After pressing, the mold cover is taken out to o...

Embodiment 3

[0052] A liquid-phase sintered SiC ceramic tube with an outer diameter of 1540 mm, an inner diameter of 1500 mm, and a height of 600 mm was prepared, and the average particle size of the powder was 0.6 μm. According to the sintering shrinkage rate of ceramics and the compression shrinkage rate of loose powder, according to figure 1 Design and make molds. Put the lower mold sleeve made of polyurethane rubber into the steel mold, vibrate while feeding, and the vibration frequency is 100Hz. After the powder is filled, install the upper mold cover made of polyurethane rubber and seal it with a rubber ring. Carry out vacuum pumping through the pumping hole for 60 minutes, and close the vacuum valve after the vacuum degree reaches 5 mbar. After holding the pressure for 60 minutes, the vacuum degree still reaches 8mbar. Take out the sealed mold sleeve from the steel mold and put it into an isostatic press for 200MPa isostatic pressure treatment. After pressing, the mold cover is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com