Powder metallurgy aluminum-based material and preparation method thereof

An aluminum-based material and powder metallurgy technology, applied in the field of powder metallurgy, can solve problems such as hindering mass production and sintering deformation, and achieve the effects of avoiding sintering deformation, low cost, and reducing mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

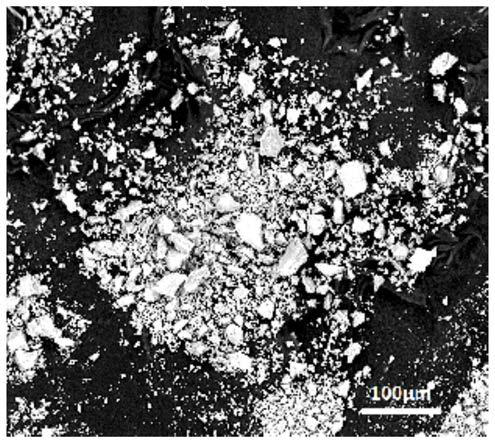

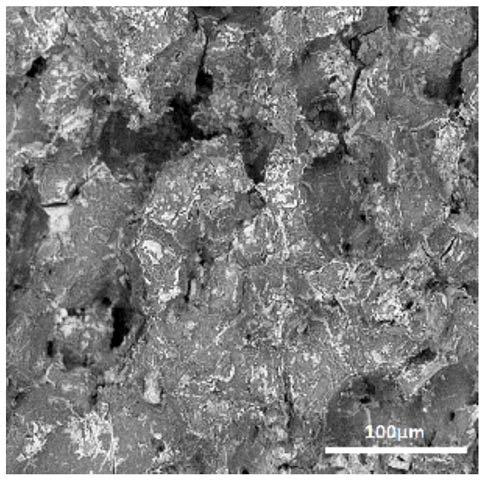

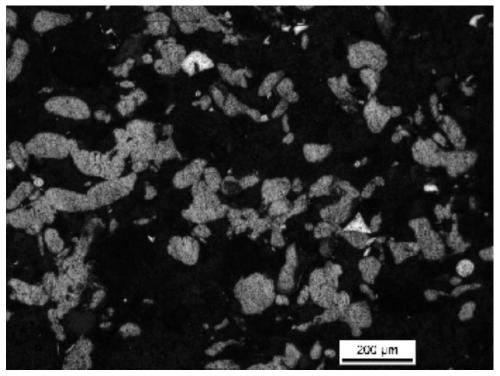

Image

Examples

Embodiment 1

[0030] In this embodiment, taking the pure aluminum matrix as an example, the preparation method of the powder metallurgy aluminum-based material is described, which specifically includes the following steps:

[0031] (1) Powder mixing: the aluminum elemental powder with an average particle size of 60 μm and the zirconium hydride powder with an average particle size of 45 μm are uniformly ground and mixed with a mortar to obtain a raw material powder, wherein the mass fraction of the zirconium hydride powder in the raw material powder is 0.02 %, the balance is aluminum elemental powder. The zirconium hydride powder used in this step may preferably have a purity of 99.9%, wherein the mass ratio of hydrogen element to zirconium element is 2.

[0032] (2) Forming: The powder obtained in step (1) is subjected to compression molding, the pressing pressure is 150 MPa, and the holding time is 15 s.

[0033] (3) Sintering: tube furnace is used for sintering, and the sintering protect...

Embodiment 2

[0036] In this embodiment, taking the 2014 aluminum alloy substrate as an example, the preparation method of the powder metallurgy aluminum-based material is described, which specifically includes the following steps:

[0037] (1) Powder mixing: the 2014 aluminum alloy powder with an average particle size of 78 μm and the zirconium hydride powder with an average particle size of 10 μm are mixed to obtain a raw material powder, and the raw material powder is ball milled on a planetary ball mill with a rotation speed of 170 r / min for 9 hours and mixed evenly. The mass fraction of the zirconium hydride powder in the raw material powder is 8.5%, and the balance is 2014 aluminum alloy powder. The preferred purity of the zirconium hydride powder used in this step is 99.0%, wherein the mass ratio of hydrogen element to zirconium element is 1.5.

[0038] (2) Forming: Utilize a V-shaped mixer to mix into the powder obtained in step (1) and account for 0.5wt% zinc stearate as a lubrican...

Embodiment 3

[0043] In this embodiment, taking the 7039 aluminum alloy substrate as an example, the preparation method of the powder metallurgy aluminum-based material is described, which specifically includes the following steps:

[0044] (1) Powder mixing: the 7039 aluminum alloy powder with an average particle size of 45 μm and the zirconium hydride powder with an average particle size of 16 μm are mixed to obtain a raw material powder, and the raw material powder is ball milled on a planetary ball mill with a rotating speed of 150 r / min for 16 hours and mixed evenly. The mass fraction of the zirconium hydride powder in the raw material powder is 15%, and the balance is 7039 aluminum alloy powder. The zirconium hydride powder used in this step may preferably have a purity of 99%, wherein the mass ratio of hydrogen element to zirconium element is 1.4.

[0045] (2) Forming: use a spiral mixer to mix zinc stearate that accounts for 0.8% of the mass fraction of the raw material powder into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com