Making method of low-deformation toughened silica-based ceramic core

A technology of ceramic core and manufacturing method, which is applied in the field of precision casting to achieve the effects of reducing sintering deformation, lowering sintering temperature and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The manufacturing method of the low-deformation toughened silicon-based ceramic core of the present embodiment is carried out according to the following steps:

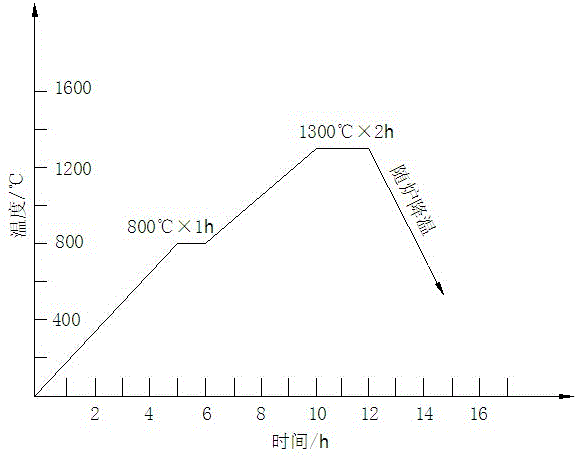

[0019] (1) Weigh the powder according to the weight ratio of magnesia fiber to zirconia 1:40, put the powder into a ball mill and mix it for 0.5h, then put it into a roaster for roasting, the roasting conditions are as follows figure 1 As shown, the temperature is raised to 800°C at a heating rate of 160°C / h, kept at 800°C for 1 hour, then raised to 1300°C at a heating rate of 125°C / h, kept at 1300°C for 2 hours, and then discharged with the furnace to cool to room temperature , put into the grinder after discharging, add the grinding body in a weight ratio of 1:1, after grinding for 1.5h, pass through a 200 mesh sieve, and the powder obtained is used as a prefabricated mineralizer for subsequent use;

[0020] (2) According to weight percentage, 22% of 270-360-mesh quartz glass powder, 55% of 600-800-mesh quart...

Embodiment 2

[0023] The manufacturing method of the low-deformation toughened silicon-based ceramic core of the present embodiment is carried out according to the following steps:

[0024] (1) Weigh the powder according to the weight ratio of magnesia fiber to zirconia 1:45, put the powder into the ball mill and mix it for 0.5h, then put it into the roaster for roasting, as figure 1 As shown, the calcination condition is to heat up to 800°C at a heating rate of 160°C / h, hold at 800°C for 1 hour, then raise the temperature to 1300°C at a heating rate of 125°C / h, hold at 1300°C for 2 hours, and then cool to room temperature with the furnace Discharging, after discharging, put it into the grinder, add grinding body at a weight ratio of 1:1, after grinding for 3 hours, pass through a 200-mesh sieve, and the obtained powder is used as a prefabricated mineralizer for subsequent use;

[0025] (2) According to weight percentage, 33% of 270-mesh-360-mesh quartz glass powder, 50% of 600-mesh-800-mes...

Embodiment 3

[0028] The manufacturing method of the low-deformation toughened silicon-based ceramic core of the present embodiment is carried out according to the following steps:

[0029] (1) Weigh the powder according to the weight ratio of magnesia fiber to zirconia 1:42, put the powder into a ball mill and mix it for 0.5h, then put it into a roaster for roasting, as figure 1 As shown, the calcination condition is to heat up to 800°C at a heating rate of 160°C / h, hold at 800°C for 1 hour, then raise the temperature to 1300°C at a heating rate of 125°C / h, hold at 1300°C for 2 hours, and then cool to room temperature with the furnace Discharging, after discharging, put it into the grinder, add grinding body at a weight ratio of 1:1, after grinding for 2 hours, pass through a 200-mesh sieve, and the obtained powder is used as a prefabricated mineralizer for subsequent use;

[0030] (2) According to weight percentage, 45% of 270-360-mesh quartz glass powder, 40% of 600-800-mesh quartz glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com