Method for preparing porous tantalum medical implant material

An implant material, porous tantalum technology, applied in medical science, prosthesis, etc., can solve problems such as unsatisfactory needs, achieve the effect of ensuring biocompatibility and biosafety, simple process, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

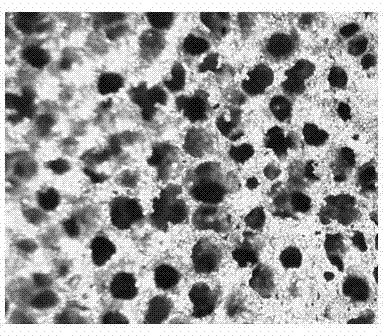

Image

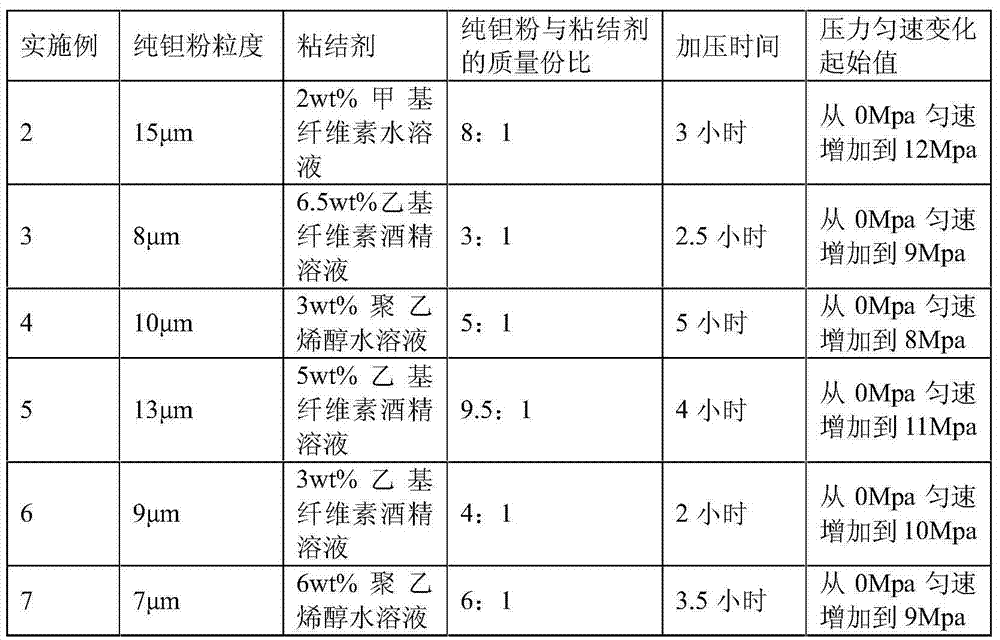

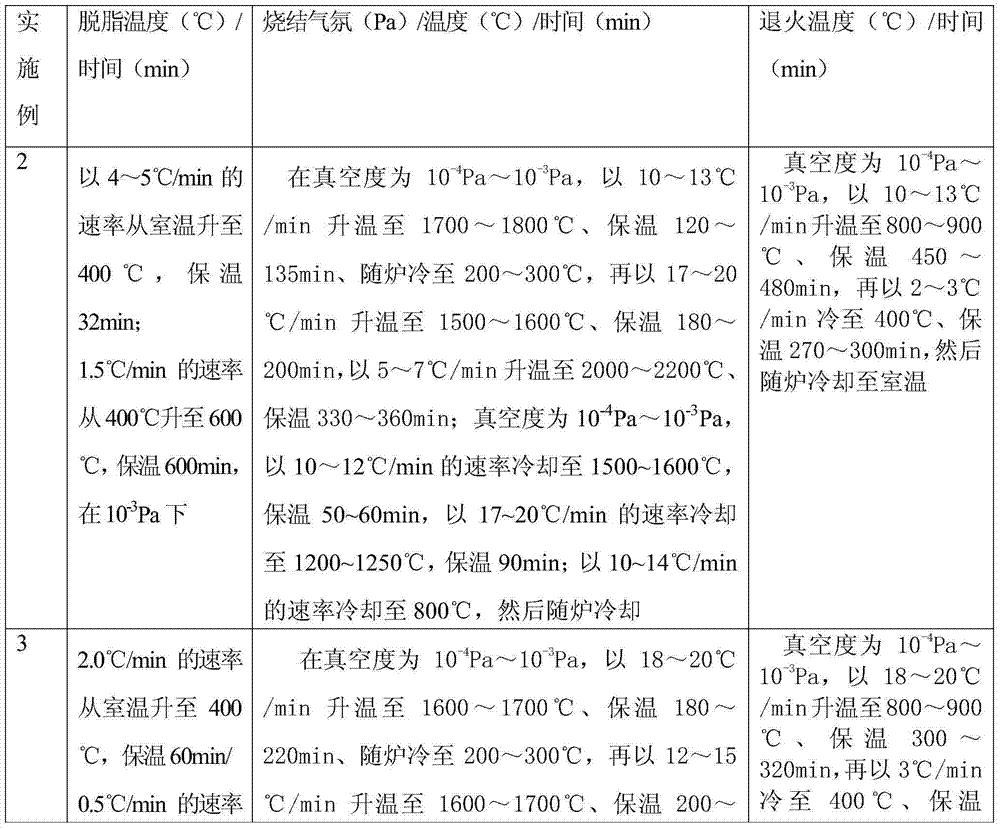

Examples

Embodiment 1

[0024] A preparation method of a porous tantalum medical implant material is carried out as follows:

[0025] a. Mix pure tantalum powder (powder particle size 8-10 μm) with methyl cellulose aqueous solution with a mass percent concentration of 4% at a mass ratio of 7:1, stir well and evenly, and prepare a tantalum powder slurry;

[0026] b. Put the fully three-dimensionally connected polymer template bracket with a porosity of 20% to 50% into the steel mold, then pour the prepared tantalum powder slurry into the steel mold and flow over the polymer template bracket Finally, apply pressure slowly and evenly around the steel mold so that the tantalum powder is fully filled into the polymer template. The applied pressure is increased from 0MPa to 10Mpa at a constant speed, and the time used for the pressurization process is 5h, so that the tantalum powder particles and The particles are closely combined with each other, and the moisture in the tantalum powder slurry seeps out of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com