Method for manufacturing high-voltage large-power thyristor by adopting sintering process

A high-power, thyristor technology, which is applied in the field of manufacturing high-voltage and high-power thyristors by sintering process, can solve the problems of high price and long supply cycle, and achieve the effects of low manufacturing cost, high yield and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

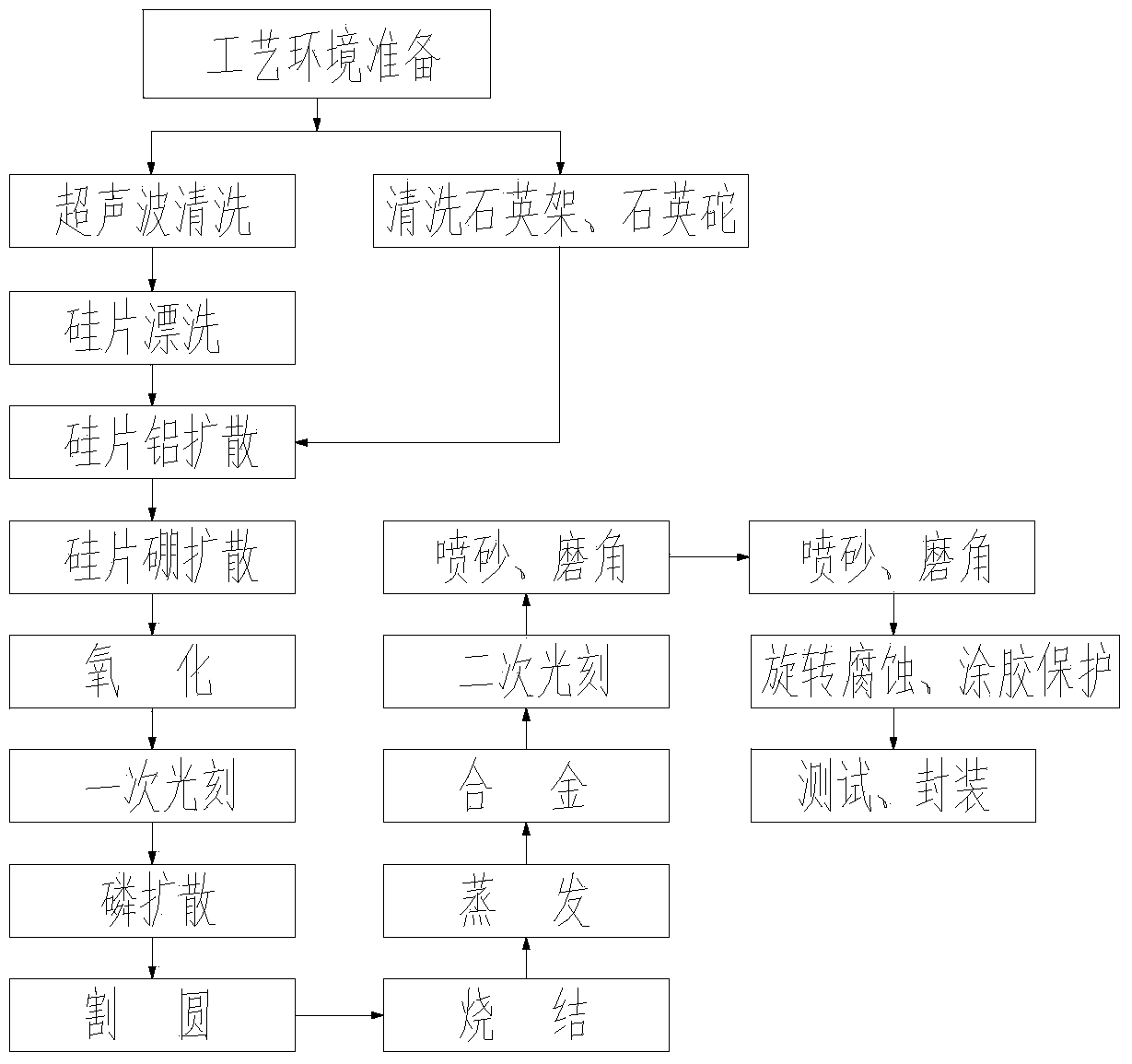

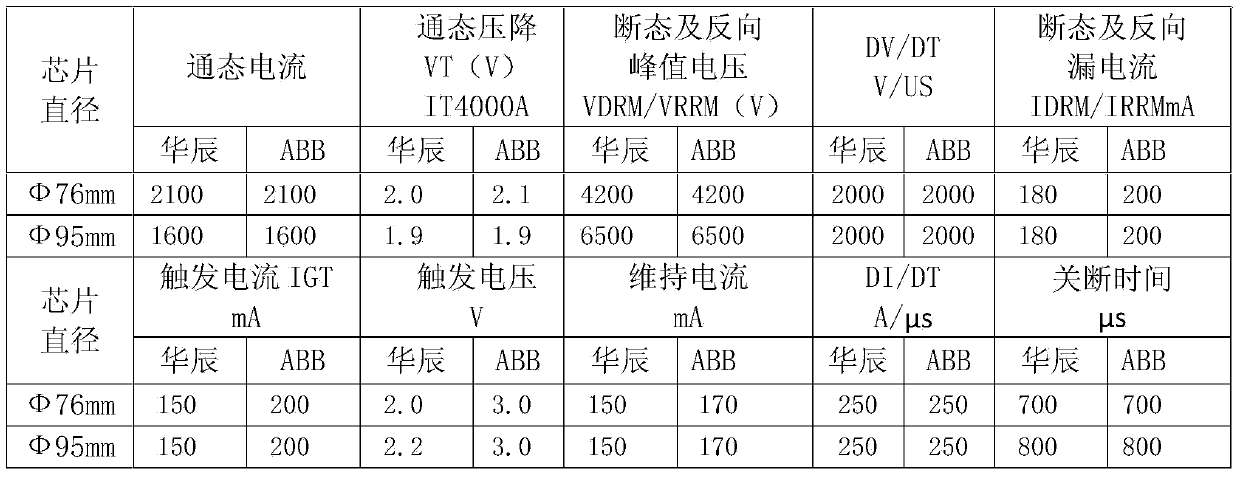

[0094] [Example 1] The process of applying the method of the present invention to produce 50 high-power 4200V high-voltage thyristors is as follows:

[0095] (1) Filtration process environment

[0096] The air is filtered in two stages, and the filtered air is 10 grades.

[0097] (2) Ultrasonic cleaning

[0098] Firstly, the silicon wafer was ultrasonically desanded for 1 hour, ultrasonically cleaned with hydrofluoric acid for 1 hour, rinsed with deionized water at room temperature and 70°C respectively, ultrasonically cleaned with deionized water for 2 hours, and deionized water was replaced every 30 minutes, and then, Rinse four times alternately with hot and cold deionized water;

[0099] (3) Silicon wafer rinsing

[0100] Put the silicon wafer after ultrasonic desanding into 1# solution, boil it on the heater for 5 minutes, rinse it with deionized water 10 times, replace it with clean 1# solution and cook it again, and then alternately use hot and cold deionized water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com