Method for producing flat-plate-type solid oxide fuel cell anode support electrolyte composite membrane

A solid oxide and anode support technology, applied in solid electrolyte fuel cells, fuel cells, electrolytes, etc., can solve the problems of not being suitable for industrialized large-scale production, reducing the reliability of diaphragms, and affecting cathode preparation, etc., to achieve mass production, Easy to operate and optimize the effect of single battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

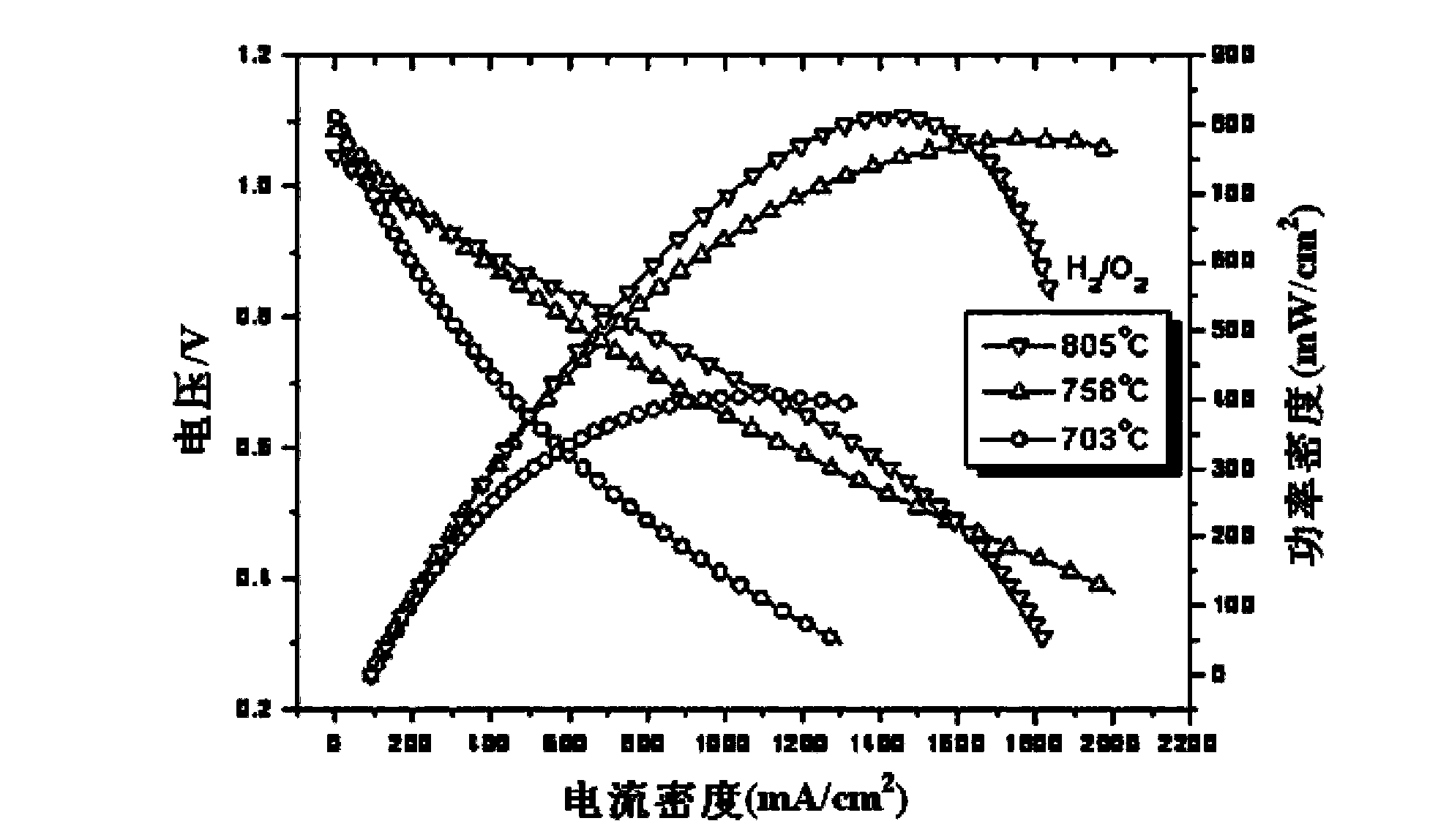

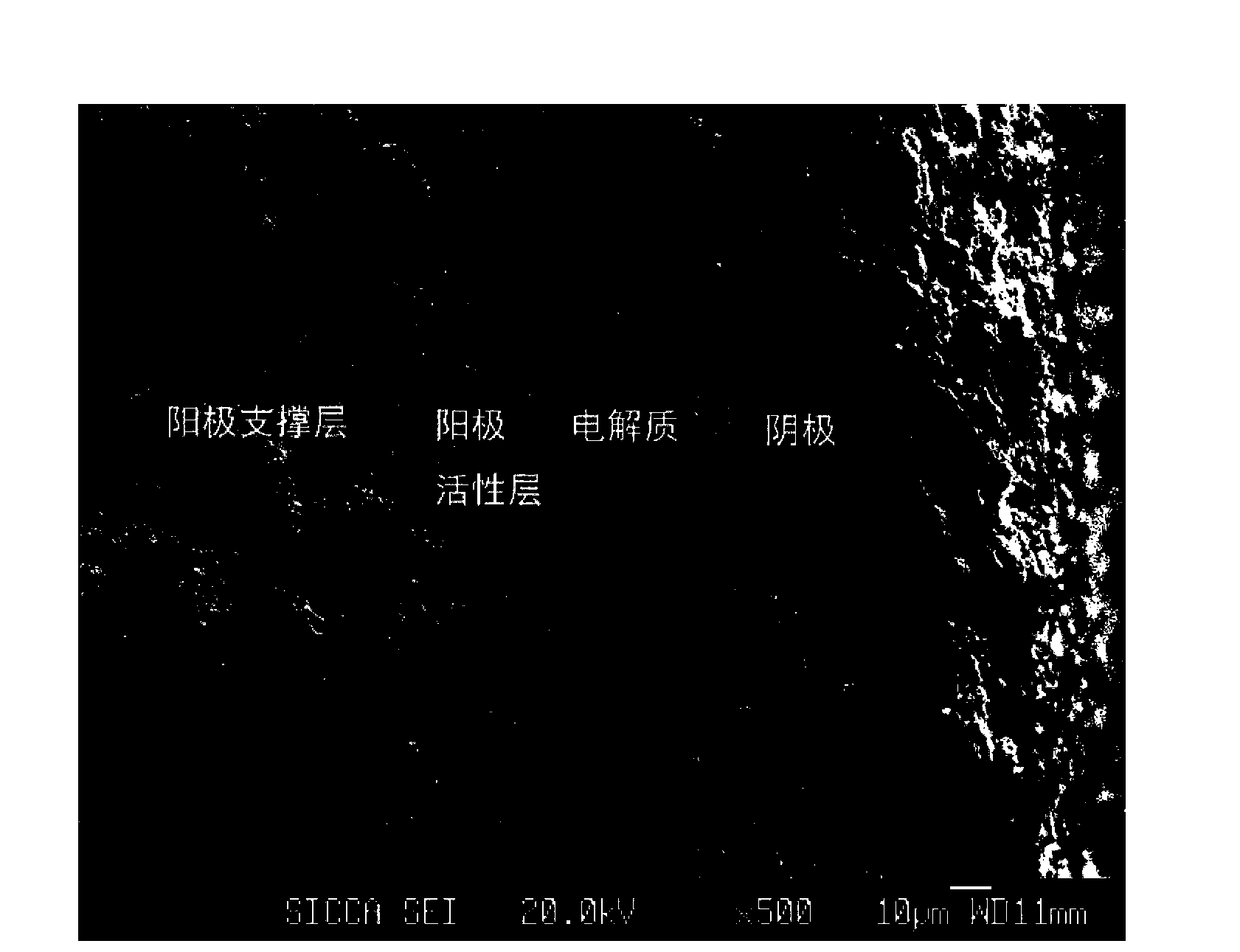

[0036] Weigh 40g of YSZ, 2g of dispersant TEA, 30g of solvent ethanol, 50g of methyl ethyl ketone and 100g of zirconia grinding balls and mill on a planetary ball mill for 1 hour, then add 4.8g of binder PVB, 4g of plasticizer PEG and 4g of DOP, and continue to mill for 2 hours. A slurry for preparing an electrolyte layer was obtained.

[0037] Weigh NiO20g and SSZ (SSZ, 10mol%Sc 2 o 3 Stable ZrO 2 ) 30g, pore-forming agent starch 3g, add solvent ethanol 20g and butanone 35g, dispersant TEA2g, zirconia grinding ball 100g ball mill on planetary ball mill for 1 hour, then add binder PVB4g, plasticizer PEG3.5g and DOP3 .5g, and continued ball milling for 2 hours to obtain the slurry for preparing the anode active layer.

[0038] Weigh NiO50g and YSZ (YSZ, 8mol%Y 2 o 3 Stable ZrO 2 ) 50g, pore-forming agent starch 10g, add solvent ethanol 50g and butanone 100g, dispersant TEA5g, zirconia grinding ball 200g ball mill on the planetary ball mill for 1 hour, then add binder PVB1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Rate density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com