Packaging process for three-way catalytic converter

A technology of three-way catalytic converter and packaging technology, which is applied in the direction of mufflers, exhaust devices, engine components, etc. It can solve the problems of uneven deformation of the liner, large changes, and easy breakage of the carrier, and achieve the reduction of welding straight welds, The effect of consistent and unchanged length and unbreakable carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

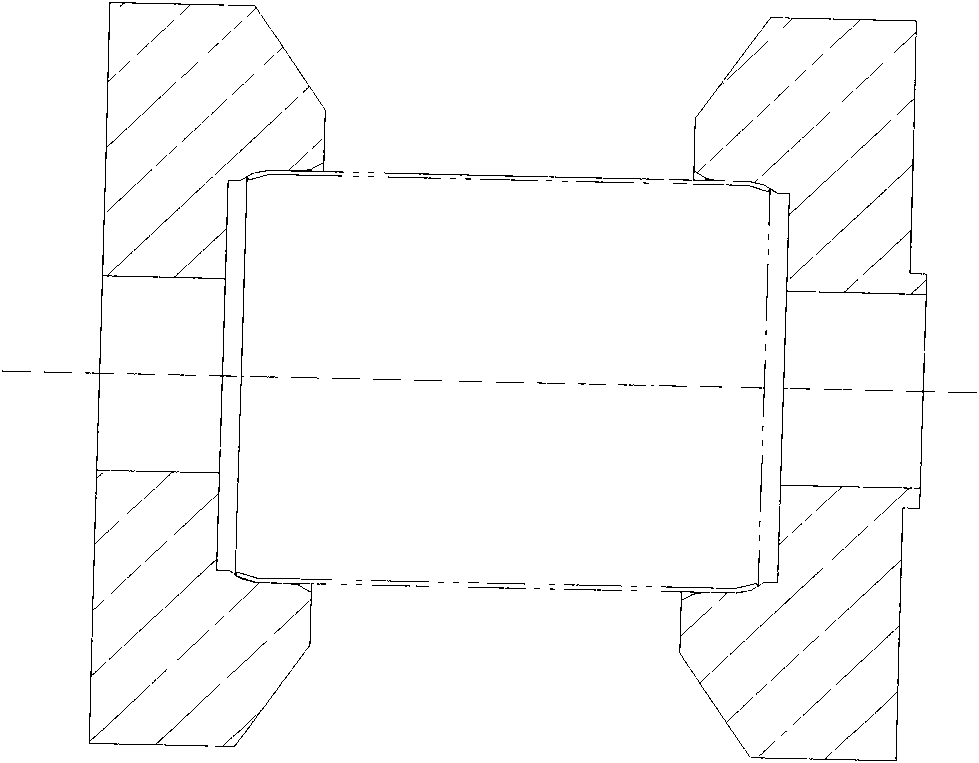

[0058] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

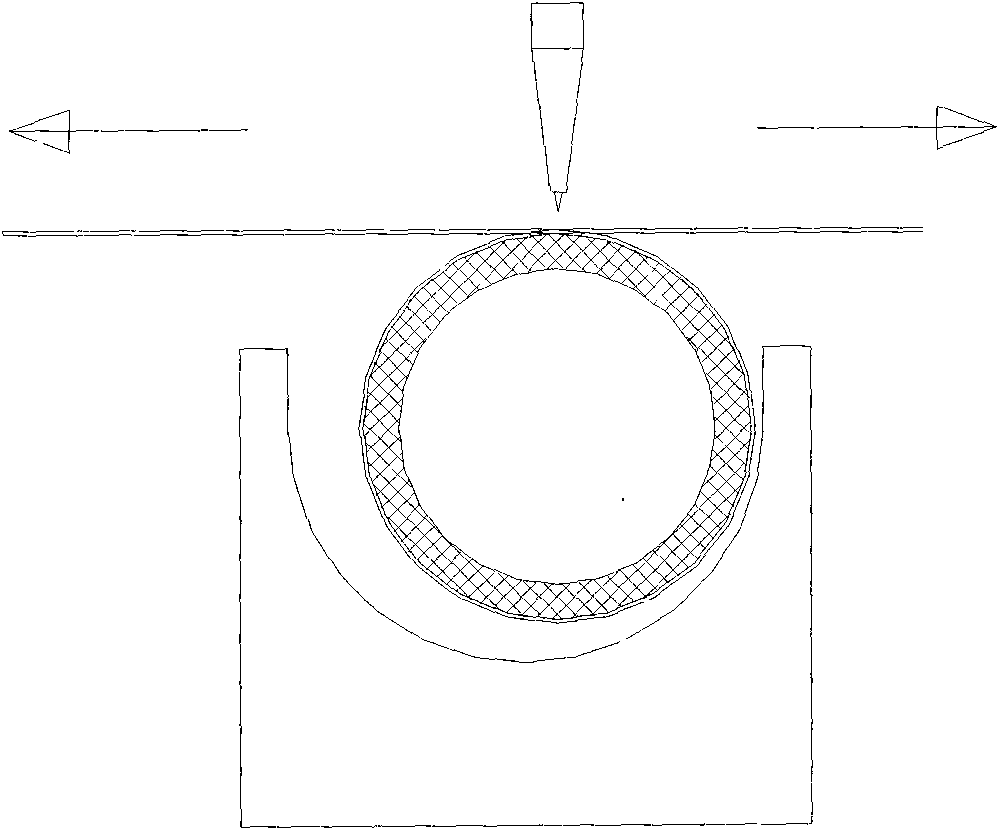

[0059] The packaging process of a three-way catalytic converter provided in the embodiment of the present invention is characterized in that the process flow of the packaging process:

[0060] 1. The measurement of the outer (diameter) diameter of the carrier and the weight of the liner,

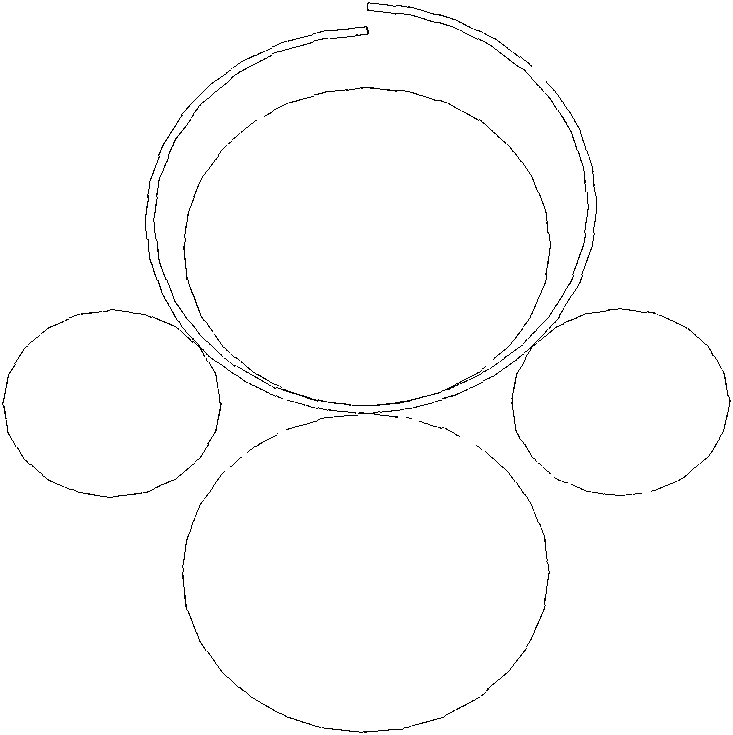

[0061] The outer diameter of the carrier is measured non-contact, by Figure 5 As shown, the transmitter 14 is used to emit two sets of laser beams, which are emitted from one end of the carrier 12, pass through both sides of the carrier, and are received by the receiver 15 at the other end, and the outer diameter of the carrier can be calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com