High elastomer material equiaxial tensile testing machine

A tensile testing machine and bulk material technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problems of uneven deformation, inaccurate stress measurement, unfavorable measurement of material strain, etc., to achieve stress and deformation. The effect of uniform, high strain measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

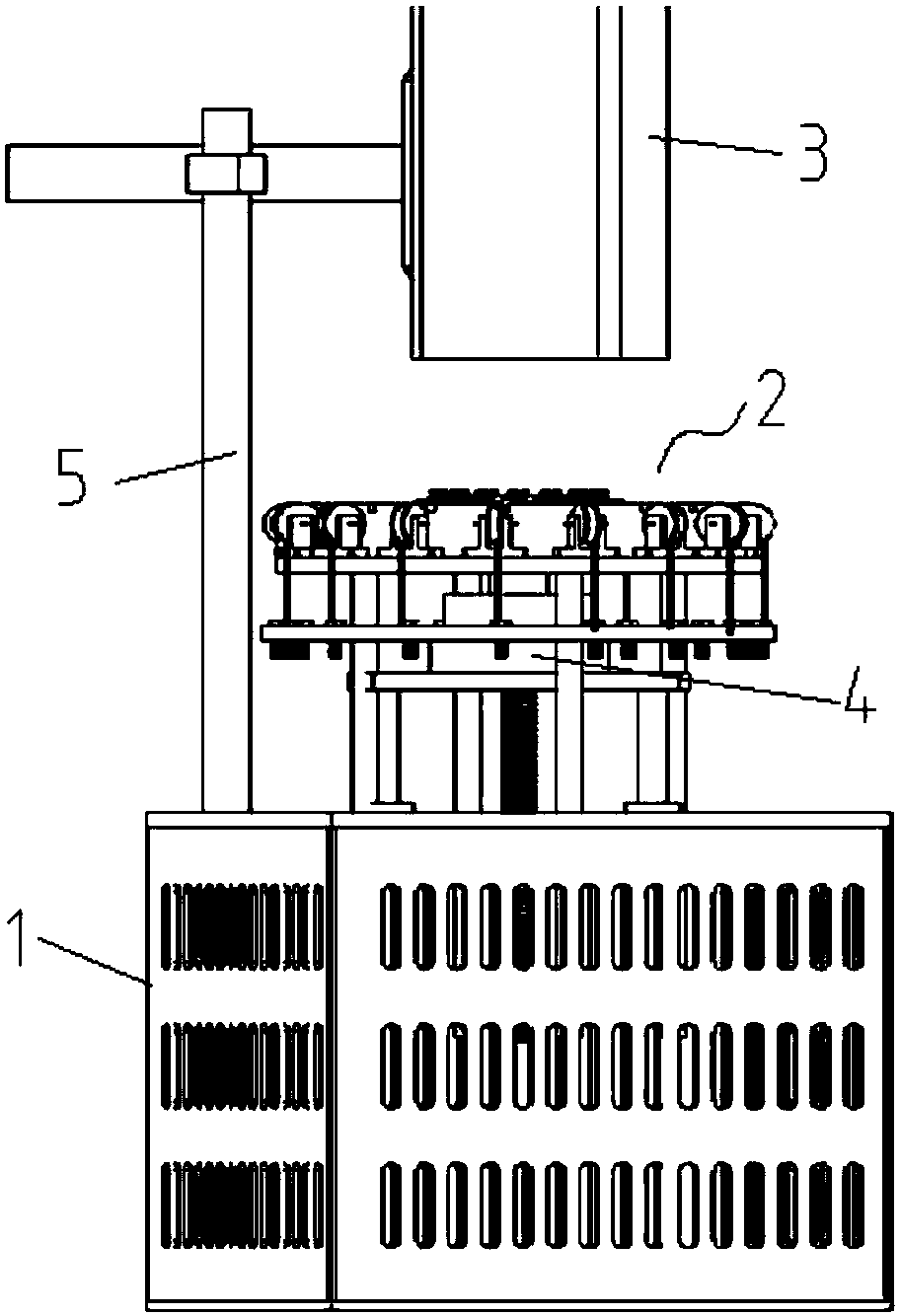

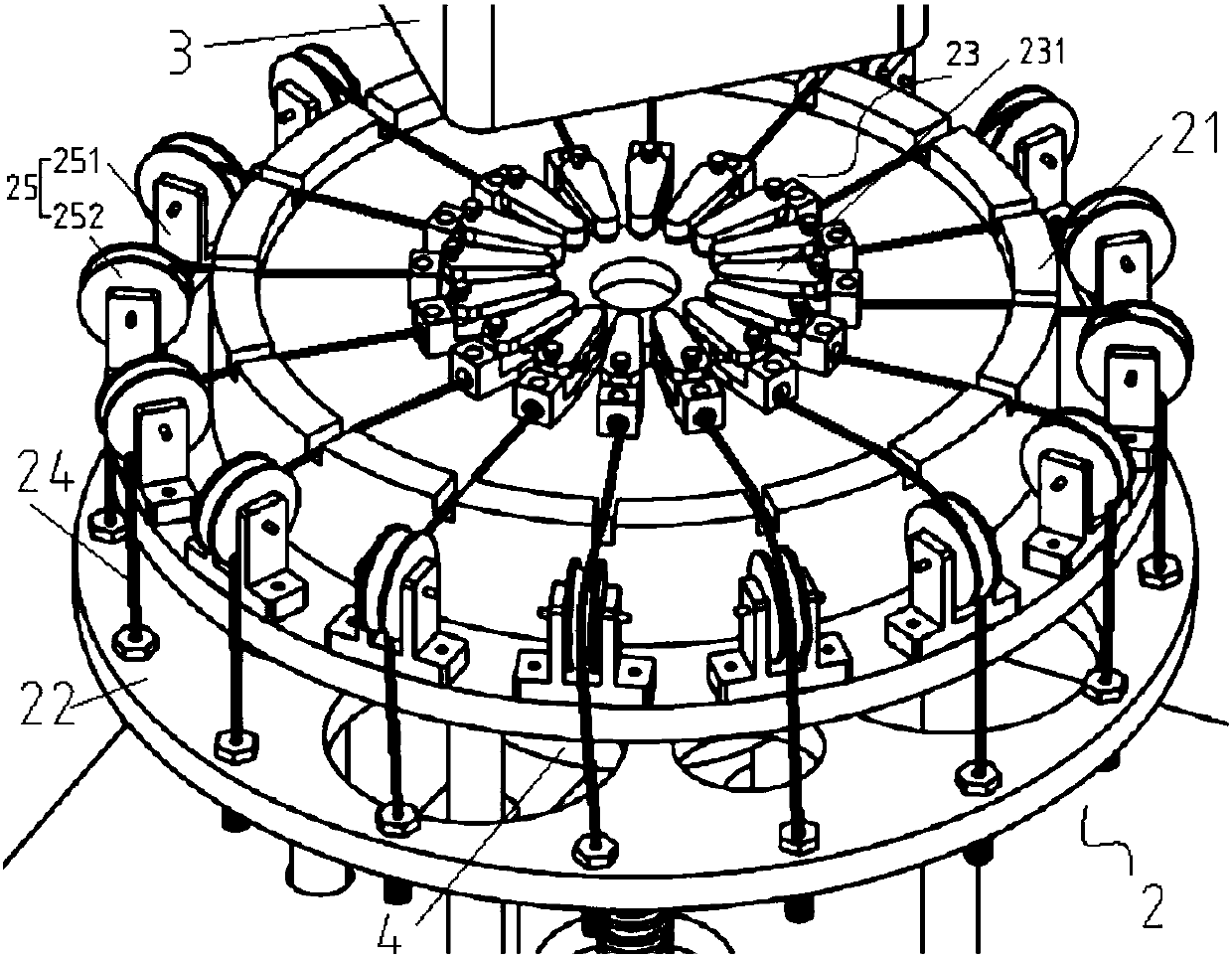

[0035] figure 1 Schematic diagram of the structure of the equiaxial tensile testing machine for high elastomeric materials provided in Embodiment 1 of the present invention; figure 2 for figure 1 Schematic diagram of the structure of the stretching mechanism; Figure 1-Figure 2 As shown, the high elastic body material equiaxial tensile testing machine provided by the present invention includes a frame 1 and a tensile mechanism 2 installed on the frame 1;

[0036] The stretching mechanism 2 includes a circular platform 21, a rotating disk 22, a circular clamp 23, a stay cord 24 and a pulley mechanism 25. The circular platform 21 and the rotating disk 22 are arranged coaxially and installed on the machine in sequence. On the frame 1, the turntable 22 is driven by a driving mechanism installed in the frame 1, the circular clamp 23 is installed on the circular platform 21, and one end of the stay rope 24 is connected to the circular clamp 23, and the other end of the pull cord...

Embodiment 2

[0063] The equiaxial tensile testing machine for high elastic body material provided in this embodiment 2 is a further improvement of the equiaxial tensile testing machine for high elastic body material provided in embodiment 1. On the basis of embodiment 1, this embodiment 2 The provided equiaxial tensile testing machine for high elastic body materials includes a frame 1 and a tensile mechanism 2 installed on the frame 1;

[0064] The stretching mechanism 2 includes a circular platform 21, a rotating disk 22, a circular clamp 23, a stay cord 24 and a pulley mechanism 25. The circular platform 21 and the rotating disk 22 are arranged coaxially and installed on the machine in sequence. On the frame 1, the turntable 22 is driven by a driving mechanism installed in the frame 1, the circular clamp 23 is installed on the circular platform 21, and one end of the stay rope 24 is connected to the circular clamp 23, and the other end of the pull cord 24 is connected to the turntable 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com