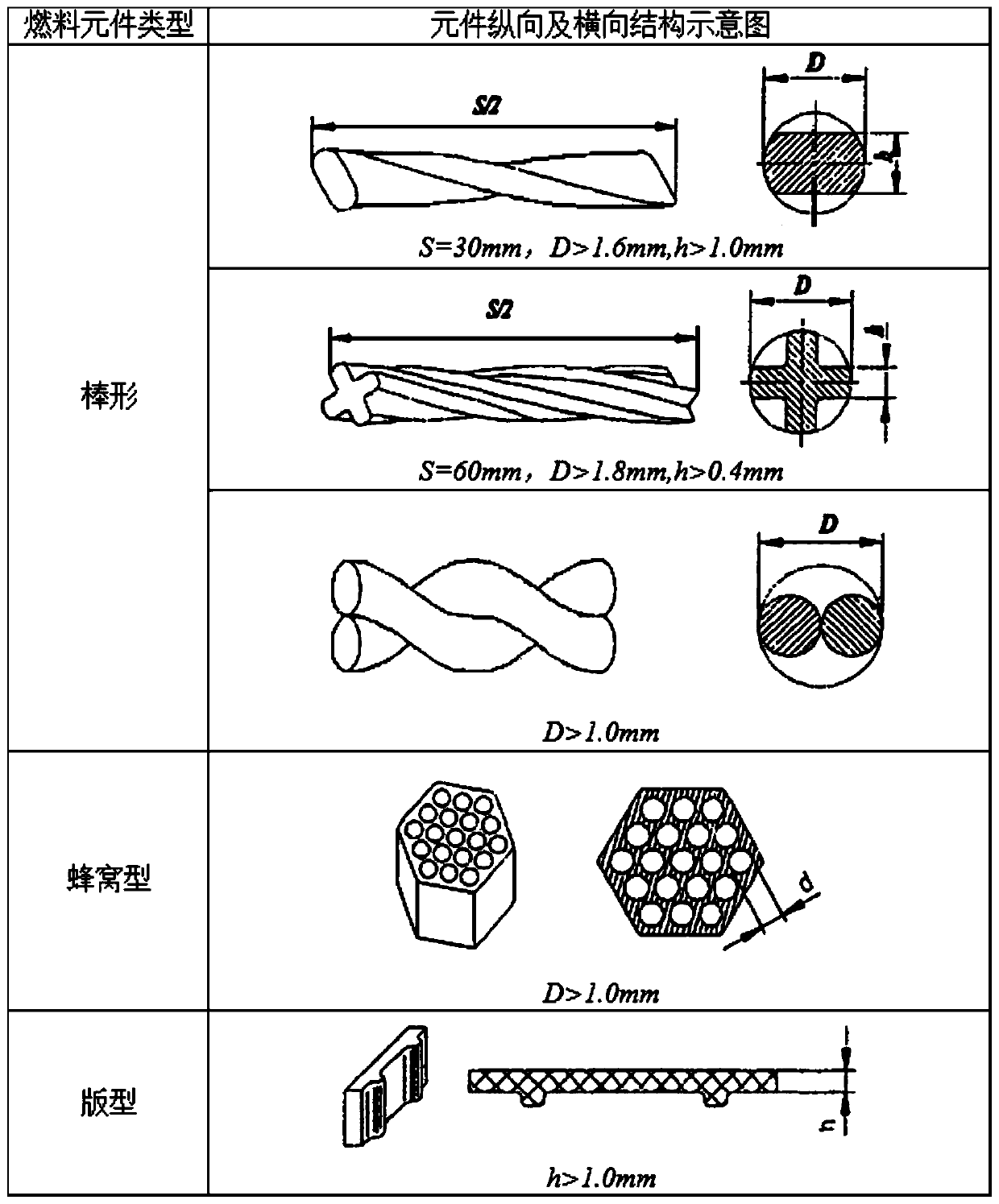

Preparation method of honeycomb fuel pellet

A technology of fuel pellets and honeycomb shape, which is applied in the field of preparation of honeycomb fuel pellets, can solve the problems of enlarging the scrap rate of grinding, reducing the production yield of pellets, complex shape of pellets, etc., and achieves the realization of external dimension control, Easy control of external dimensions and uniform internal density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Preparation of honeycomb fuel pellets (1)

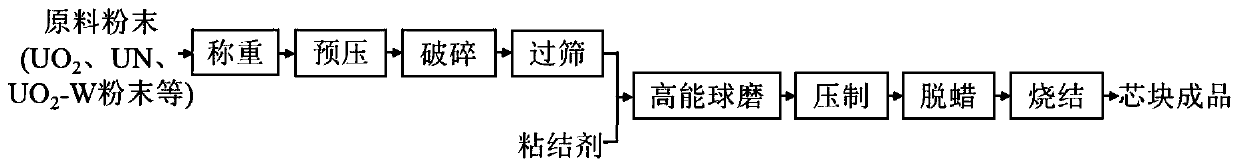

[0045] Weigh UO 2 Powder 50g, paraffin wax powder 0.5g. Will UO 2 The powder is filled into the mold and pre-pressed on a hydraulic press with a pre-pressing pressure of 50MPa. The pre-pressed compact is crushed, and the large particles obtained by crushing are sieved and poured into ZrO together with 0.5g of paraffin wax powder 2 Ball mill jar, put ZrO 2 The balls are subjected to high-energy ball milling, and the conditions are: the volume ratio of the ball to material is 3:1, the milling speed is 300 rpm, and the ball milling time is 48 hours. The powder obtained by ball milling is sieved for later use.

[0046]Weigh 4 g of the granulated powder and fill it into a cemented carbide mold, apply a pressure of 500 MPa to the mold on a hydraulic press, hold the pressure for 5 seconds, and demould to obtain a pellet compact.

[0047] First dewax the pellet compact, the dewaxing temperature is 600°C, the dewaxi...

Embodiment 2

[0048] Embodiment 2: the preparation of honeycomb fuel pellet (two)

[0049] Weigh 50g of UN powder and 1g of paraffin wax powder. Fill the UN powder into the mold and pre-press on the hydraulic press with a pre-press pressure of 80MPa. The pre-pressed compact is crushed, and the large particles obtained by crushing are sieved and poured into ZrO together with 1g of paraffin wax powder. 2 Ball mill jar, put ZrO 2 The balls are subjected to high-energy ball milling, and the conditions are: the volume ratio of the ball to material is 4:1, the milling speed is 400 rpm, and the ball milling time is 32 hours. The powder obtained by ball milling is sieved for later use.

[0050] Weigh 4 g of the granulated powder and fill it into a cemented carbide mold, apply a pressure of 300 MPa to the mold on a hydraulic press, hold the pressure for 30 seconds, and then release the mold to obtain a pellet compact.

[0051] Dewax the pellet compact first, the dewaxing temperature is 400°C, th...

Embodiment 3

[0052] Embodiment 3: Preparation of honeycomb fuel pellets (three)

[0053] Weigh UO 2 -W powder 50g, paraffin wax powder 2.5g. Will UO 2 -W powder is filled into the mold and pre-pressed on a hydraulic press with a pre-pressing pressure of 100MPa. The pre-press compact is crushed, and the large particles obtained by crushing are sieved and poured into ZrO together with 2.5g of paraffin wax powder. 2 Ball mill jar, put ZrO 2 The balls are subjected to high-energy ball milling, and the conditions are: the volume ratio of the ball to material is 5:1, the ball milling speed is 500 rpm, and the ball milling time is 16 hours. The powder obtained by ball milling is sieved for later use.

[0054] Weigh 4 g of the granulated powder and fill it into a cemented carbide mold, apply a pressure of 50 MPa to the mold on a hydraulic press, hold the pressure for 60 seconds, and then demould to obtain a pellet compact.

[0055] Put the pellet compact into a tungsten crucible and start de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com