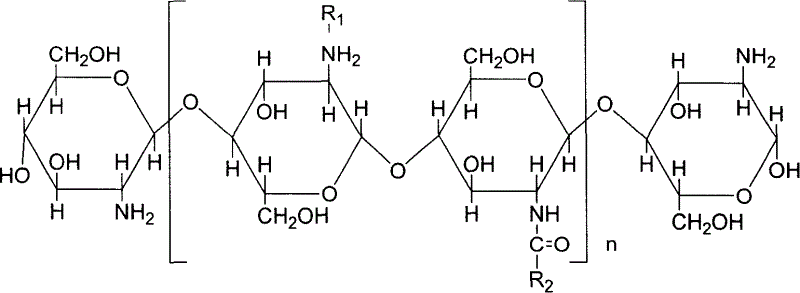

Fluorescence labeling hydrophobic modified chitin polymer, its preparation method and application

A hydrophobic modification and fluorescent labeling technology, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of high viscosity and large molecular weight, and achieve the effect of simple method, mild reaction conditions and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] 1. Preparation of chitosan oligosaccharide

[0028] Add 6g of chitosan (average molecular weight 450kDa) to 200mL of 1.25% (v / v) hydrochloric acid aqueous solution, stir and dissolve at 55-60°C, adjust the pH to 5.0 with dilute ammonia water or dilute hydrochloric acid, press cellulase and shell The ratio of polysaccharides is 0.5:100 (w / w) to add cellulase, and after controlling the reaction time for 8 hours, the reaction product is 4000r×min -1 After centrifugation for 10 minutes, the supernatant was pretreated with a 0.45 μm microporous membrane, graded by ultrafiltration with ultrafiltration membranes of different molecular weights, and the ultrafiltrate was freeze-dried to obtain chitosan oligosaccharides with a certain molecular weight. And the average molecular weight was determined to be 50.6 kDa by gel permeation chromatography.

[0029] 2. Preparation of fluorescently labeled hydrophobic modified chitosan oligosaccharides

[0030] Get above-mentioned chitosa...

example 2

[0037] 1. Preparation of chitosan oligosaccharide

[0038] Add 6g of chitosan (average molecular weight 450kDa) to 200mL of 1.25% (v / v) hydrochloric acid aqueous solution, stir and dissolve at 55-60°C, adjust the pH to 5.0 with dilute ammonia water or dilute hydrochloric acid, press cellulase and shell Add cellulase at a glycan ratio of 0.5:100 (w / w), and control the reaction time for 24 hours. -1 After centrifugation for 10 minutes, the supernatant was pretreated with a 0.45 μm microporous membrane, graded by ultrafiltration with ultrafiltration membranes of different molecular weights, and the ultrafiltrate was freeze-dried to obtain chitosan oligosaccharides with a certain molecular weight. And the average molecular weight was determined to be 10.1 kDa by gel permeation chromatography.

[0039] 2. Preparation of fluorescently labeled hydrophobic modified chitosan oligosaccharides

[0040] Take 0.5g chitosan (average molecular weight 10.1kDa), accurately weighed. After ad...

example 3

[0046] 1. Preparation of chitosan oligosaccharide

[0047] Add 6g of chitosan (average molecular weight 450kDa) to 200mL of 1.25% (v / v) hydrochloric acid aqueous solution, stir and dissolve at 55-60°C, adjust the pH to 5.0 with dilute ammonia water or dilute hydrochloric acid, press cellulase and shell Add cellulase at a glycan ratio of 0.5:100 (w / w), and control the reaction time for 20 hours. -1 After centrifugation for 10 minutes, the supernatant was pretreated with a 0.45 μm microporous membrane, graded by ultrafiltration with ultrafiltration membranes of different molecular weights, and the ultrafiltrate was freeze-dried to obtain chitosan oligosaccharides with different molecular weights. And the average molecular weight was determined to be 18.8 kDa by gel permeation chromatography.

[0048] 2. Preparation of fluorescently labeled hydrophobic modified chitosan oligosaccharides

[0049] Get 0.5g chitosan oligosaccharide (average molecular weight 18.8kDa), accurately we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com