Method for preparing medical polymer material by ion implantation technique

A technology of polymer materials and ion implantation equipment, applied in the field of medical polymer materials processing, can solve the problem of neglecting material performance requirements, failing to solve the problem of surface infection of silicone rubber, and failing to solve the problem of biocompatibility of anti-infection performance on the surface of materials, etc. It can be beneficial to the growth and reproduction of cells and tissues, improve the anti-infection performance, and ensure the effect of biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

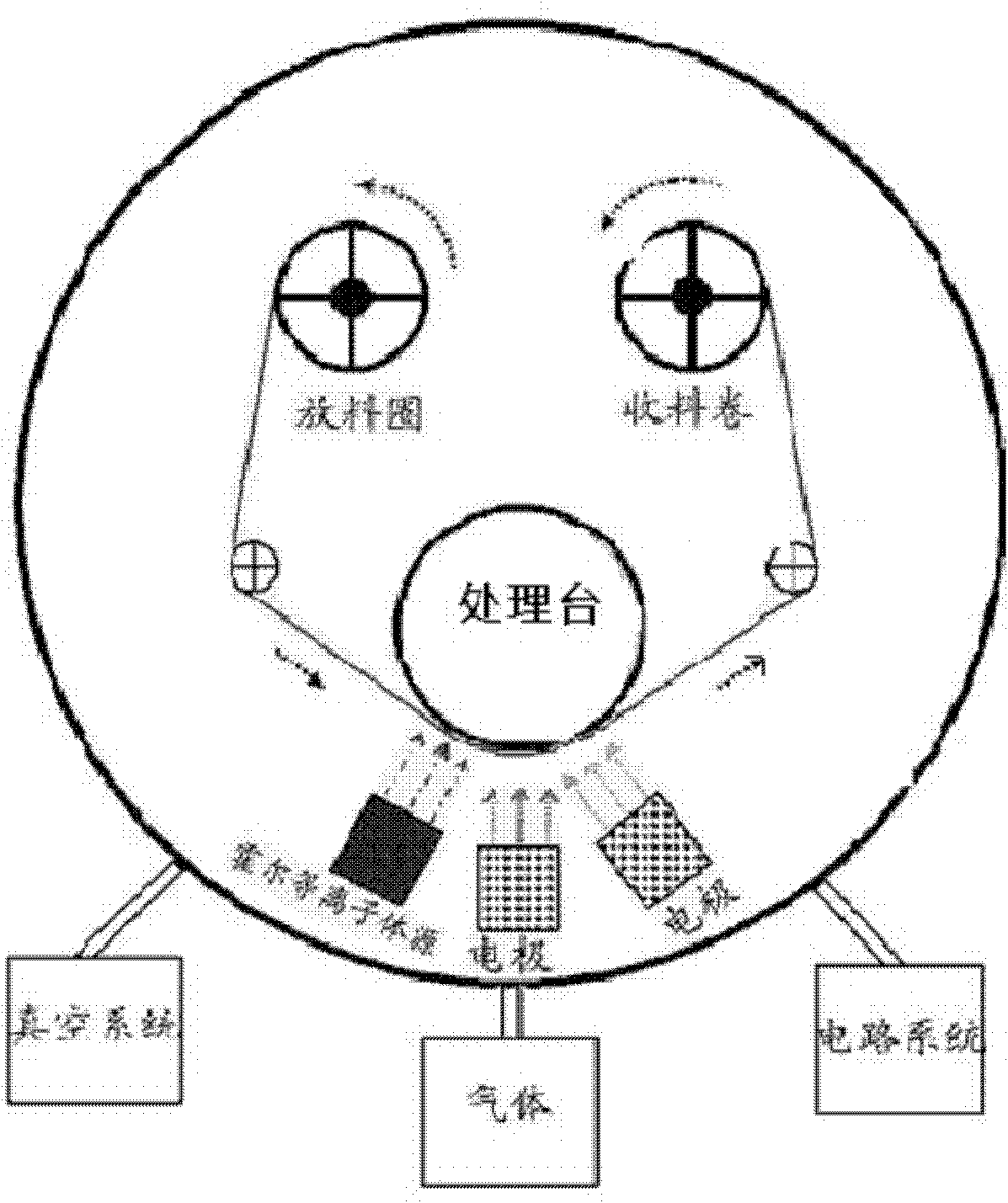

[0040] The preparation of medical polymer materials by ion implantation technology includes the following steps:

[0041] Move the polyethylene film with a thickness of 1 μm through the processing table in the vacuum chamber of the ion implantation equipment at 1 m / min, install the silver electrode on the ion implantation machine, then seal the vacuum chamber of the equipment, and evacuate to 1×10 -5 Pa, through 10.0SCCM of nitrogen and 10.0SCCM of argon, and finally maintain the working vacuum at 1×10 -2 Around Pa, turn on the Hall plasma source with a power of 300W, and at the same time turn on the power of the ion implanter, the accelerating voltage is 15KV, and the ion implantation dose is 1×10 15 ~1×10 17 ions / cm 2After the treatment, turn off the power of the ion implanter and the Hall plasma source, ventilate the atmosphere to return the vacuum chamber to the atmospheric pressure, and obtain the desired anti-infection and biocompatible polyethylene film.

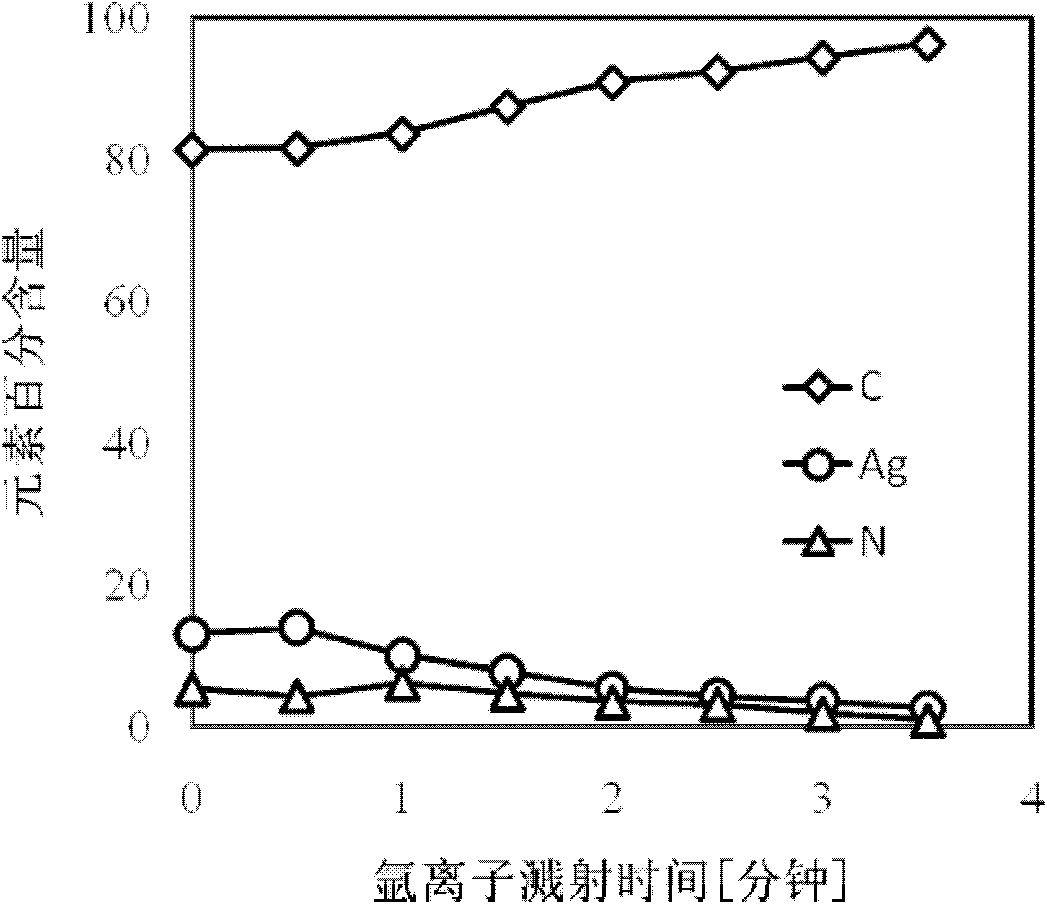

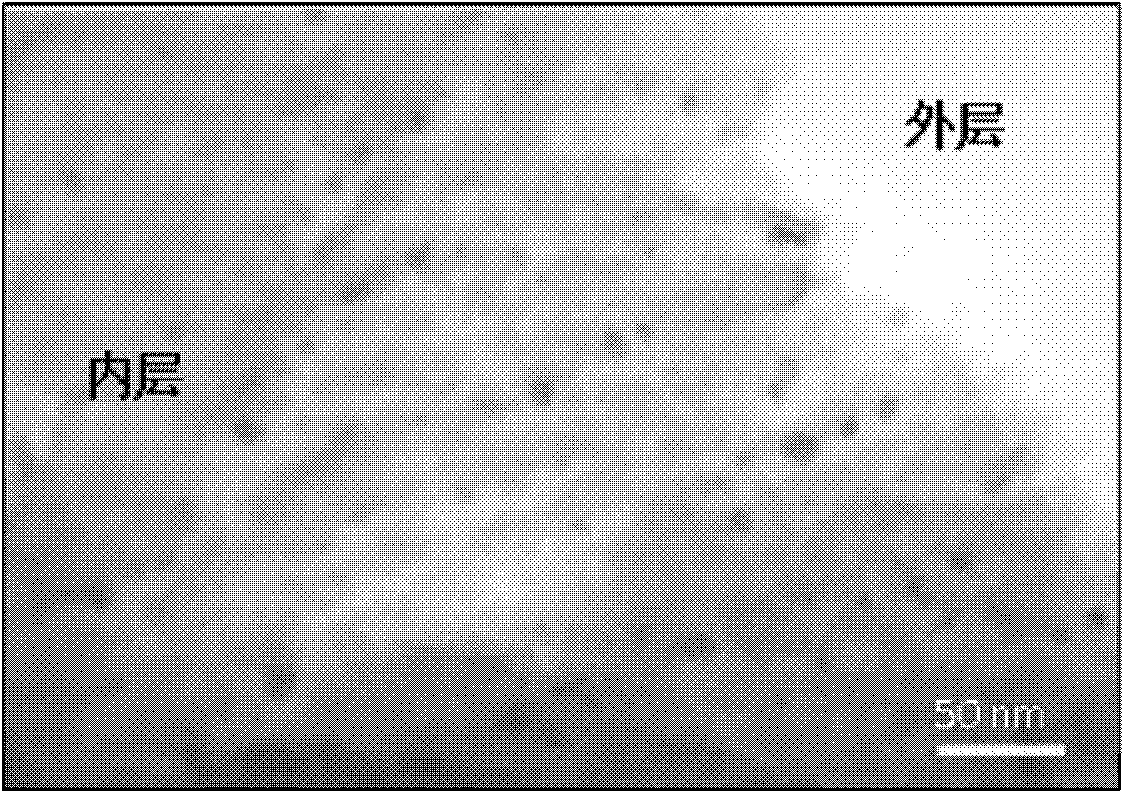

[0042] fi...

Embodiment 2

[0049] The preparation of medical polymer materials by ion implantation technology includes the following steps:

[0050] Fix the PLA film with a thickness of 0.5 μm on the processing table in the vacuum chamber of the ion implantation equipment, install the silver electrode and the zinc electrode on the ion implantation machine, then seal the vacuum chamber of the equipment, and evacuate to 5×10 -6 Pa, pass through 5.0SCCM of ammonia, 5.0SCCM of acetic acid gas and 10.0SCCM of argon, and finally maintain the working vacuum at 5×10 -3 At about Pa, turn on the radio frequency plasma source, the power is 500W, and after 5 minutes of treatment, turn on the power of the ion implanter, the accelerating voltage is 30KV, and the ion implantation dose is 1×10 16 ~5×10 16 ions / cm 2 , after 5 seconds of treatment, turn off the power of the ion implanter and the radio frequency plasma source, and keep it under this condition for 60 minutes, ventilate the atmosphere to return the vacuum...

Embodiment 3

[0053] The preparation of medical polymer materials by ion implantation technology includes the following steps:

[0054] Move the polyamide-66 artificial intervertebral body support at 2 m / min through the processing table in the vacuum chamber of the ion implantation equipment, install each of the silver electrode, graphite electrode and phosphorus electrode on the ion implantation machine, and then seal the equipment vacuum chamber, and evacuated to 5 x 10 -4 Pa, through 10.0SCCM of nitrogen, 5.0SCCM of acetylene gas and 5.0SCCM of argon, and finally maintain the working vacuum at 1×10 -4 At about Pa, turn on the Hall plasma source, the power is 800W, after 10 minutes of treatment, turn on the power of the ion implanter, the accelerating voltage is 30KV, and the ion implantation dose is 1×10 17 ~5×10 17 ions / cm 2 , after the treatment, turn off the power of the ion implanter, and keep it for 5 minutes, then turn off the power of the Hall plasma source, and keep it for 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com