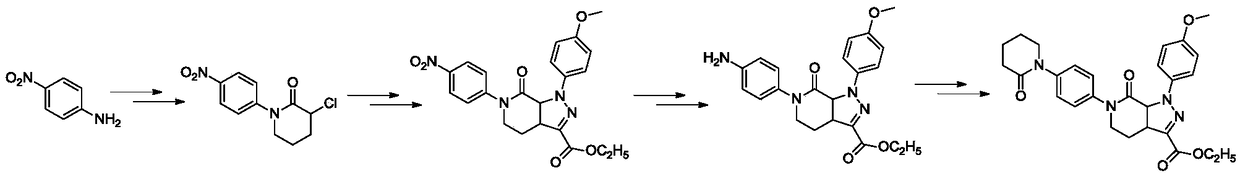

Method of synthesizing apixaban intermediate by microchannel reactor

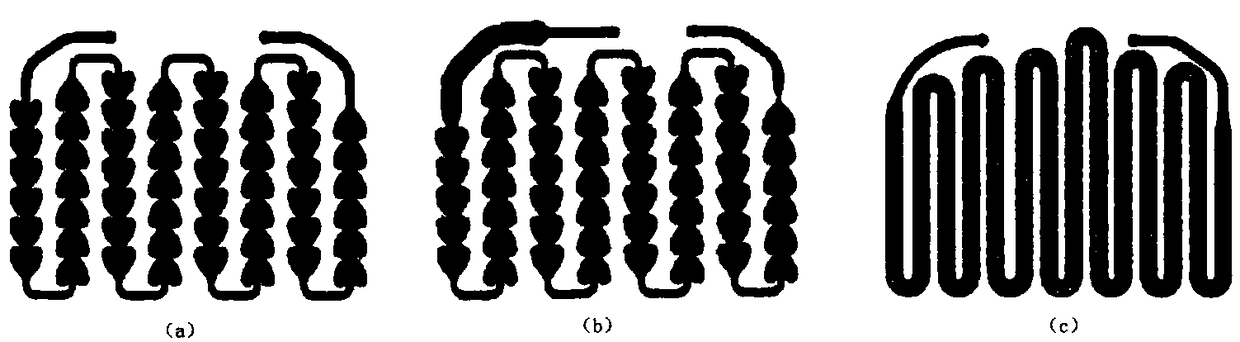

A microchannel reactor, apixaban technology, applied in organic chemistry and other directions, can solve the problems of low catalyst recovery times, long reaction time, violent explosion, etc., and achieve stable online production and post-processing, yield and purity. The effect of improving and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

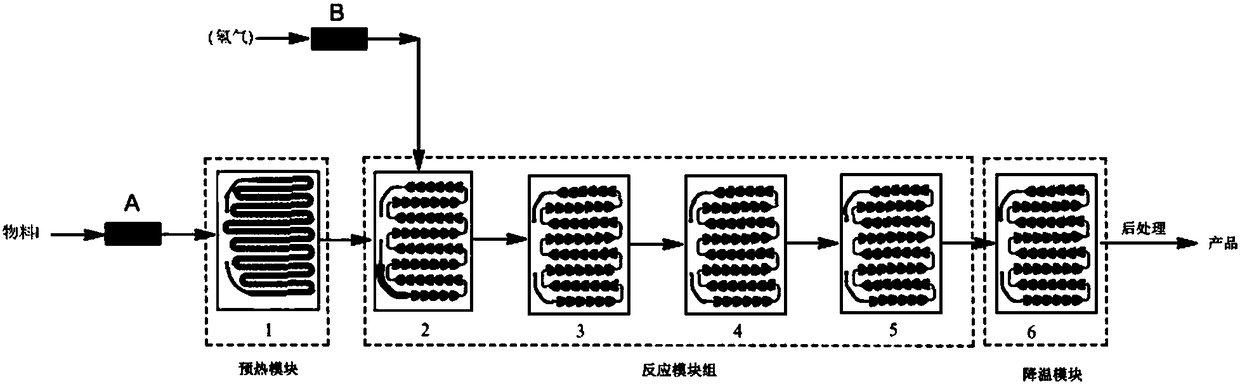

[0041] This embodiment provides a method for synthesizing an intermediate of apixaban in a microchannel reactor, and the specific steps are as follows:

[0042] 1) Weigh the raw material hydrogenation precursor nitro (4,5,6,7-tetrahydro-1-(4-methoxyphenyl)-6-(4-nitrophenyl)-7-oxo Substitute-1H-pyrazolo[3,4-c]pyridine-3-carboxylic acid ethyl ester) 300g, then join in the anhydrous methanol of 5L, then add the Pd mass content of 10g to be the Pd / C catalyst of 5% , fully stirred and mixed to form the material I, and the material I was transported to the preheating module 1 of the microchannel reactor for preheating, and then entered the reaction module group of the microchannel reactor after preheating;

[0043] 2) Hydrogen is delivered to the reaction module group of the microchannel reactor and step 1) the material I after preheating is reacted in the reaction module group, wherein: adjust the flow rate of the slurry pump so that the flow rate of the material I is 35.0g / min , ...

Embodiment 2

[0045] This embodiment provides a method for synthesizing an intermediate of apixaban in a microchannel reactor, and the specific steps are as follows:

[0046] 1) Weigh the raw material hydrogenation precursor nitro (4,5,6,7-tetrahydro-1-(4-methoxyphenyl)-6-(4-nitrophenyl)-7-oxo Generation-1H-pyrazolo[3,4-c]pyridine-3-carboxylic acid ethyl ester) 250g, then join in the absolute ethanol of 4L, then add the Pd mass content of 5g to be the Pd / C catalyst of 10% , fully stirred and mixed to form the material I, and the material I was transported to the preheating module 1 of the microchannel reactor for preheating, and then entered the reaction module group of the microchannel reactor after preheating;

[0047] 2) Hydrogen is delivered to the reaction module group of the microchannel reactor and step 1) reacts with the preheated material I in the reaction module group, wherein: adjust the flow rate of the slurry pump so that the flow rate of the material I is 40.0g / min , adjust H...

Embodiment 3

[0049] This embodiment provides a method for synthesizing an intermediate of apixaban in a microchannel reactor, and the specific steps are as follows:

[0050] 1) Weigh the raw material hydrogenation precursor nitro (4,5,6,7-tetrahydro-1-(4-methoxyphenyl)-6-(4-nitrophenyl)-7-oxo Generation-1H-pyrazolo[3,4-c]pyridine-3-carboxylic acid ethyl ester) 200g, then join in the isopropanol of 3L, add the Pt mass content of 8g subsequently and be the Pt / C catalyst of 6% , fully stirred and mixed to form the material I, and the material I was transported to the preheating module 1 of the microchannel reactor for preheating, and then entered the reaction module group of the microchannel reactor after preheating;

[0051] 2) Hydrogen is delivered to the reaction module group of the microchannel reactor and step 1) the material I after preheating is reacted in the reaction module group, wherein: adjust the flow rate of the slurry pump so that the flow rate of the material I is 35.0g / min ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com