Carbon molecular sieve and preparation method thereof

A carbon molecular sieve and carbonization technology, applied in the field of carbon molecular sieve and its preparation, can solve the problems of difficulty in forming industrialization, pollution discharge and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

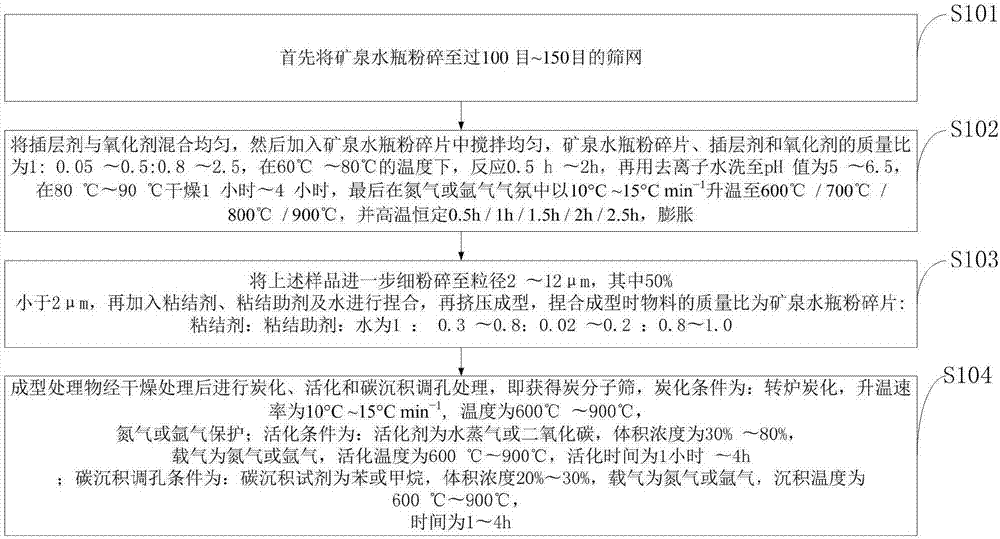

[0066] Such as figure 1 As shown, the preparation method of the carbon molecular sieve provided by the embodiments of the present invention comprises the following steps:

[0067] S101: First crush the mineral water bottle to pass through a sieve of 100 mesh to 150 mesh;

[0068] S102: Mix the intercalation agent and the oxidizing agent evenly, then add the crushed mineral water bottle flakes and stir evenly. °C, react for 0.5h-2h, then wash with deionized water until the pH value is 5-6.5, dry at 80°C-90°C for 1 hour-4 hours, and finally in nitrogen or argon atmosphere at 10°C-15 ℃min -1 Raise the temperature to 600°C / 700°C / 800°C / 900°C, and keep the high temperature constant for 0.5h / 1h / 1.5h / 2h / 2.5h to expand;

[0069] S103: The above samples are further finely crushed to a particle size of 2-12 μm, 50% of which are less than 2 μm, and then kneaded by adding binder, bonding aid and water, and then extruded. The mass ratio of the materials during kneading is mineral spring ...

Embodiment 1

[0118] The preparation method of the carbon molecular sieve provided by the embodiment of the present invention comprises the following steps:

[0119] First crush the mineral water bottle to pass through a 100-mesh sieve;

[0120] Mix the intercalation agent and oxidant evenly, then add the crushed mineral water bottle flakes and stir evenly. The mass ratio of the crushed mineral water bottle flakes, intercalant and oxidant is 1:0.05:0.8, and react at a temperature of 60°C for 0.5h~ 2h, then wash with deionized water until the pH value is 5-6.5, dry at 80°C-90°C for 1-4 hours, and finally dry at 10°C-15°C in a nitrogen or argon atmosphere -1 Raise the temperature to 600°C / 700°C / 800°C / 900°C, and keep the high temperature constant for 0.5h / 1h / 1.5h / 2h / 2.5h to expand;

[0121] The above sample is further finely crushed to a particle size of 2 μm, and then kneaded by adding a binder, a binder and water, and then extruded. Auxiliary: water is 1:0.3~0.8:0.02~0.2:0.8~1.0;

[0122]...

Embodiment 2

[0124] The preparation method of the carbon molecular sieve provided by the embodiment of the present invention comprises the following steps:

[0125] First crush the mineral water bottle to pass through a 150-mesh sieve;

[0126] Mix the intercalation agent and the oxidizing agent evenly, then add the crushed mineral water bottle flakes and stir evenly. The mass ratio of the crushed mineral water bottle flakes, intercalation agent and oxidant is 1:0.2:2.5. React for 2 hours at a temperature of 80°C, and then Wash with deionized water until the pH value is 5-6.5, dry at 90°C for 4 hours, and finally dry at 10°C-15°C in a nitrogen or argon atmosphere. -1 Raise the temperature to 600°C / 700°C / 800°C / 900°C, and keep the high temperature constant for 0.5h / 1h / 1.5h / 2h / 2.5h to expand;

[0127] The above samples are further finely crushed to a particle size of 2-12 μm, 50% of which are less than 2 μm, and then kneaded by adding a binder, a bonding aid and water, and then extruded. Shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com