Method for preparing ordered ferriferrous oxide/chitosan nanometre composite material

A technology of ferroferric oxide and chitosan nanometers, which is applied in the field of preparation of ferroferric oxide/chitosan nanocomposites, can solve the problems of the preparation of magnetic chitosan three-dimensional materials, the decline of material mechanical properties, Weak interface binding force and other problems, to achieve the effect of reducing treatment time, good induction, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

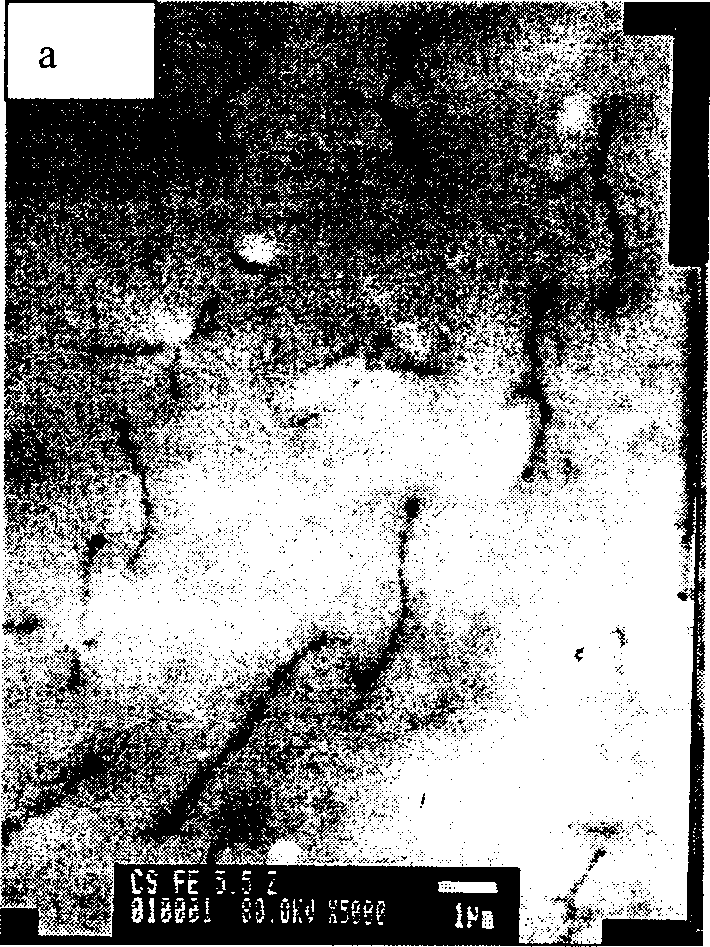

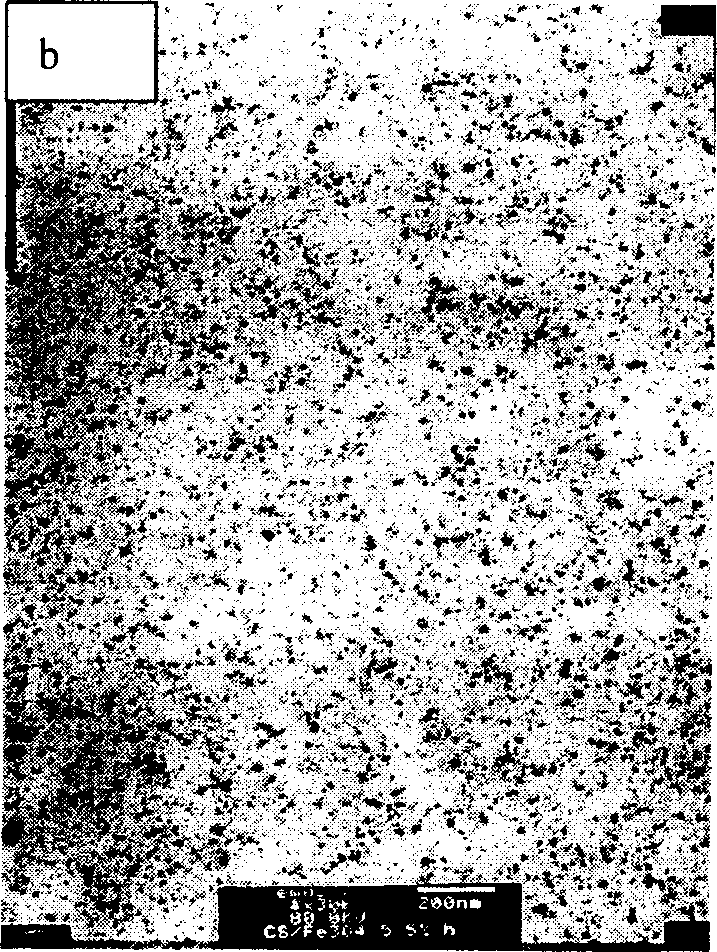

[0011] 1) Weigh 10g of chitosan powder and add it to 163.6ml of 2% (v / v) acetic acid solution and stir for 1h, then add 18.2ml of FeCl with a concentration of 0.25mol / L 2 solution, stirred at a constant speed for 0.5h, then added 18.2ml of FeCl with a pH3 The solution was stirred at a constant speed for 1 hour to obtain the ferric oxide / chitosan precursor solution, which was sealed and allowed to stand for degassing for 6 hours.

[0012] 2) Take a small amount of pure chitosan solution and inject it into a cylindrical mold to form an inner film, pour out the excess chitosan solution, soak in 5% (wt) NaOH solution for 2 hours, and take out the mold.

[0013] 3) Fill the mold with the ferric oxide / chitosan precursor solution, then put the mold filled with the ferric oxide / chitosan precursor solution into 5% (wt) NaOH coagulation solution, let it stand for 0.5 After 10 minutes, the mold was removed, and the formed gel composite material was fixed in the magnetic field generating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com