Preparation method of graphene-containing marine anticorrosive antifouling paint

A marine anti-corrosion and graphene technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve problems such as high environmental risks and poor comprehensive performance, and achieve simple process equipment, low cost, and high The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0042] Step 1: Hydroxylation of graphene surface

[0043] Utilize 98wt% concentrated sulfuric acid and 65wt% concentrated nitric acid, press Prepare aqua regia according to the ratio; then press m:V 王水 The ratio of =1g:600mL weighs (measures) and gets graphene and aqua regia. The weighed graphene was dispersed in aqua regia and ultrasonically treated in a water bath for 30 minutes. Then the system was heated and stirred in a water bath at 60°C for 6 hours, and the graphene was washed with distilled water until neutral, dried in an oven at 60°C, and ground.

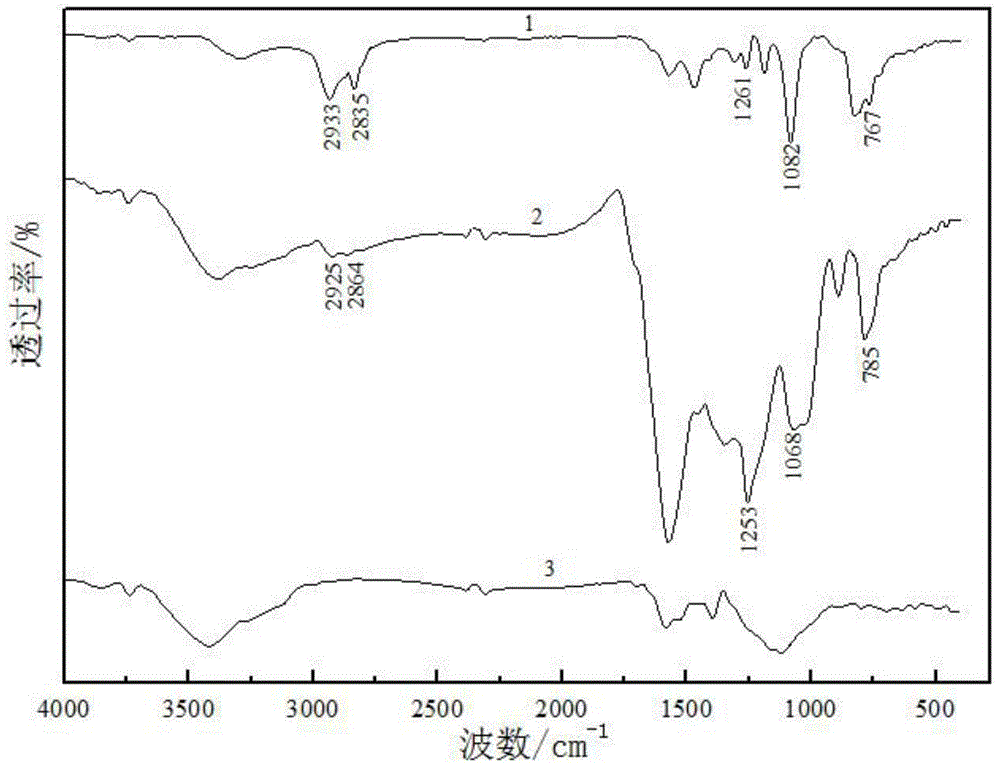

[0044] Step 2: Coupling of Graphene

[0045] The graphene obtained in step one and KH602 (N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane), according to m 石墨烯 :m KH-602 =1mg:3mg mass ratio dissolved in a small amount of deionized water, stirred evenly, ultrasonically dispersed for 30min. Thereafter, it was heated and stirred with a magnetic stirrer at 60°C for 8 hours, and the modified graphene was separated by ...

experiment approach 2

[0053] Step 1: Hydroxylation of graphene surface

[0054] Using 98% concentrated sulfuric acid and 65% concentrated nitric acid, press Prepare aqua regia according to the ratio; then press m:V 王水 The ratio of =1g:610mL weighs (measures) and gets graphene and aqua regia. The weighed graphene was dispersed in aqua regia and ultrasonically treated in a water bath for 30 minutes. Then the system was heated and stirred in a water bath at 60°C for 6 hours, and the graphene was washed with distilled water until neutral, dried in an oven at 60°C, and ground.

[0055] Step 2: Coupling of Graphene

[0056] The graphene obtained in step one and KH602 (N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane), according to m 石墨烯 :m KH-602 The mass ratio of =1mg:4mg was dissolved in a small amount of deionized water, stirred evenly, and ultrasonically dispersed for 30min. Thereafter, it was heated and stirred with a magnetic stirrer at 60°C for 9 hours, and the modified graphene was separa...

experiment approach 3

[0064] Step 1: Hydroxylation of graphene surface

[0065] Using 98% concentrated sulfuric acid and 65% concentrated nitric acid, press Prepare aqua regia according to the ratio; then press m:V 王水 The ratio of =1g:620mL weighs (measures) and gets graphene and aqua regia. The weighed graphene was dispersed in aqua regia and ultrasonically treated in a water bath for 30 minutes. Then the system was heated and stirred in a water bath at 60°C for 6 hours, and the graphene was washed with distilled water until neutral, dried in an oven at 60°C, and ground.

[0066] Step 2: Coupling of Graphene

[0067] The graphene obtained in step one and KH602 (N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane), according to m 石墨烯 :m KH-602 The mass ratio of =1mg:4mg was dissolved in a small amount of deionized water, stirred evenly, and ultrasonically dispersed for 30min. Thereafter, it was heated and stirred with a magnetic stirrer at 60°C for 10 hours, and the modified graphene was sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com