Composite special-shaped spinning device for producing high-brightness high-resilience terylene BCF (Bulked Continuous Filament)

A spinneret, high-rebound technology, used in filament/thread forming, textile and papermaking, fiber processing, etc., can solve the problems of poor brightness and resilience performance of polyester BCF, low price, and high strength, and achieve coverage performance. Good, easy to produce on the machine, high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

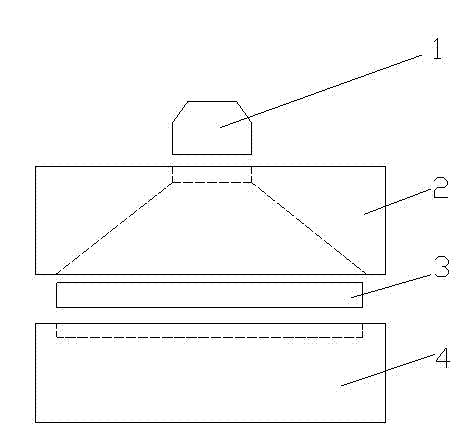

[0017] Below in conjunction with accompanying drawing, the present invention is described in detail, in figure 1 In the process of assembling the various components: first place the micropores of the composite special-shaped spinneret downward on the special assembly frame, put the fine side of the filter screen 2 upward into the upper groove of the spinneret 1, and then align the screw holes to cover the housing 3 , The threaded part of the hexagonal bolt is coated with a small amount of high-temperature resistant silicone grease, and the bolt is fixed symmetrically with a certain force. Finally, a gasket 4 is inlaid at the entrance of the shell melt, and the gasket 4 is an annular aluminum gasket.

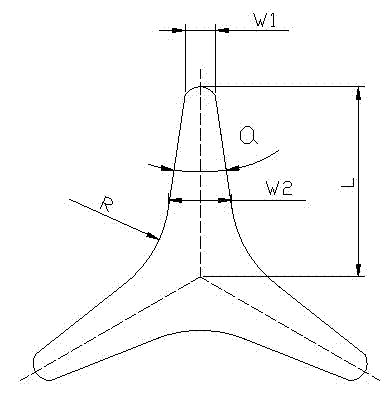

[0018] The innovation point of the present invention is the improvement of spinneret hole, as figure 2 As shown, the spinneret hole is a compound special-shaped structure of trilobal (Y) shape and triangular (△) shape, that is, on the basis of the original trilobal shape, the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ye chang | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Ye chang | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com