Nutritious ice cream powder and its production process

A technology of ice cream powder and production process, applied in the field of ice cream, can solve the problems of obesity, increased blood sugar, increased load of islet cells, etc., and achieve the effects of prolonging shelf life, rich aroma and high degree of flavor retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

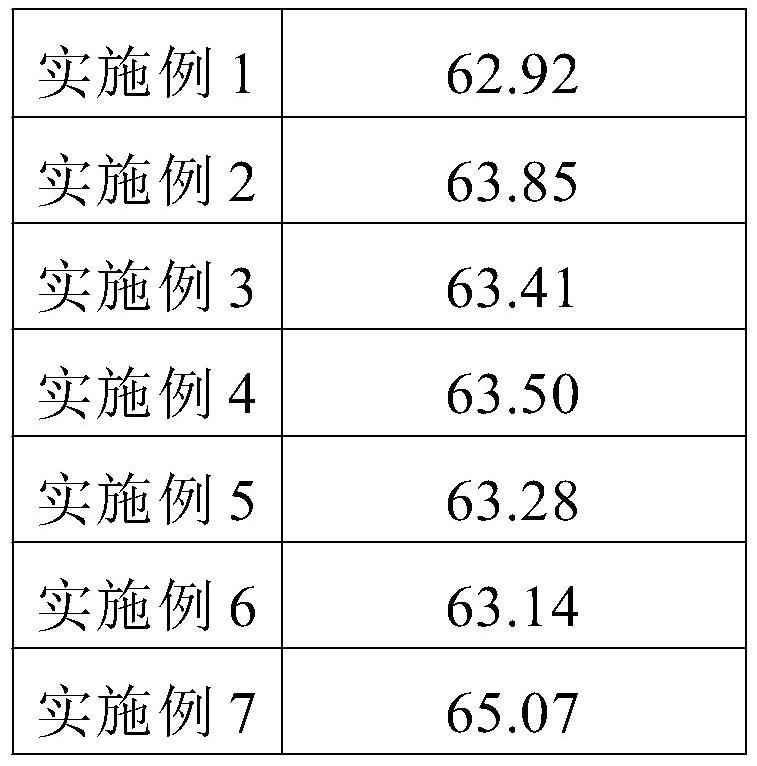

Embodiment 1

[0044] The production technology of nutritious ice cream powder comprises the following steps:

[0045] S1. Weigh each raw material by weight: 30 parts by weight of skimmed milk powder, 1 part by weight of L-arabinose, 4 parts by weight of xylitol, 10 parts by weight of white sugar, 25 parts by weight of whey protein powder, 3 parts by weight of egg yolk powder , 0.1 parts by weight of chitosan quaternary ammonium salt, 0.45 parts by weight of guar gum, 0.35 parts by weight of clove oleoresin, 2.5 parts by weight of maltodextrin;

[0046]S2. Mix the above-mentioned raw materials evenly, and perform ultra-high pressure sterilization. The ultra-high pressure sterilization is to keep the pressure at a pressure of 400 MPa for 15 minutes; to obtain nutritious ice cream powder.

[0047] The preparation process of the clove oleoresin is as follows: crush male cloves through a 80-mesh sieve to obtain male clove powder; mix the male clove powder and ethanol aqueous solution with a mass...

Embodiment 2

[0049] The production technology of nutritious ice cream powder comprises the following steps:

[0050] S1. Weigh each raw material by weight: 30 parts by weight of skimmed milk powder, 1 part by weight of L-arabinose, 4 parts by weight of xylitol, 10 parts by weight of white sugar, 25 parts by weight of whey protein powder, 3 parts by weight of egg yolk powder , 0.1 parts by weight of chitosan quaternary ammonium salt, 0.45 parts by weight of guar gum, 0.35 parts by weight of microencapsulated clove oleoresin, 2.5 parts by weight of maltodextrin;

[0051] S2. Mix the above-mentioned raw materials evenly, and perform ultra-high pressure sterilization. The ultra-high pressure sterilization is to keep the pressure at a pressure of 400 MPa for 15 minutes; to obtain nutritious ice cream powder.

[0052] The preparation process of the microencapsulated clove oleoresin is as follows: crush male cloves through an 80-mesh sieve to obtain male clove powder; mix male clove powder and et...

Embodiment 3

[0054] The production technology of nutritious ice cream powder comprises the following steps:

[0055] S1. Weigh each raw material by weight: 30 parts by weight of skimmed milk powder, 0.5 parts by weight of L-arabinose, 2 parts by weight of xylitol, 10 parts by weight of white sugar, 25 parts by weight of whey protein powder, 3 parts by weight of egg yolk powder , 0.1 parts by weight of chitosan quaternary ammonium salt, 0.45 parts by weight of guar gum, 0.35 parts by weight of microencapsulated clove oleoresin, 2.5 parts by weight of maltodextrin;

[0056] S2. Mix the above-mentioned raw materials evenly, and perform ultra-high pressure sterilization. The ultra-high pressure sterilization is to keep the pressure at a pressure of 400 MPa for 15 minutes; to obtain nutritious ice cream powder.

[0057] The preparation process of the microencapsulated clove oleoresin is as follows: crush male cloves through an 80-mesh sieve to obtain male clove powder; mix male clove powder and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com