Bubble shelled melon seeds and production method thereof

A production method and the technology of melon seeds, which are applied in the field of bubble melon seeds and their production, can solve the problems of affecting the absorption and utilization of vitamins, reducing the nutritional value of food, and affecting the digestion and absorption of food, so as to achieve a soft and smooth taste and improve the mouthfeel , the effect of novel taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

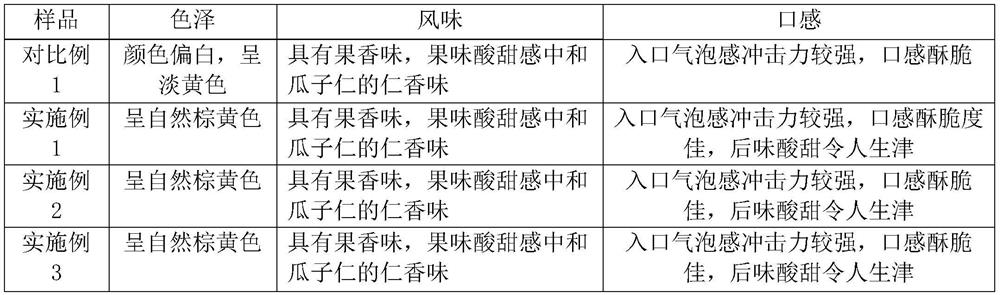

Examples

Embodiment 1

[0044] A kind of production method of bubble melon seeds, comprises the following steps:

[0045] S1. Weigh the mixed powder and sugar water according to the mass ratio of 1:0.8; the preparation method of the sugar water is: white granulated sugar and water are mixed according to the mass ratio of 1:0.6;

[0046] The mixed powder comprises the following mass parts raw materials: 30 parts of resistant dextrin, 20 parts of cornstarch, 50 parts of modified starch, 0.1 part of composite leavening agent; described composite leavening agent is made up of baking soda and ammonium bicarbonate, wherein The mass ratio of baking soda to ammonium bicarbonate is 1:0.5;

[0047] S2. The raw material of melon seeds is oil sunflower kernels, the ratio of melon seeds to mixed powder is 1:1; put 100kg of melon seeds into the wrapping machine, turn on the machine, sprinkle 8kg of sugar water and stir for 3 minutes under stirring conditions, so that the surface of melon seeds Wet, then add 10kg ...

Embodiment 2

[0056] A kind of production method of bubble melon seeds, comprises the following steps:

[0057] S1. Weigh the mixed powder and sugar water according to the mass ratio of 1:0.7; the preparation method of the sugar water is: white granulated sugar and water are mixed according to the mass ratio of 1:0.7;

[0058] The mixed powder comprises the following mass parts raw materials: 40 parts of resistant dextrin, 30 parts of cornstarch, 30 parts of modified starch, 0.3 part of composite leavening agent; the composite leavening agent is made up of baking soda and ammonium bicarbonate, wherein The mass ratio of baking soda to ammonium bicarbonate is 1:0.3;

[0059] S2. Sunflower kernels are selected as the raw material of melon seeds. The ratio of melon seeds to mixed powder is 1:0.9. Put 100Kg of melon seeds into a wrapping machine, add 10kg of sugar water to wet the surface, and stir for 2 minutes to make the surface of melon seeds moist. Wet, then add 14kg of mixed powder, stir,...

Embodiment 3

[0068] A kind of production method of bubble melon seeds, comprises the following steps:

[0069] S1. Weigh the mixed powder and sugar water according to the mass ratio of 1:0.6; the preparation method of the sugar water is: white granulated sugar and water are mixed according to the mass ratio of 1:0.8;

[0070] Described mixing powder comprises following mass parts raw material: 50 parts of resistant dextrins, 10 parts of cornstarch, 40 parts of modified starches, 0.5 part of composite leavening agent; Described composite leavening agent is made up of baking soda and ammonium bicarbonate, wherein The mass ratio of baking soda to ammonium bicarbonate is 1:0.2.

[0071] S2. The raw material of melon seeds is oil sunflower kernels. The ratio of melon seeds to mixed powder is 1:0.8. Put 100Kg of melon seeds into the wrapping machine, turn on the machine, sprinkle 5kg of sugar water under stirring conditions, stir for 3 minutes, and moisten the melon seeds. Then add 8kg of mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com