High water-absorption, high moisture-absorption, super-flexible blended tended tender twisted yarn and its production process

A technology of highly hygroscopic, weakly twisted yarn, applied in the direction of yarn, textile and papermaking, can solve the problems of poor loop shape retention, easy hairiness, etc., and achieve the effect of good economy, good elasticity, and improved quality performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The high water absorption, high moisture absorption, supersoft blended weak twist yarn of the present invention comprises high moisture absorption polyester and cotton fibers blended into single yarns, and the blended high moisture absorption polyester and cotton fibers are combined with water-soluble yarns and twisted. Wherein: the weight ratio of high moisture absorption polyester, cotton fiber and water-soluble yarn is 1:5-6:2-3. The water-soluble yarn is water-soluble vinylon staple fiber. Cotton fiber adopts high-quality long-staple cotton or high-quality commonly used cotton. When the cotton and polyester blended yarn is combined and twisted with water-soluble yarn, the twist direction is opposite to that of the single yarn, and the twist of the ply is smaller than that of the blended single yarn.

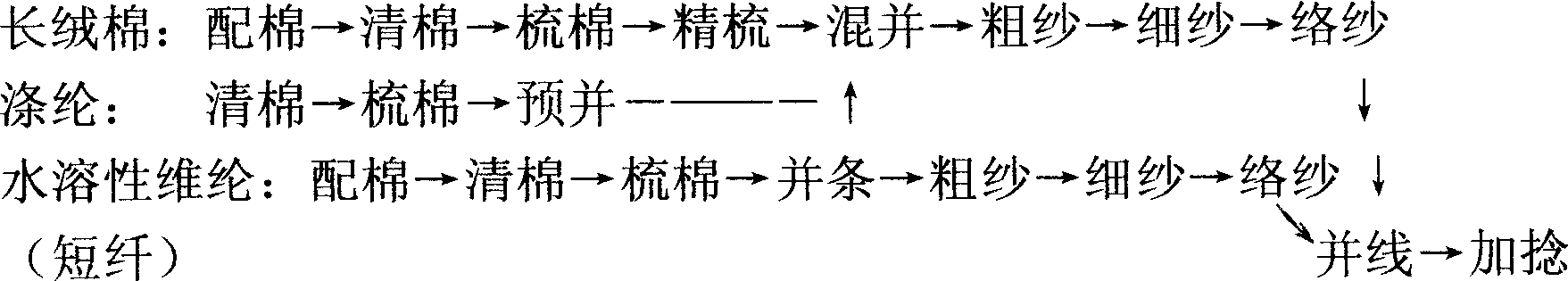

[0013] Routing:

[0014]

Embodiment 2

[0016] The high water absorption, high moisture absorption, supersoft blended weak twist yarn of the present invention comprises high moisture absorption polyester and cotton fibers blended into single yarns, and the blended high moisture absorption polyester and cotton fibers are combined with water-soluble yarns and twisted. Wherein: the weight ratio of high moisture absorption polyester, cotton fiber and water-soluble yarn is 1:5-6:1-2. The water-soluble yarn adopts water-soluble vinylon filament. Cotton fiber adopts high-quality long-staple cotton or high-quality commonly used cotton. When the cotton and polyester blended yarn is combined and twisted with water-soluble yarn, the twist direction is opposite to that of the single yarn, and the twist of the ply is smaller than that of the blended single yarn.

[0017] Routing:

[0018] Long-staple cotton: blending→cleaning→carding→combing→blending→roving→spinning→winding

Embodiment 3

[0022] The high water absorption, high moisture absorption and supersoft blended weak twist yarn of the present invention comprises high moisture absorption polyester and cotton fibers blended into single yarns, and the blended high moisture absorption polyester and cotton fibers are combined with water-soluble yarns, wherein: high The weight ratio of the hygroscopic polyester, cotton fiber and water-soluble yarn is 1:5-6:1-2. The water-soluble yarn adopts water-soluble vinylon filament. Cotton fibers are made of high-quality long-staple cotton or

[0023] High quality commonly used cotton. Cotton and polyester blended yarn and water-soluble yarn are combined by spinning frame.

[0024] Routing:

[0025] Long-staple cotton: blending→cleaning→carding→combing→blending→roving→spinning→winding

[0026] Polyester: Cleaning → Carding → Pre-combination ————— ↑ ↑

[0027] Water-soluble vinylon filament: ———————————————————↓

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com