Ultra-strong antistatic spandex spinning oil and preparation method thereof

A spinning oil, antistatic technology, applied in the field of new oil, can solve problems such as unfavorable implementation, poor antistatic performance, complex process, etc., and achieve good dispersion stability, super antistatic performance, and excellent unwinding properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

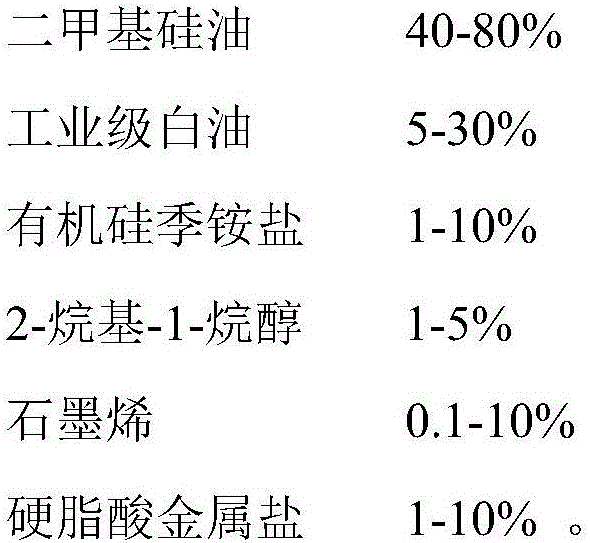

Method used

Image

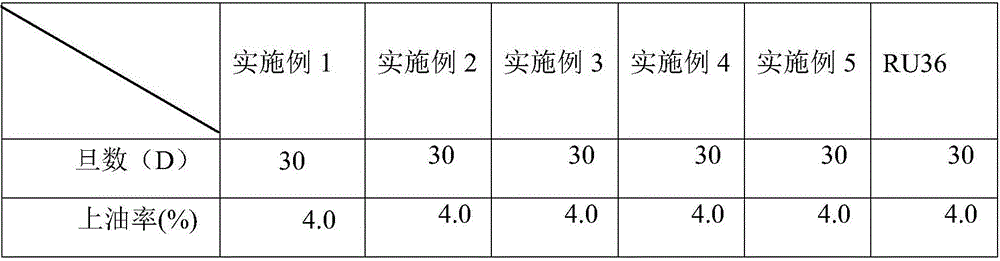

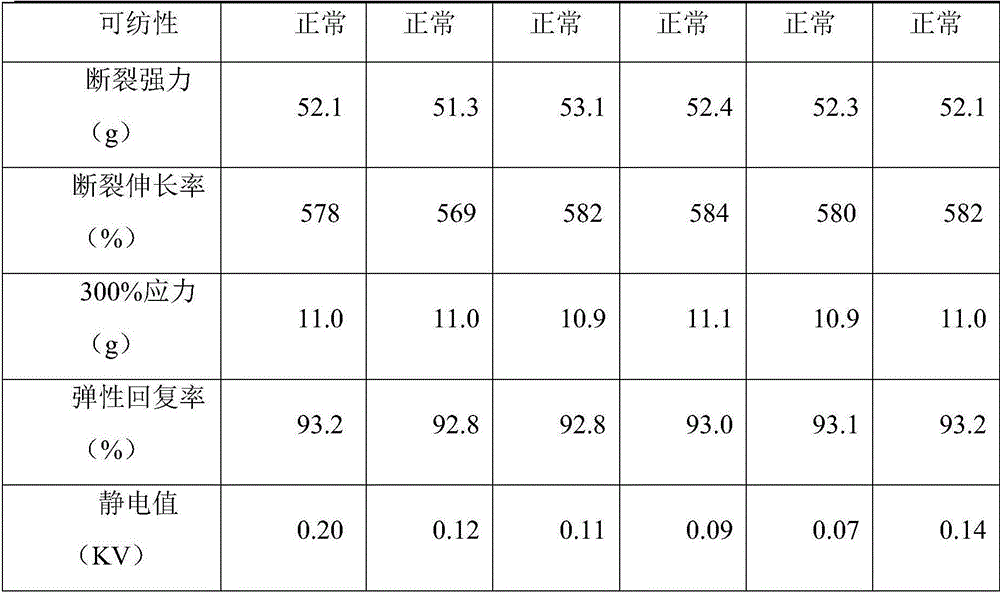

Examples

Embodiment 1

[0021] Add 72% by weight of simethicone oil (the kinematic viscosity at 25 degrees Celsius is 10mPa.s), 15% by weight of industrial white oil to a high-speed mechanical stirring and dispersing device and stir for 1h to obtain a colorless and transparent component, and then Add 5% by weight of organosilicon quaternary ammonium salt, 3% by weight of 2-alkyl-1-alkanol, and 5% by weight of magnesium stearate in the device, at a temperature of 50°C at 100r / min After stirring for 0.5 hours at a rotating speed, the spandex dry spinning oil was obtained by acoustically dispersing for 1 hour.

[0022] The main performance of the oil agent:

[0023] Appearance: colorless and transparent

[0024] Viscosity: 10.6mPa.s

[0025] Density: 0.882mg / cm 3

[0026] PH value: 6-7

[0027] Volatile matter: 0.35% (100°C, 1h).

Embodiment 2

[0029] Add 70% by weight of simethicone oil (the kinematic viscosity at 25 degrees Celsius is 10mPa.s), 15% by weight of industrial white oil to a high-speed mechanical stirring and dispersing device and stir for 1h to obtain a colorless and transparent component, and then Add 5% by weight of organic silicon quaternary ammonium salt, 3% by weight of 2-alkyl-1-alkanol, 2% by weight of graphene oxide, 5% by weight of magnesium stearate in the device, at 50 Stir at 100r / min for 0.5h at a temperature of °C and then acoustically disperse for 1 hour to obtain the spandex dry spinning finish.

[0030] The main performance of the oil agent:

[0031] Appearance: colorless and transparent

[0032] Viscosity: 11.0mPa.s

[0033] Density: 0.890mg / cm 3

[0034] PH value: 6-7

[0035] Volatile matter: 0.34% (100°C, 1h).

Embodiment 3

[0037] Add 68% by weight of simethicone oil (the kinematic viscosity at 25 degrees Celsius is 10mPa.s), 15% by weight of industrial white oil to a high-speed mechanical stirring and dispersing device and stir for 1h to obtain a colorless and transparent component, and then Add 5% by weight of organic silicon quaternary ammonium salt, 3% by weight of 2-alkyl-1-alkanol, 4% by weight of graphene oxide, 5% by weight of magnesium stearate in the device, at 50 Stir at 100r / min for 0.5h at a temperature of °C and then acoustically disperse for 1 hour to obtain the spandex dry spinning finish.

[0038] The main performance of the oil agent:

[0039] Appearance: colorless and transparent

[0040] Viscosity: 11.1mPa.s

[0041] Density: 0.892mg / cm 3

[0042] PH value: 6-7

[0043] Volatile matter: 0.34% (100°C, 1h)

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com