Active openings agent, reticulated urethane foam material and preparation methods for active openings agent and reticulated urethane foam material

A polyurethane foam and cell opener technology, applied in the chemical industry, can solve the problems of poor product quality, potential safety hazards, uneven cells, etc., and achieve improved operating latitude, no potential safety hazards, and uniform cells. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

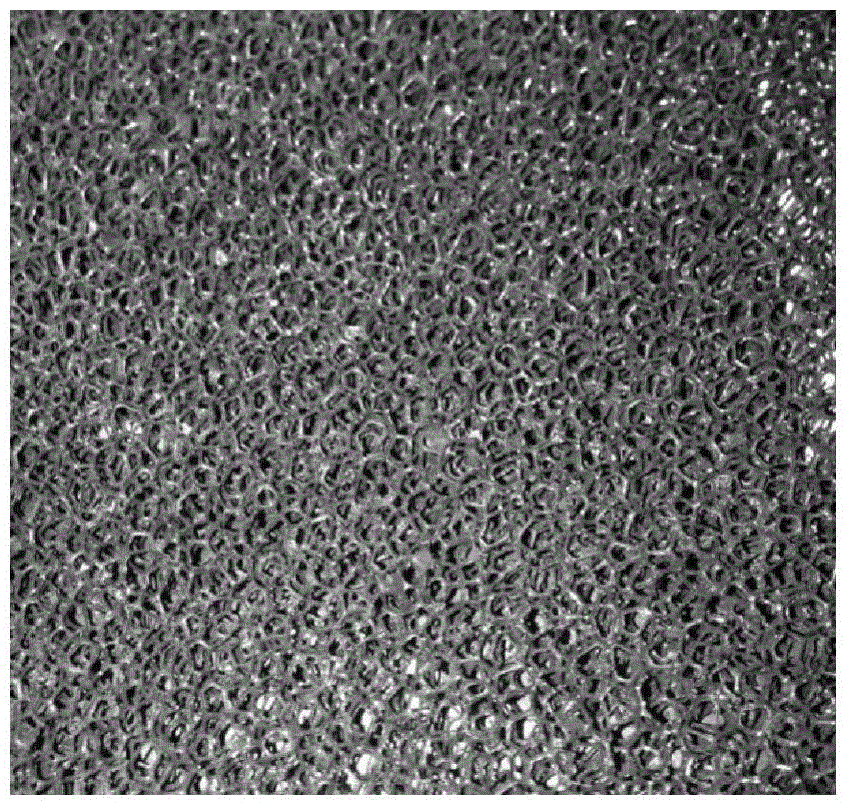

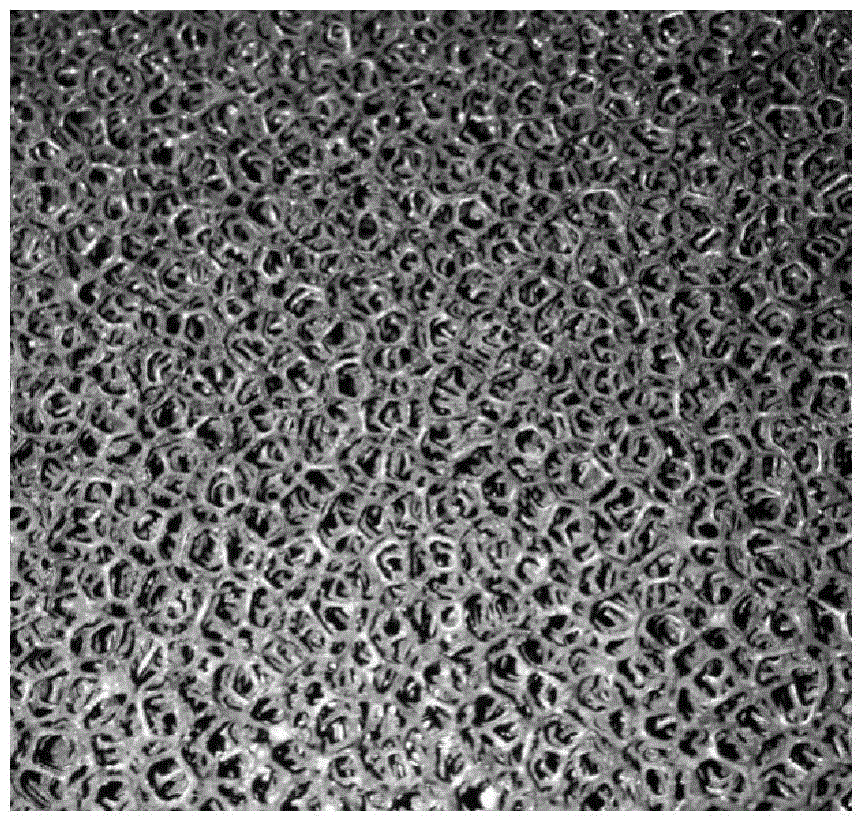

Image

Examples

Embodiment 1

[0043] The first step: the active cell opener component (1) - the preparation of the diol or polyol of the oxyalkylene ether with 2 or more primary hydroxyl structures reacted with the first acid anhydride

[0044] In a 500ml four-necked flask with a fixed device, a constant temperature function, a mechanical stirrer, a thermocouple, a vacuum device and nitrogen gas, add 250g of n-butanol starting weight average molecular weight of 1500 oxirane groups and The weight percentage of propylene oxide group is 1 / 1 polyoxyalkylene ether alcohol, then add 50 grams of acetic anhydride, use nitrogen protection, start stirring, use a heating mantle to heat to 120 ° C, stir for 8 hours, add 200 ppm of polyether Refining the adsorbent, reacting for 1 hour, cooling to 35-50 degrees and filtering to obtain a clear and transparent light yellow liquid. This product is referred to herein as active cell opener component (1).

[0045] The second step: compounding of active cell opening agent

...

Embodiment 2

[0048] The first step: the active cell opener component (1) - the preparation of the diol or polyol of the oxyalkylene ether with 2 or more primary hydroxyl structures reacted with the first acid anhydride

[0049] In a 500ml four-necked flask with a fixed device, a constant temperature function, a mechanical stirrer, a thermocouple, a vacuum device and nitrogen gas, add 250g of allyl alcohol starting weight average molecular weight of 3000 oxirane groups and The weight percentage of propylene oxide group is 1 / 1 polyoxyalkylene ether alcohol, then add 30 grams of acetic anhydride, use nitrogen protection, start stirring, use a heating mantle to heat to 120 ° C, stir for 8 hours, add 200 ppm of polyether Refining the adsorbent, reacting for 1 hour, cooling to 35-50 degrees and filtering to obtain a clear and transparent light yellow liquid. This product is referred to herein as active cell opener component (1).

[0050] The second step: compounding of active cell opening agent...

Embodiment 3

[0052] Embodiment 3 prepares reticulated polyurethane flexible foam:

[0053] Adopt above-mentioned embodiment 1, embodiment 2, select for use to add the prescription of activating agent cell opener as comparative example 1, implement the reticular polyurethane flexible foam that 2 prepares, select foam density as 24kg / m 3 The formula, the result is as following table 1:

[0054] According to the formula in Table 1, weigh the required polyether polyol V-3010, deionized water, amine catalyst Dabco*33LV, silicone surfactant BL-580NA, and dichloromethane. Then the mixture was stirred at 1500 revolutions per minute for 2 hours, and then the mixture was stored in a storage tank with a temperature-controlled water bath, and slowly stirred until the temperature of the polyether composite material was controlled at 21 degrees.

[0055] According to the formula in Table 1, in a container with a capacity of about 100L, the polyether combination material, activator cell opener, and stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com