Method for preparing defoamer for cement mortar containing rubber emulsion

A technology of silicone defoamer and precipitation method, which is applied in the field of anti-corrosion and waterproofing of buildings, can solve the problems of slow defoaming and unsatisfactory defoaming, reduce the amount of bubbles produced, increase the speed of defoaming, and strengthen the defoaming and breaking The effect of bubble ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] The descriptions and diagrams below are exemplary embodiments of the present invention, but are not limited to these several variants.

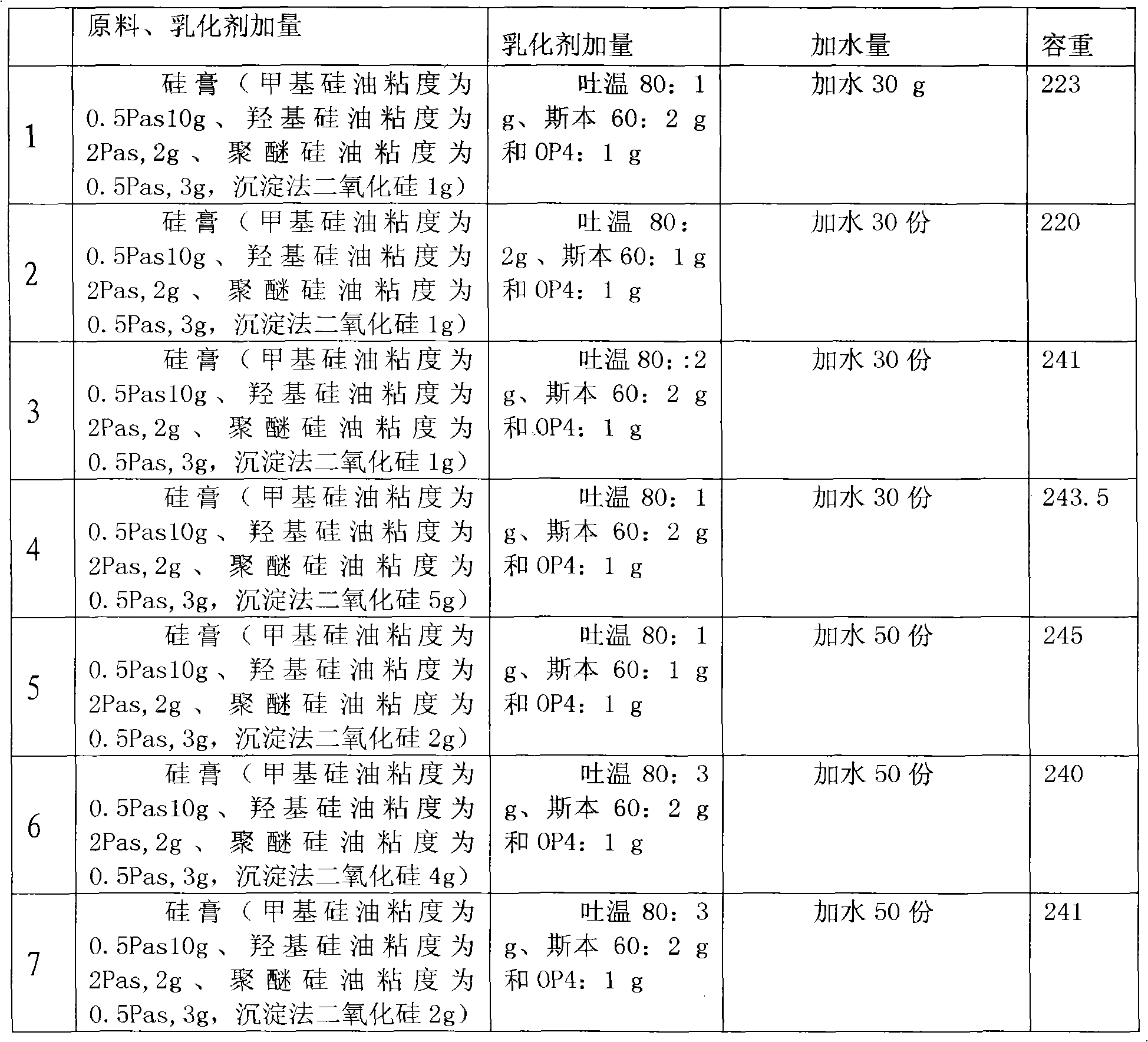

[0006] The first part is to make silicone paste, that is, the main raw material composition includes dimethyl silicone oil, hydroxyl silicone oil, polyether silicone oil, and precipitated silica. The above parts by weight are 10 parts, 2 parts, 3 parts, 1-5 When configuring, three kinds of silicone oils and precipitated silica are made into silicone paste at 140-200°C through a three-roll mill. The second part is to add silicone paste and emulsifier (Tween 80: 1-3 parts, Siben 60: 1-3 parts and OP4: 1 part) in the stirring tank, at a temperature of 80 ° C, add 30-50 parts of water while stirring , Stir evenly for half an hour to make a uniform emulsion, which is the silicone defoamer. Among them, the viscosity of methyl silicone oil is 0.5-1 Pas, the viscosity of hydroxy silicone oil is 2-3 Pas, and the viscosity of polyether silicone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com