Gas turbine guide flow disk

A gas turbine and deflector technology, applied in the field of turbines, can solve the problems of increasing the burden on the turbine disk, shifting the center of gravity of the structure to the right, and reducing the rupture speed, etc., so as to reduce the centrifugal load, meet the design requirements, and reduce the stress level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

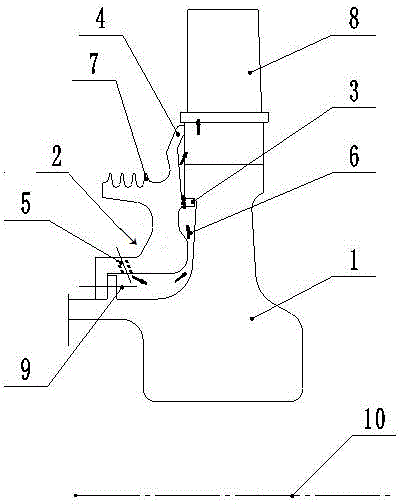

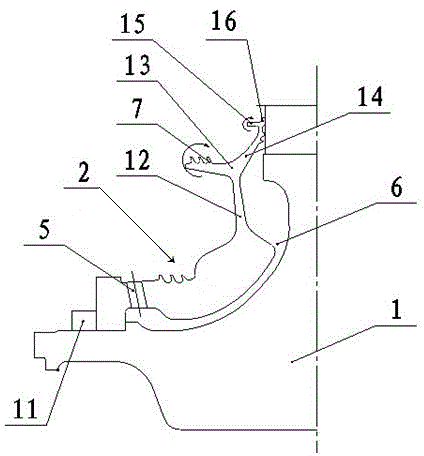

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0028] Such as figure 2 As shown, the present invention provides a gas turbine deflector plate 2, which includes a connecting end, an intermediate section 12 and a sealing end connected in sequence, and the intermediate section 12 connects the connecting end and the sealing end; The position of the middle section is divided into the seal 4 and the tooth end 7 to both sides respectively, and the starting position of the differentiation to both sides is the bifurcation 13;

[0029] The middle section 12 is a flexible thin plate whose thickness gradually decreases from both ends to the middle, so that the part above the middle section 12 is prone to rotate around the center of the bifurcation 13 under the action of centrifugal force;

[0030] The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com