Electromagnetic-repulsion-driven high-speed piston type interrupter

A technology of driving piston and electromagnetic repulsion, applied to the power device inside the switch and other directions, can solve the problems of harsh environmental temperature requirements, large overall volume, poor economy, etc., to improve the breaking speed and reliability, broad engineering application prospects, meet the Effect of temperature rise requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

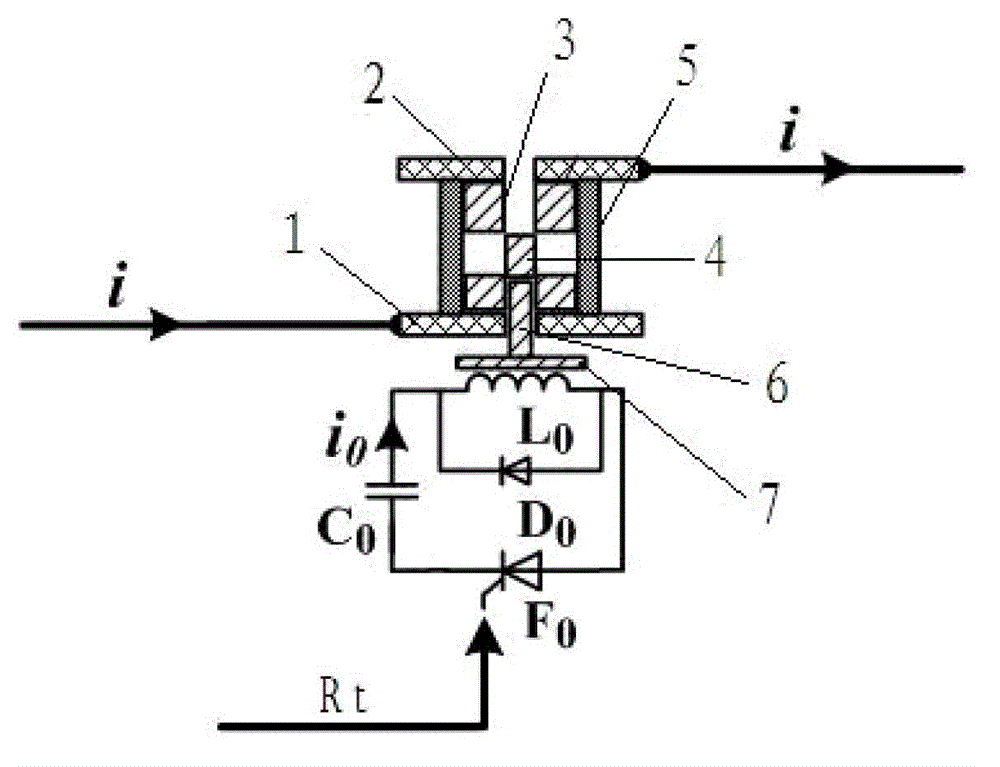

[0023] Such as figure 1 As shown, the present invention includes a repulsion drive circuit and a repulsion coil L connected in the repulsion drive circuit 0 . The repulsion drive circuit includes a capacitor C connected in series with a pre-charged voltage 0 , Thyristor F 0 and freewheeling diode D 0 , capacitor C 0 The positive and negative poles are respectively connected to the freewheeling diode D 0 Negative pole, thyristor F 0 Cathode connection, freewheeling diode D 0 Anode and thyristor F 0 anode connection, the repulsion coil is connected in series with the capacitor C 0 with thyristor F 0 between and with the freewheeling diode D 0 Parallel, Thyristor F 0 It turns on after receiving the trigger signal Rt from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com