a power cabinet

A technology for power cabinets and power components, applied in the field of power cabinets, can solve problems such as easy failure, fault expansion, arc short circuit, etc., and achieve the effects of improving detection accuracy, enhancing interchangeability, and reducing operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

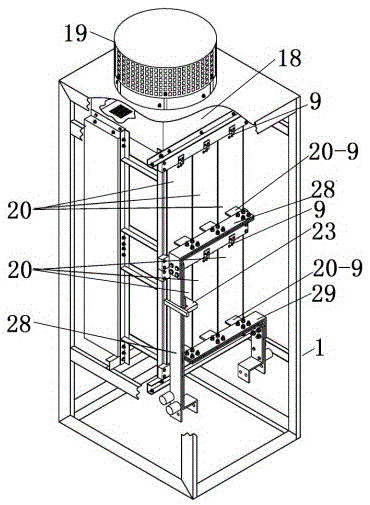

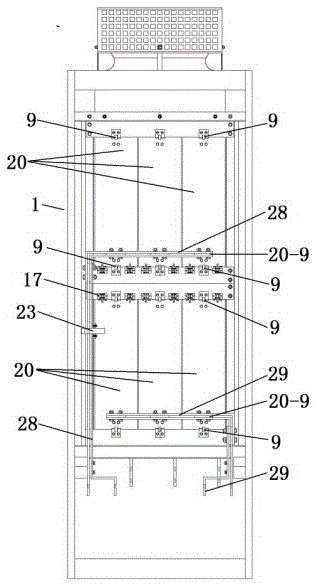

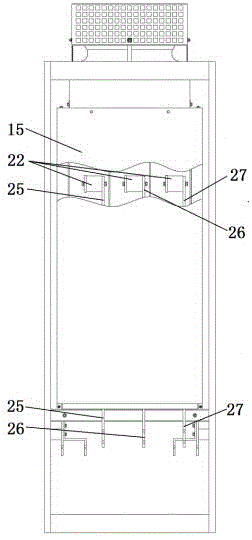

[0021] Such as Figure 1 to Figure 11 As shown, a power cabinet includes a cabinet 1 composed of a left side panel, a right side panel, a front door, a rear door, and an upper wind bucket 18 fixed on the frame, and also includes a power assembly 20, a fast fuse 22, and a current Hall sensor 23 , Current transformer 24, AC bus bar 1W125, AC bus bar 1V126, AC bus bar 1U127, DC bus bar 1C128, DC bus bar 1D129.

[0022] Power assembly 20, including radiator I20-1, radiator II20-2, radiator III20-3, front windshield 20-4, rear windshield 20-5, guide groove 20-6, connecting row 20-7 , AC side lead-out row 20-8, DC side lead-out row 20-9, thyristor 20-10, resistor 20-12, capacitor 20-13, also includes inner air duct plate 20-11, inner air duct plate 20-11 consists of Set as one vertical plate 20-11-1, upper horizontal plate 20-11-2 and lower horizontal plate 20-11-3 to form three.

[0023] Several ventilation holes 20-11-23 are symmetrically arranged on the upper horizontal plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com