High-slump-loss-resistant synergist and preparation method and application thereof

A technology of synergist and retaining agent, which is applied in the field of high slump-preserving synergist and its preparation, can solve the problems of fast slump loss of concrete, solve the problem of fast slump loss, reduce the loss over time, and save the cost of concrete Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

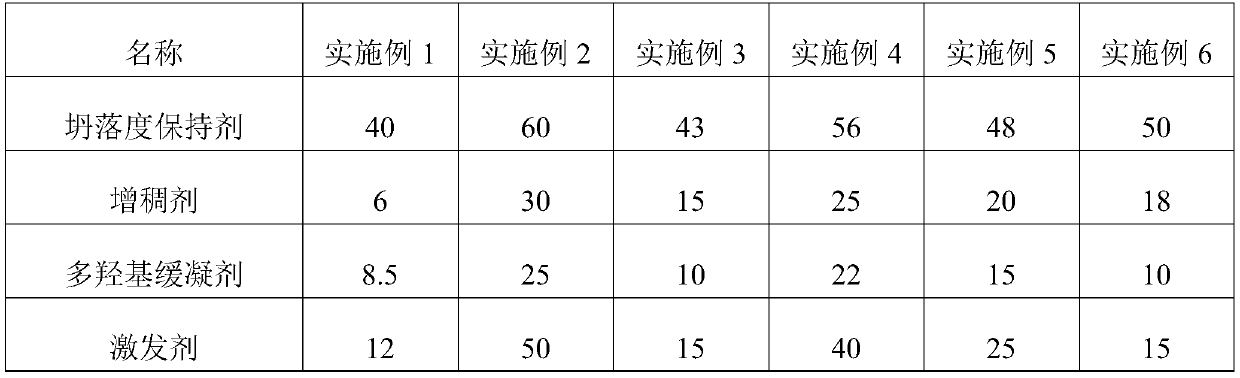

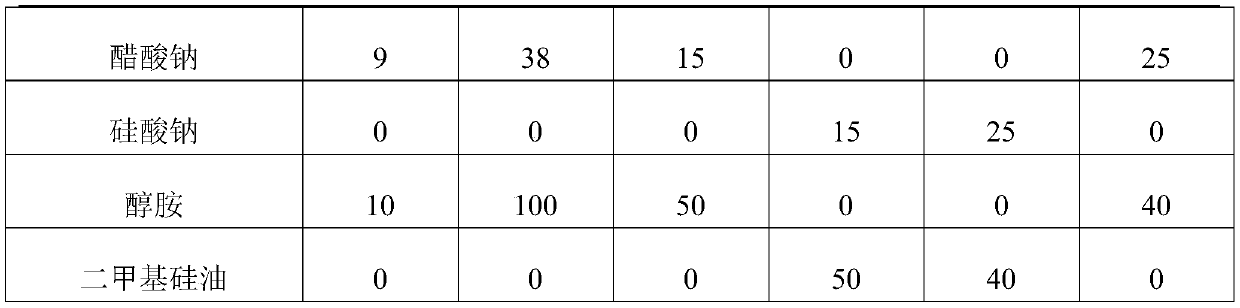

Embodiment 1

[0035] A high slump retention synergist, consisting of the following components by weight:

[0036] 40 parts of slump retaining agent, 6 parts of β-cyclodextrin, 8.5 parts of polyhydroxy retarder, 12 parts of sodium thiocyanate, 9 parts of sodium acetate, 10 parts of alcohol amine,

[0037] Described slump retaining agent is made up of the following components by weight:

[0038] 180 parts of methallyl alcohol polyoxyethylene ether, 120 parts of isoamyl alcohol polyoxyethylene ether, 20 parts of unsaturated acid, 30 parts of hydroxypropyl acrylate, 1.1 part of thioglycolic acid, 0.5 part of vitamin C,

[0039] Its preparation method comprises the following steps:

[0040] S1, material preparation: according to the above formula, weigh each component for subsequent use;

[0041] S2. Prepare materials A and B: dissolve thioglycolic acid and vitamin C in water to obtain material A, dissolve unsaturated acid and hydroxypropyl acrylate in water to obtain material B, and set aside...

Embodiment 2

[0046] A high slump retention synergist, consisting of the following components by weight:

[0047] 60 parts of slump retaining agent, 30 parts of dispersible latex powder, 25 parts of polyhydric retarder, 50 parts of sodium thiocyanate, 38 parts of sodium acetate, 100 parts of alcohol amine,

[0048] Described slump retaining agent is made up of the following components by weight:

[0049] 300 parts of methallyl alcohol polyoxyethylene ether, 150 parts of isoamyl alcohol polyoxyethylene ether, 45 parts of unsaturated acid, 80 parts of ethyl methacrylate, 3.8 parts of mercaptoethanol, 1.5 parts of vitamin C,

[0050] Its preparation method comprises the following steps:

[0051] S1, material preparation: according to the above formula, weigh each component for subsequent use;

[0052] S2. Prepare materials A and B: dissolve mercaptoethanol and vitamin C in water to obtain material A, dissolve unsaturated acid and ethyl methacrylate in water to obtain material B, and set asid...

Embodiment 3

[0057] A high slump retention synergist, consisting of the following components by weight:

[0058] 43 parts of slump retaining agent, 15 parts of cellulose, 10 parts of polyhydroxy set retarder, 15 parts of sodium glucose, 10 parts of sodium acetate, 50 parts of alcohol amine,

[0059] Described slump retaining agent is made up of the following components by weight:

[0060] 150 parts of allyl polyoxyethylene ether, 200 parts of isobutenyl polyvinyl ether, 25 parts of unsaturated acid, 20 parts of hydroxypropyl acrylate, 20 parts of ethyl methacrylate, 1.5 parts of dodecyl mercaptan, vitamin C 0.7 parts,

[0061] Its preparation method comprises the following steps:

[0062] S1, material preparation: according to the above formula, weigh each component for subsequent use;

[0063] S2. Prepare materials A and B: dissolve lauryl mercaptan and vitamin C in water to obtain material A, dissolve unsaturated acid, butyl acrylate, and ethyl methacrylate in water to obtain material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com