Method for control of NOX emissions from combustors using fuel dilution

a technology of nox emissions and combustors, which is applied in the direction of continuous combustion chambers, climate sustainability, machines/engines, etc., can solve the problems of flame blowout or extinction, flame blowout lines shifting to lower temperatures, etc., and achieves the effect of faster chemical reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

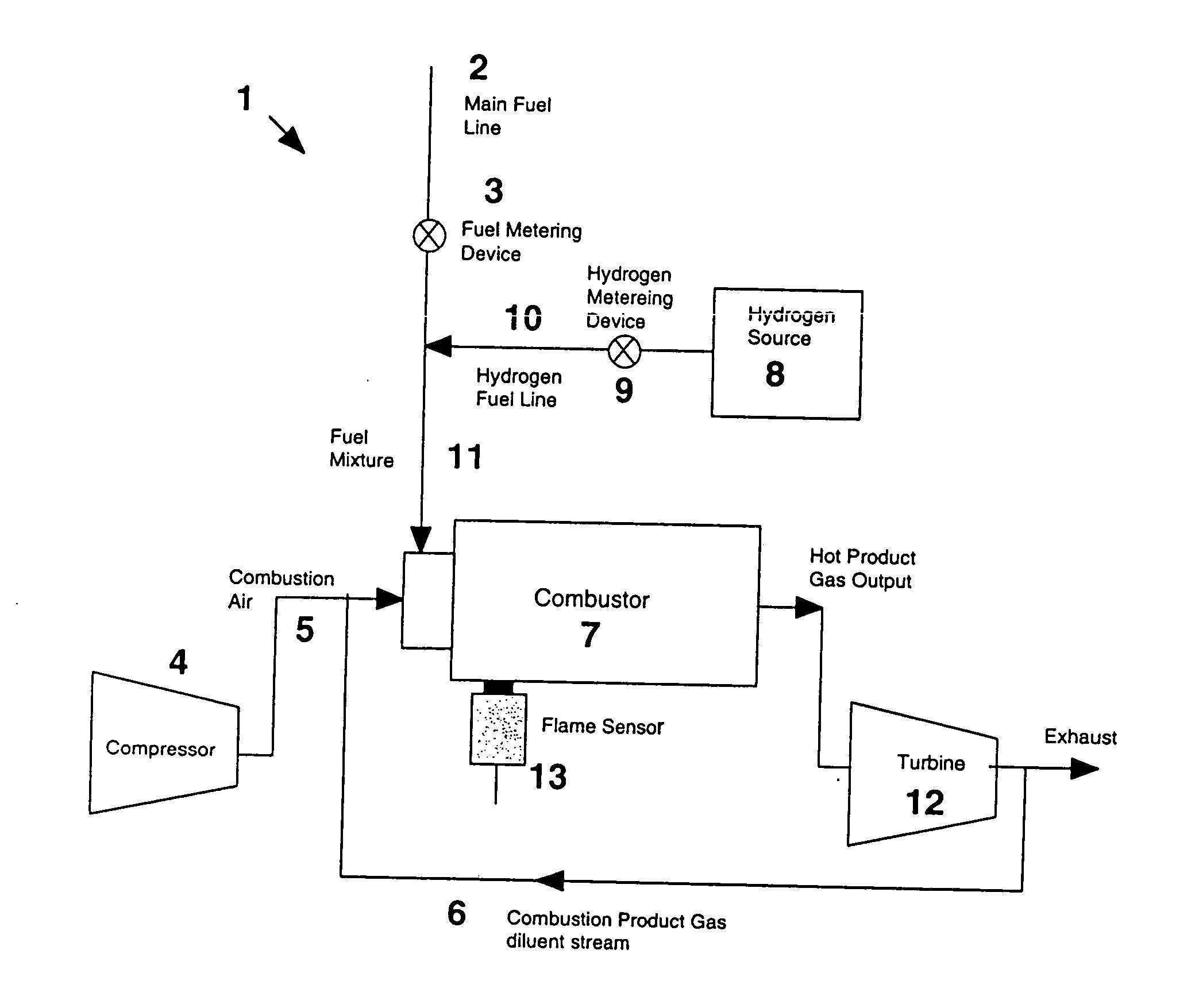

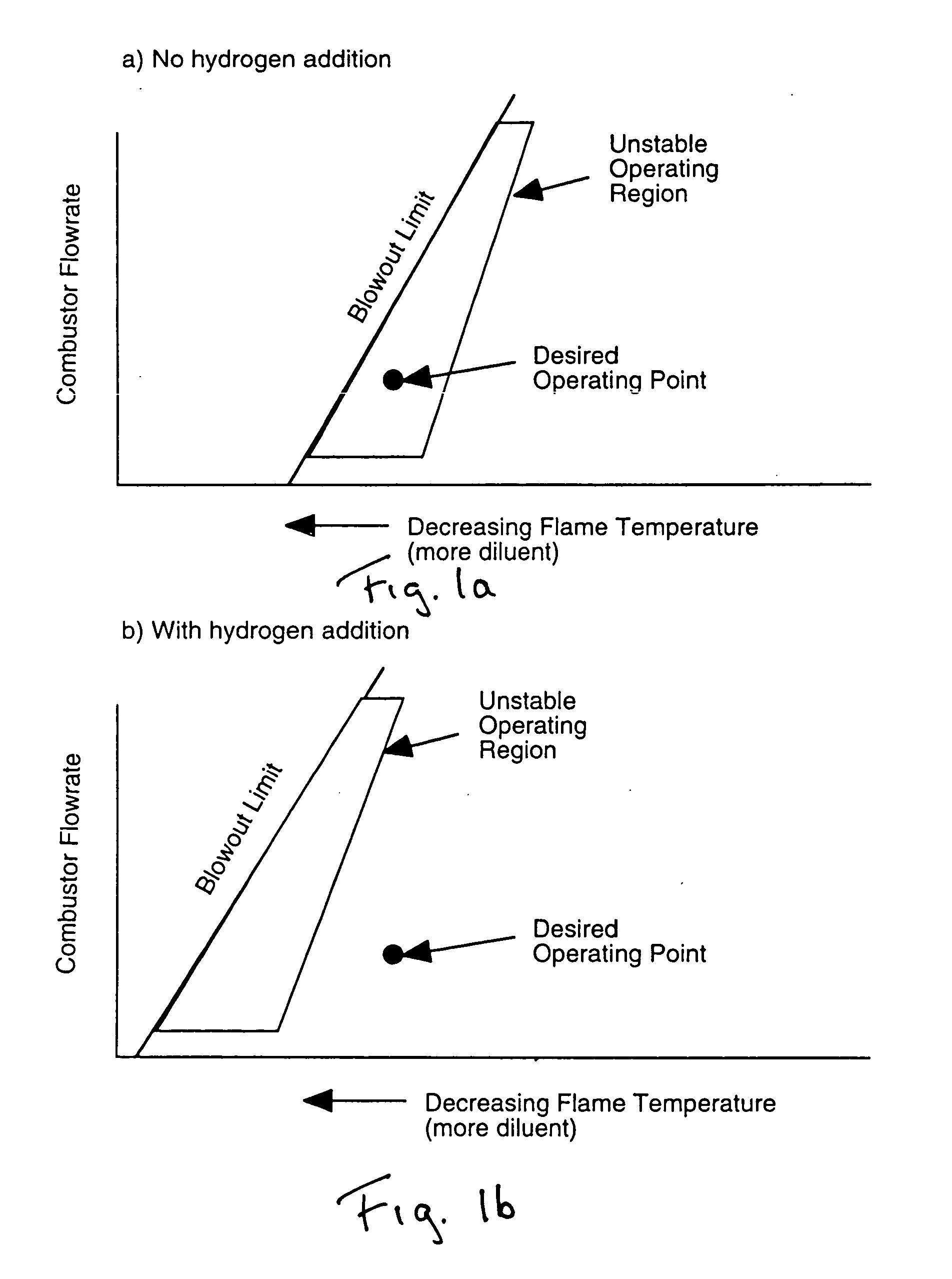

[0017] The invention is directed to a method of controlling NOx emission from combustors. The method comprises, generally, providing a inlet fuel mixture to a combustor, wherein the inlet fuel mixture comprises a base hydrocarbon fuel that can be a natural gas, methane, coal gas, biomass-derived fuel or other hydrocarbon fuel materials, a diluent gas, such as water vapor, nitrogen, or combustion product gas, and a gas capable of promoting flame stability and improve low temperature combustion characteristics, such as hydrogen.

[0018] The notation “NOx” as used herein represents all nitrogen oxides. The value of “x” can be at least one and can have non-integer values.

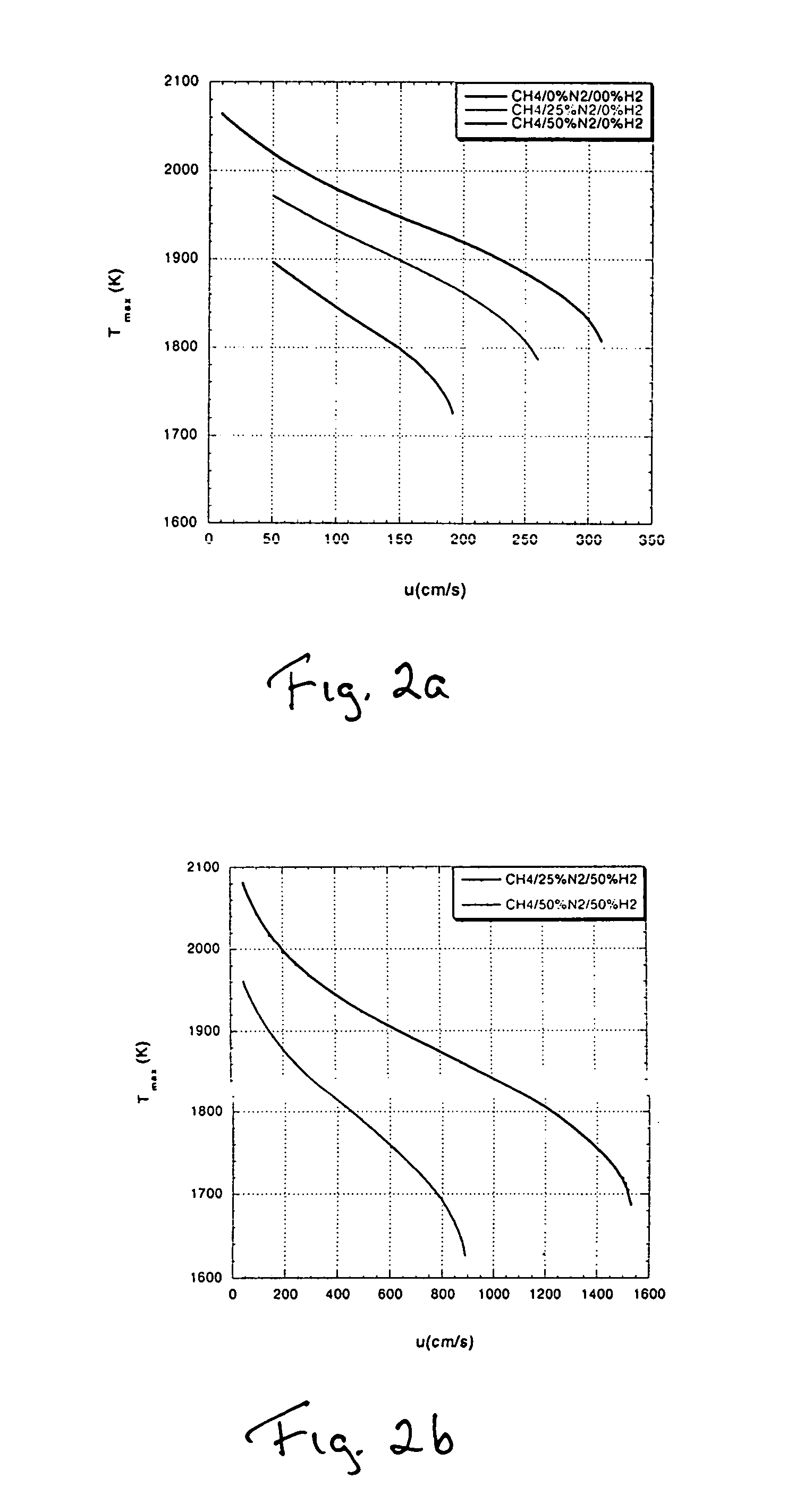

[0019] In order to demonstrate the efficacy of the invention, calculations were undertaken to demonstrate reduction in NOx emissions with diluent gas and flame stability gas additions to the inlet gas (CH4). In the cases illustrated here, the diluent gas was N2 and the gas used to provide flame stability was H2.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com