Combustion system and method for self adaption controllable heat premixing direct jet type diesel engine

An adaptive combustion system technology, applied in the direction of charging system, combustion engine, mechanical equipment, etc., can solve problems such as difficult to control the combustion rate, and achieve the effects of improving combustion efficiency, reducing flame temperature, and reducing soot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention are as shown in the accompanying drawings:

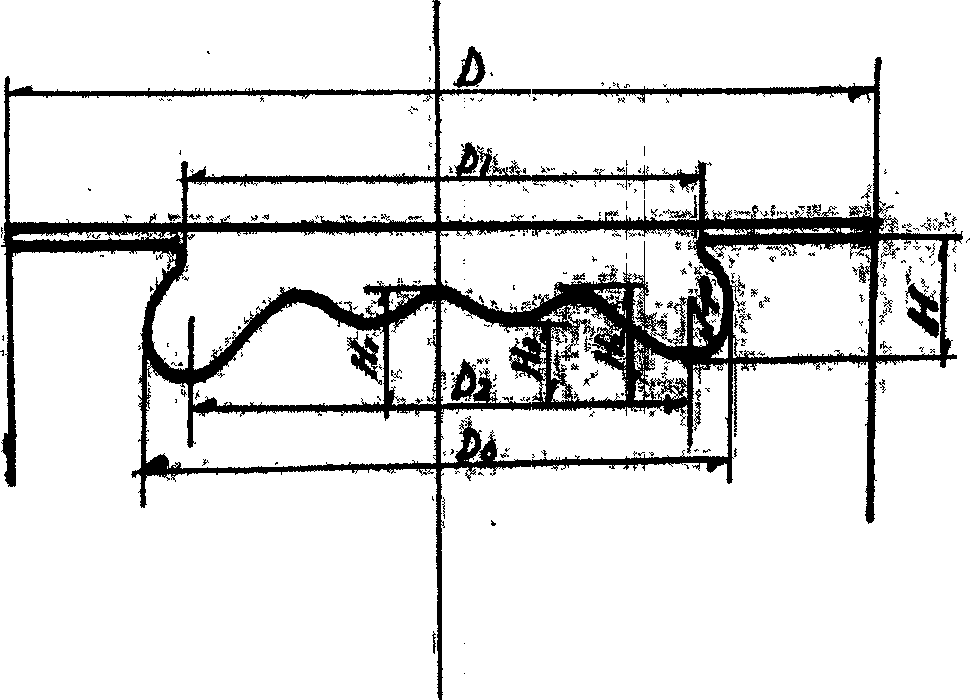

[0034] For vehicle diesel engines and other small diesel engines, the combustion chamber can be figure 2 The scheme is characterized in that the size ratio of the multi-communication space combustion chamber is such as figure 2 Shown: D1 / D=0.45~0.65; D0 / D=0.5~0.75; H / D=0.15~0.30; H1 / H=0.5~0.75;

[0035] H2 / H=0.5-0.75; H3 / H=0.3-0.6; R / H=0.28-0.4.

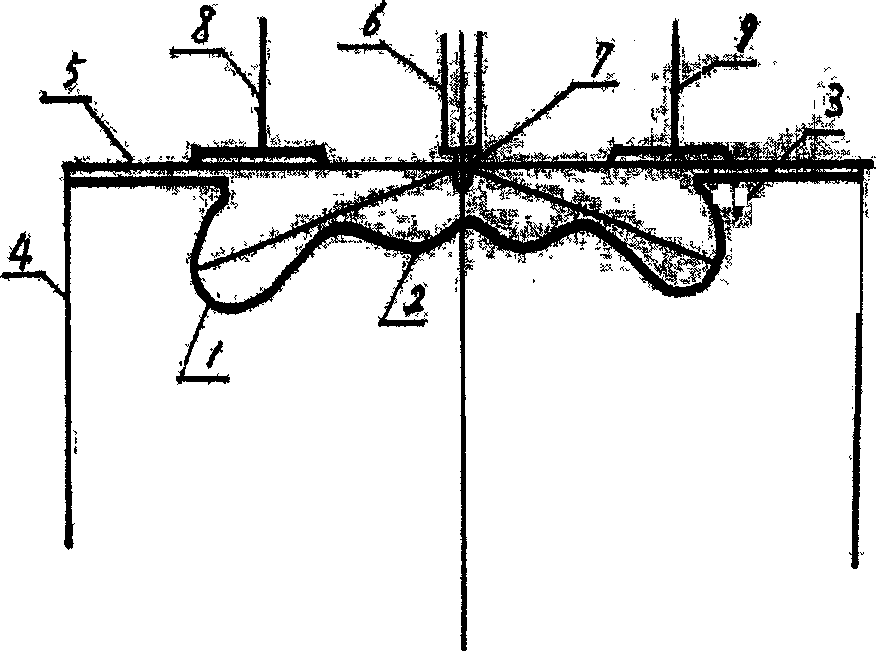

[0036] The combustion chamber can adopt the scheme of closing or not closing. The volume ratio of the central combustion chamber and the peripheral combustion chamber is usually 1 / 5 to 1 / 3. The entire combustion system is figure 1 Shown:

[0037] The oil nipple and the oil beam are designed according to the following two schemes. The feature of the first plan is that the fuel injector has 6-20 oil holes with a diameter of 50-180 μm, the center line of the fuel injector coincides with the center line of the combustion chamber, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com