Auxiliarily burning reactor and its application in vapor process of preparing nano SiO2

A technology of combustion reaction and assisted combustion, applied in the direction of silicon oxide, etc., can solve the problems of difficulty in preparing high-quality nano-SiO2 products, uneven residence time distribution, uneven temperature field and concentration field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

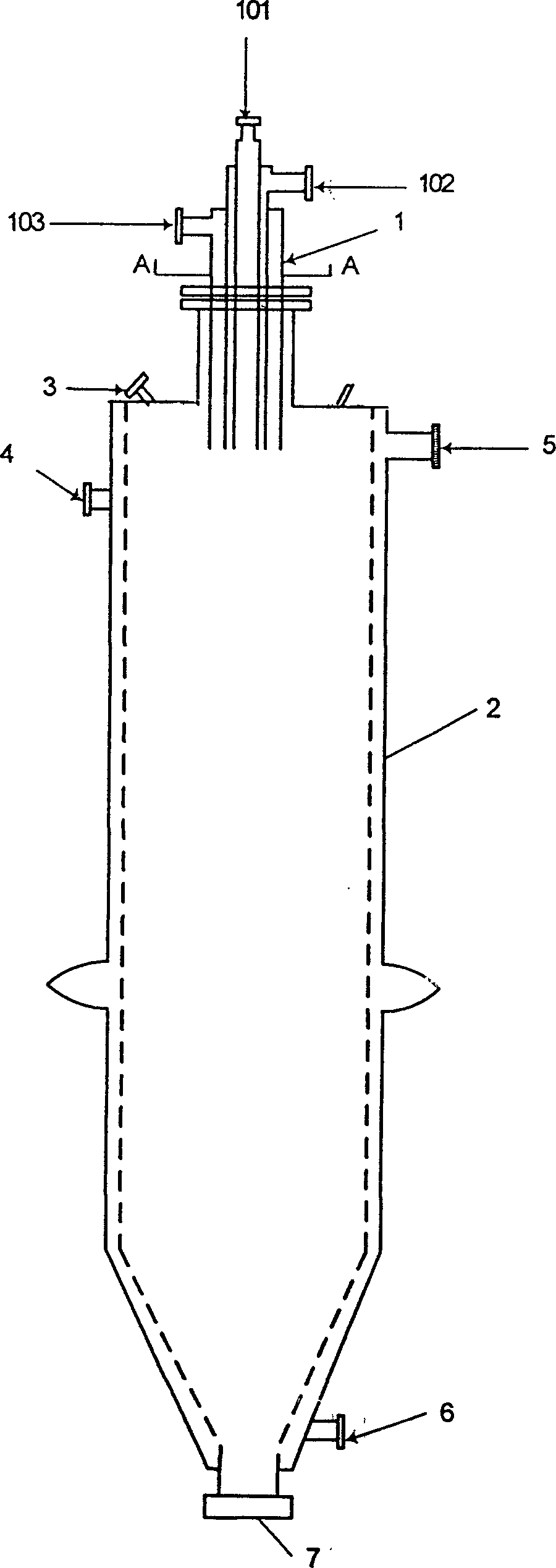

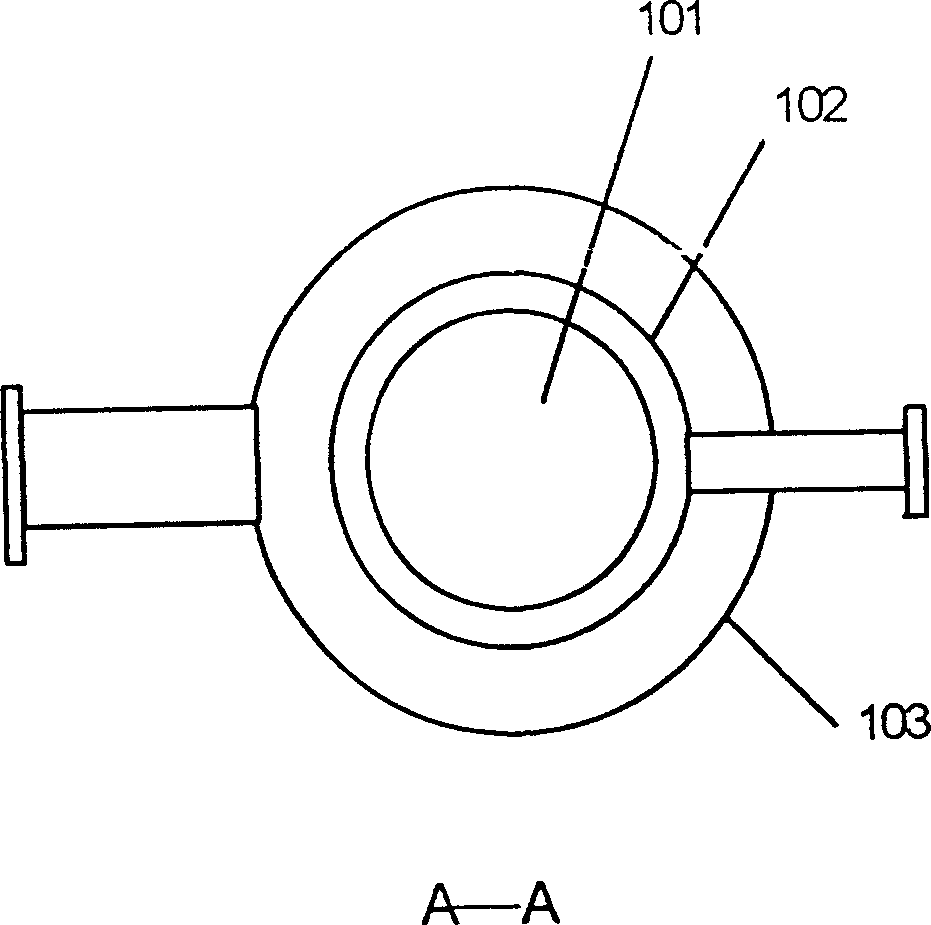

[0027] The liquid silicon tetrachloride is vaporized by electric heating, and its steam is mixed with the dried, purified and preheated air into the mixer through the tee, and at the same time, the hydrogen gas is also passed into the mixer after being dried and purified. After the three gases are pre-mixed according to the reaction theoretical ratio (considering that the first-time mixing is not necessarily uniform, so two mixers are connected in series), they are introduced into the central tube of the reactor and ejected at high speed, and the total gas velocity at the central tube outlet is 76.2 m / s (hydrogen, Air and silicon tetrachloride vapor according to the chemical ratio), ignition combustion reaction. Because the flame combustion of the above-mentioned mixed gas is easy to extinguish, so another purified air and excess hydrogen are mixed through a tee and then passed into the second ring of the reactor. "Long-lived fire" to ensure the stable burning of the central f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com