Spark-ignition four-stroke engine

A four-stroke engine, spark ignition technology, applied in spark ignition controllers, engine ignition, engine components, etc., can solve problems such as poor ignition, easy cooling of the ignition plug, and smoke from the ignition plug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described with reference to an embodiment of the present invention shown in the accompanying drawings.

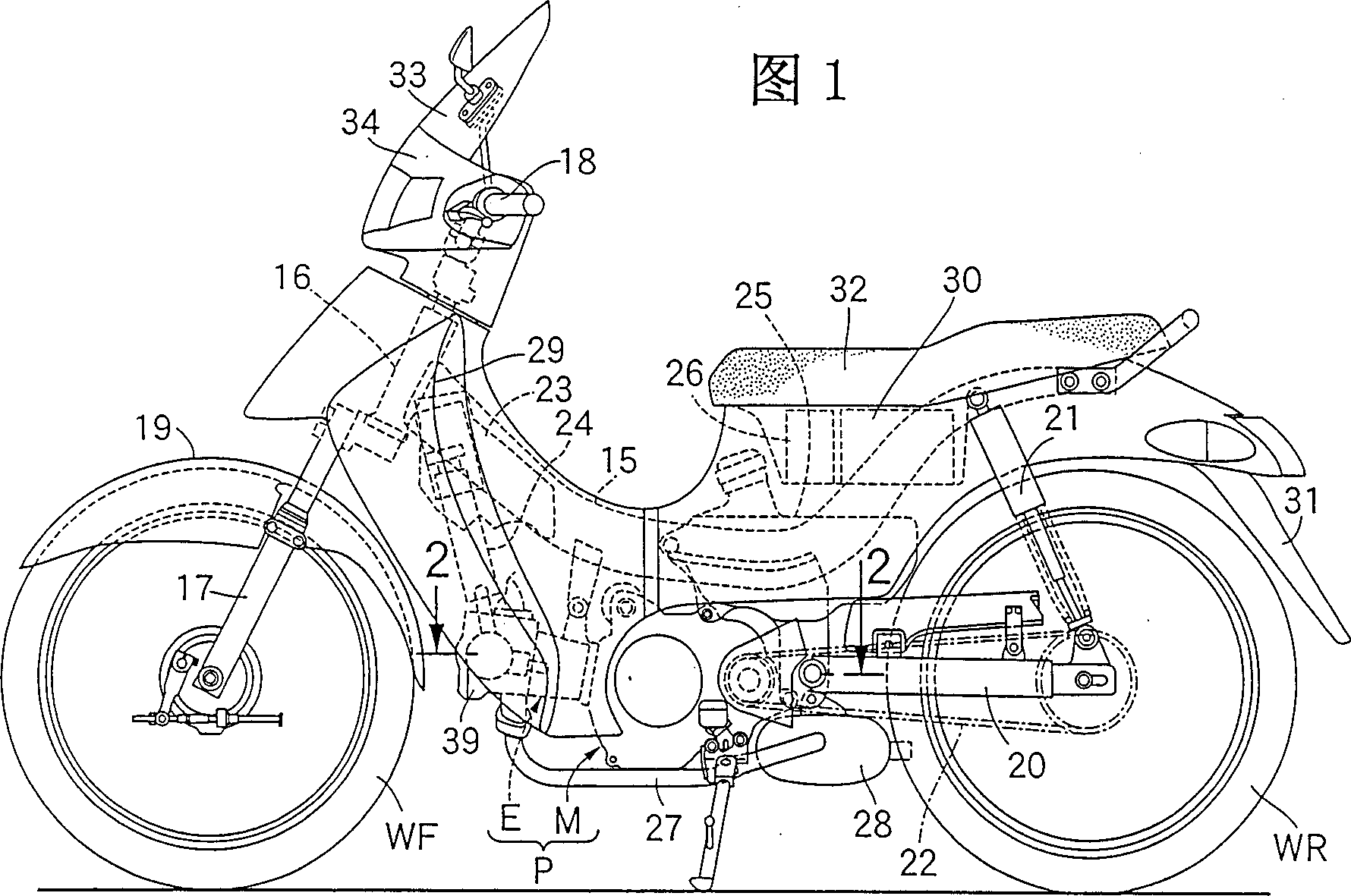

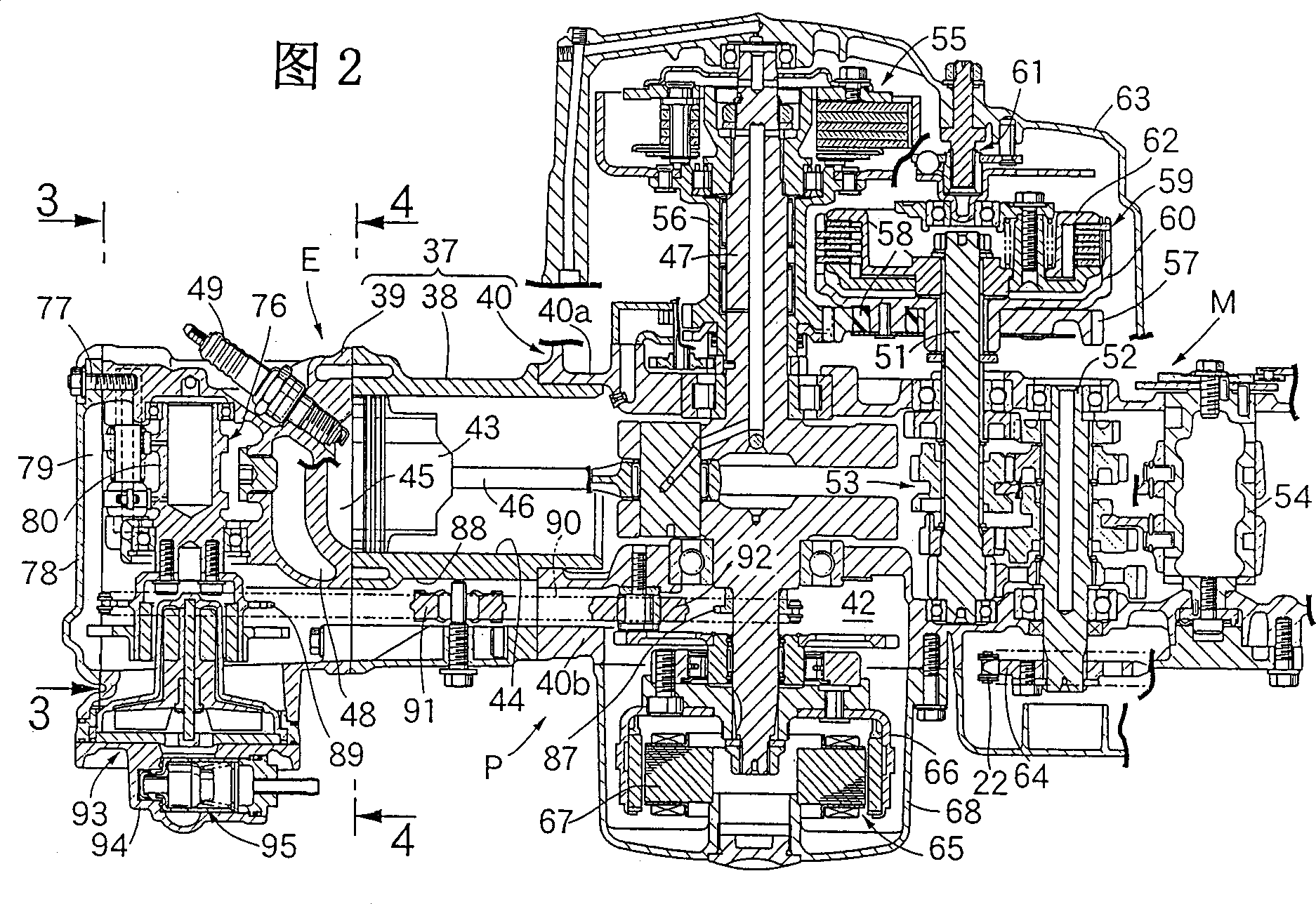

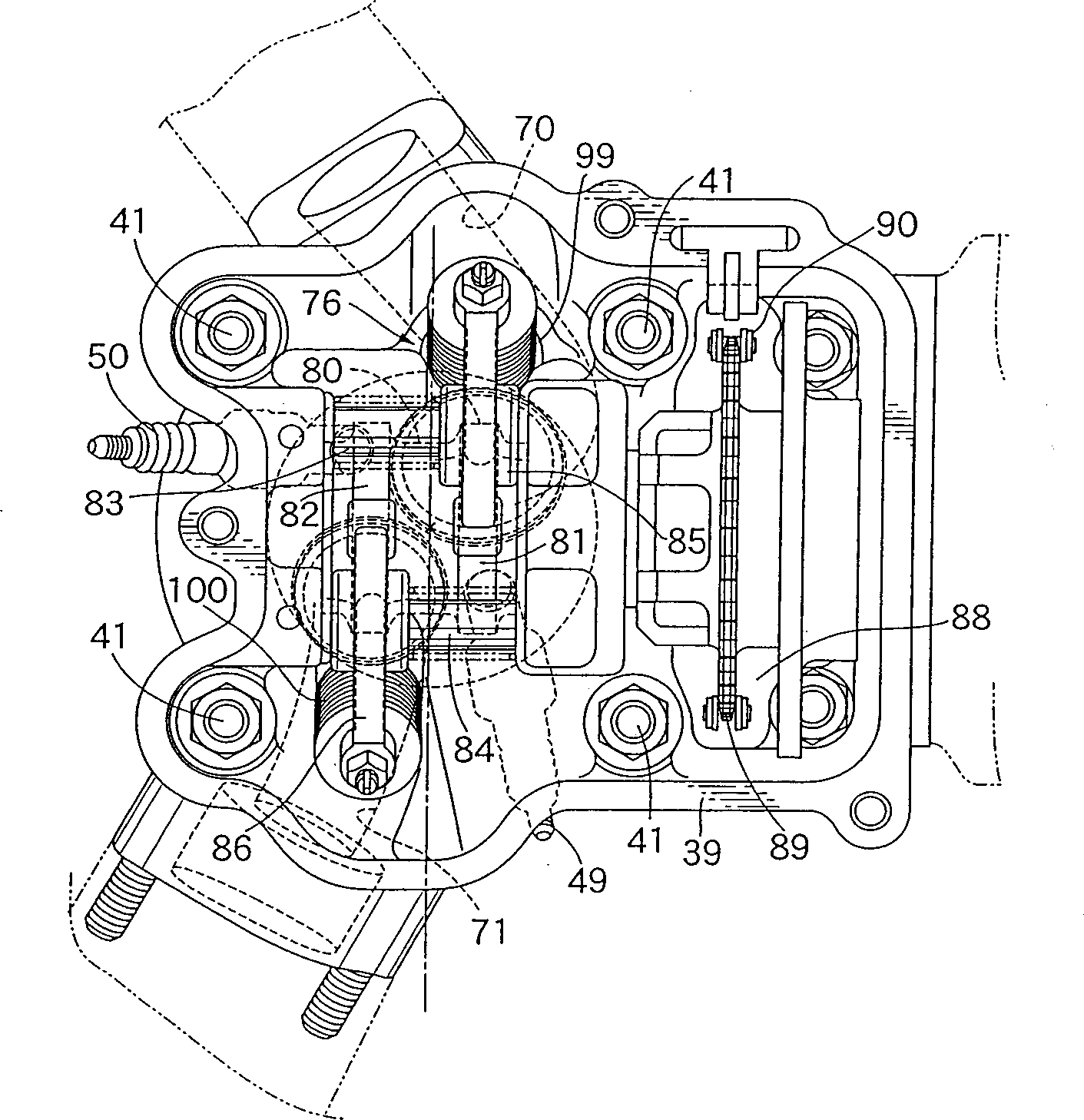

[0019] Figure 1 to Figure 8 An example of the present invention is shown. Fig. 1 is a side view of a two-wheeled motor vehicle. Fig. 2 is a sectional view of the power unit along line 2-2 in Fig. 1 . image 3 It is an enlarged view of line 3-3 in Figure 2. Figure 4 It is the magnified sectional view of line 4-4 in Fig. 2. Figure 5 yes Figure 4 The 5-5 line section diagram. Figure 6 yes Figure 5 6-way view in . Fig. 7 is a projection view of the intake port toward a plane perpendicular to the axis of the cylinder bore. Figure 8 yes Figure 5 The 8-8 line section diagram.

[0020] As shown in FIG. 1, a front end of a frame 15 of a motorcycle is provided with a head pipe 16, and a front fork 17 pivotally supporting a front wheel WF is pivotally supported on the head pipe 16 in a steerable manner. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com