Air discharging cover for range hood

A technology for air outlet hoods and range hoods, which is applied in the direction of removing oil fumes, applications, and household stoves. It can solve the problems of slow closing of the valve plate, affecting the sealing effect, and large gaps, and achieves reliable sealing, prevents smoke from falling, and is simple to manufacture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

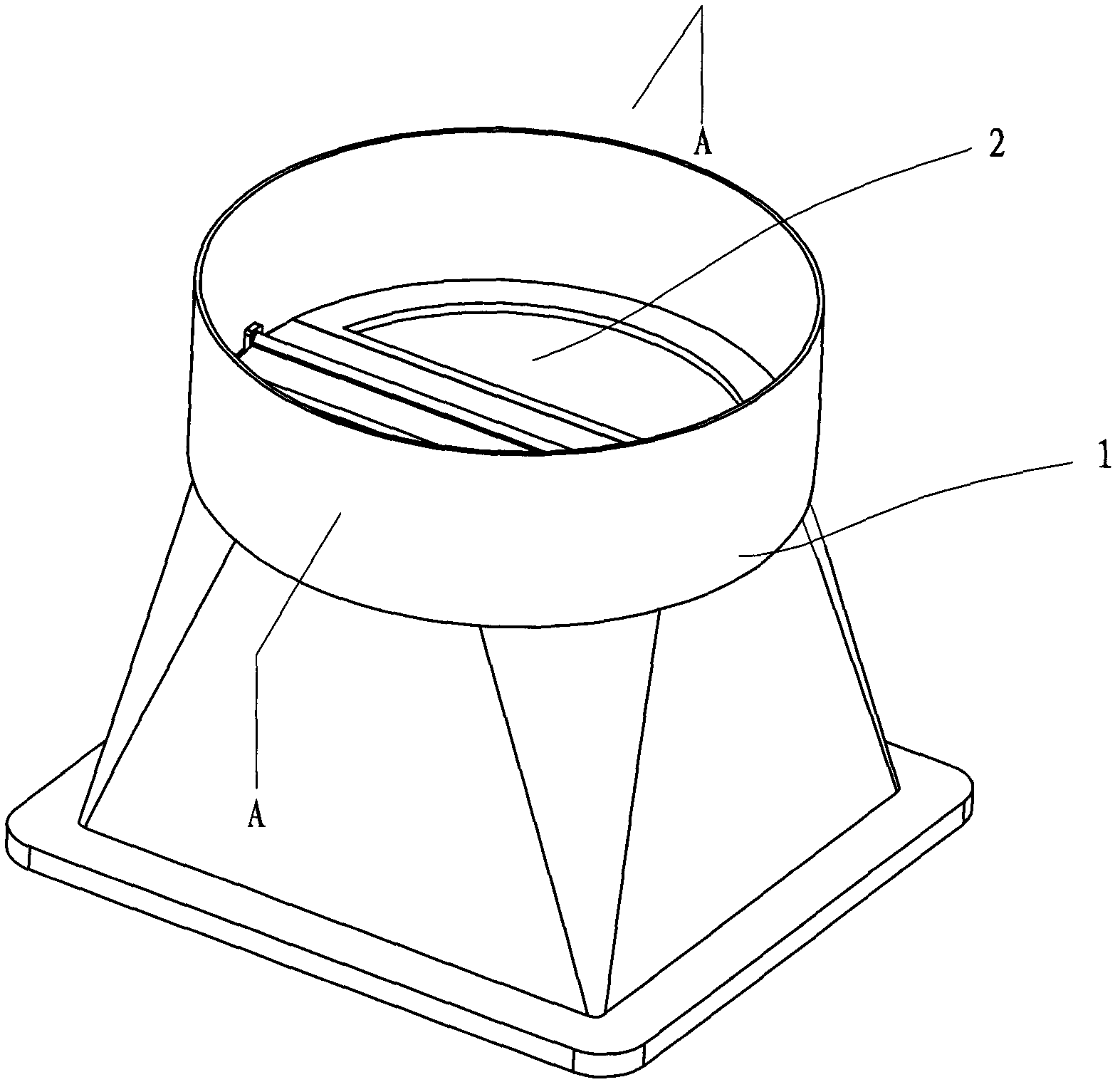

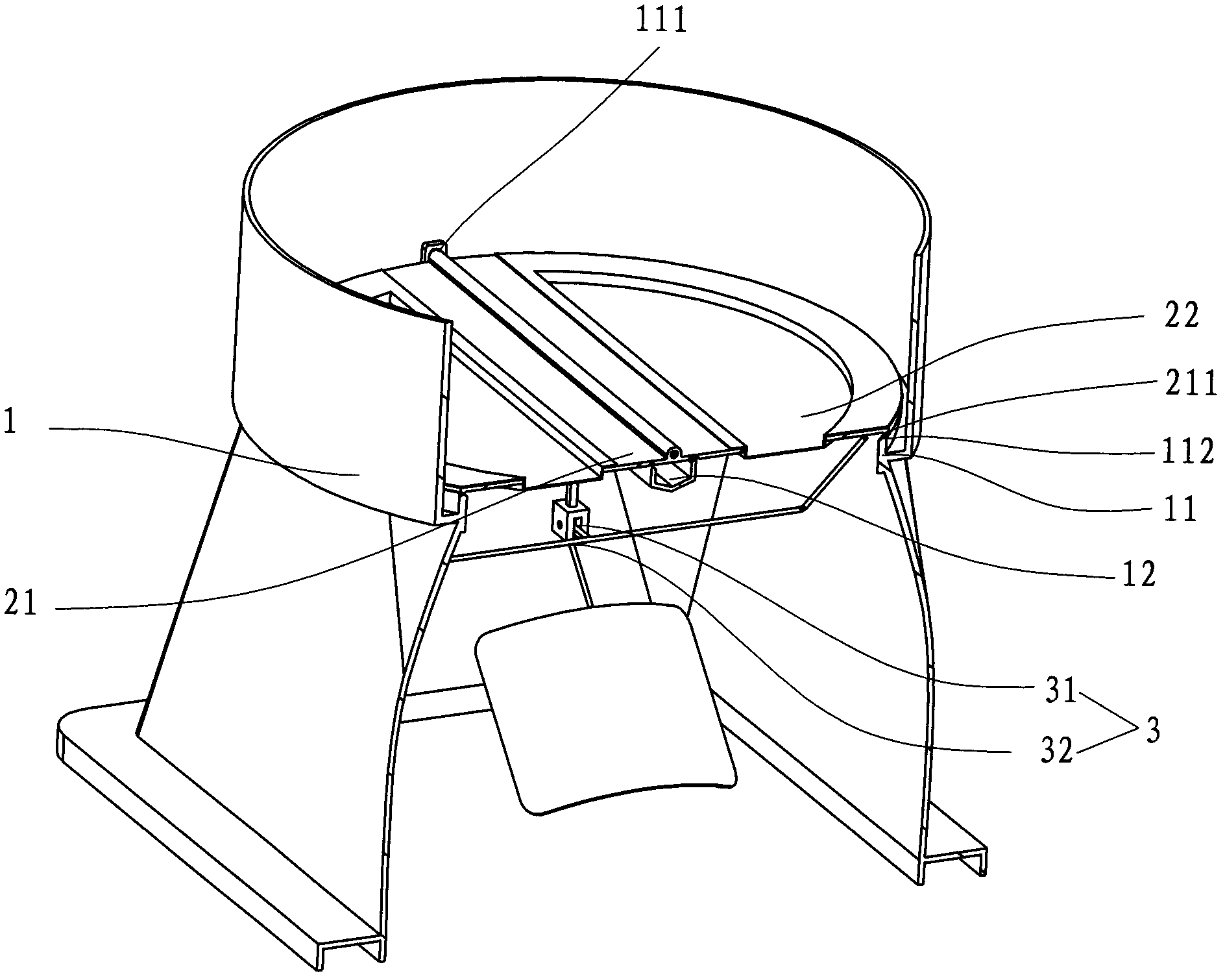

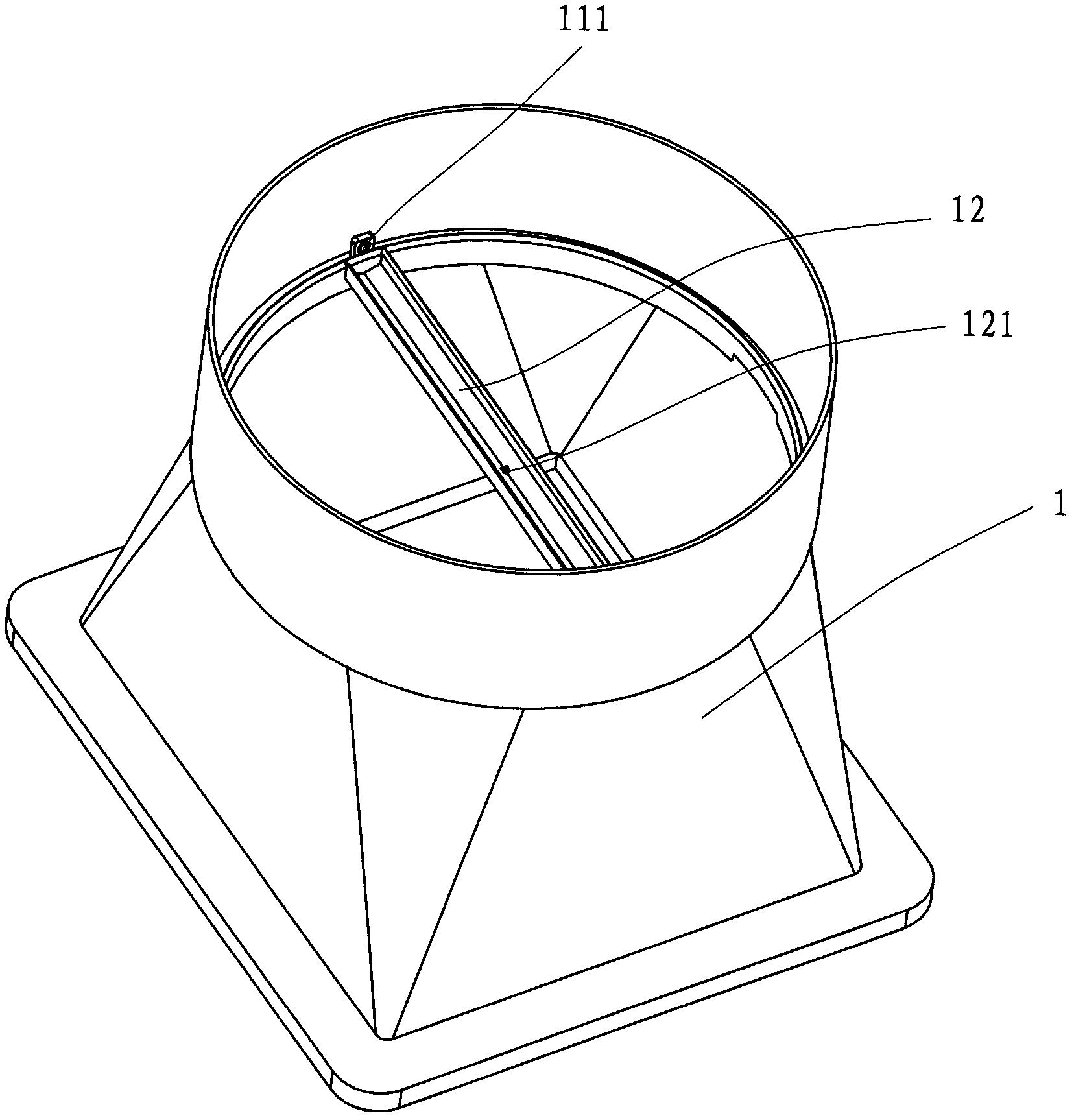

[0027] see figure 1 , figure 2 and Figure 4 , a non-return valve for anti-dumping smoke and anti-sticking range hood, comprising a cover body 1, a check valve plate assembly 2 arranged in the cover body 1, and a connecting rod assembly 3 connected to the lower surface of the check valve plate assembly 2.

[0028] The check valve plate assembly 2 includes a check valve plate 21 and a blocking plate 22. The check valve plate 21 is an integrally formed circular plate, preferably made of rubber. The periphery of the non-return valve plate 21 is bent downward to form an edge 211, which covers the upper edge of the inner side wall 11 of the cover body 1, so as to completely close the air outlet. The edge 211 can be as figure 2 As shown, it is preferably formed by bending downwards in a triangular shape. A circle of chamfers 112 is formed at the position where the upper edge of the inner sidewall 11 is in contact with the non-return valve plate 21, which can be formed on the i...

Embodiment 2

[0037] see Figure 6 and Figure 7 , a non-return valve for anti-dumping and anti-sticking range hoods, comprising a cover body 1', a non-return valve assembly 2' arranged in the cover body 1', and a connecting rod connected to the lower surface of the non-return valve assembly 2' components (not shown). The difference from Embodiment 1 is that the check valve plate assembly 2' includes two symmetrical check valve plates 21', and the link arm of the connecting rod assembly is connected to the lower surface of the check valve plates 21'. Check valve plate 21 ' is semicircular, is connected with rotating shaft 5 between, and the two ends of rotating shaft 5 are fixed in the cover body 1 '. At the junction of the two check valve plates 21' and the rotating shaft 5, an oil-resistant adhesive tape 6 is pasted. The reverse valve plate 21' can cover the air outlet more tightly to prevent smoke from pouring down and smell passing through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com