Air outlet hood for range hood

A technology for air outlet hoods and range hoods, which is applied in the direction of removing oily fumes, applications, household stoves, etc. It can solve the problems of affecting the sealing effect, slow closing of the valve plate, and large gaps, so as to ensure normal operation, reliable sealing, and simple manufacture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

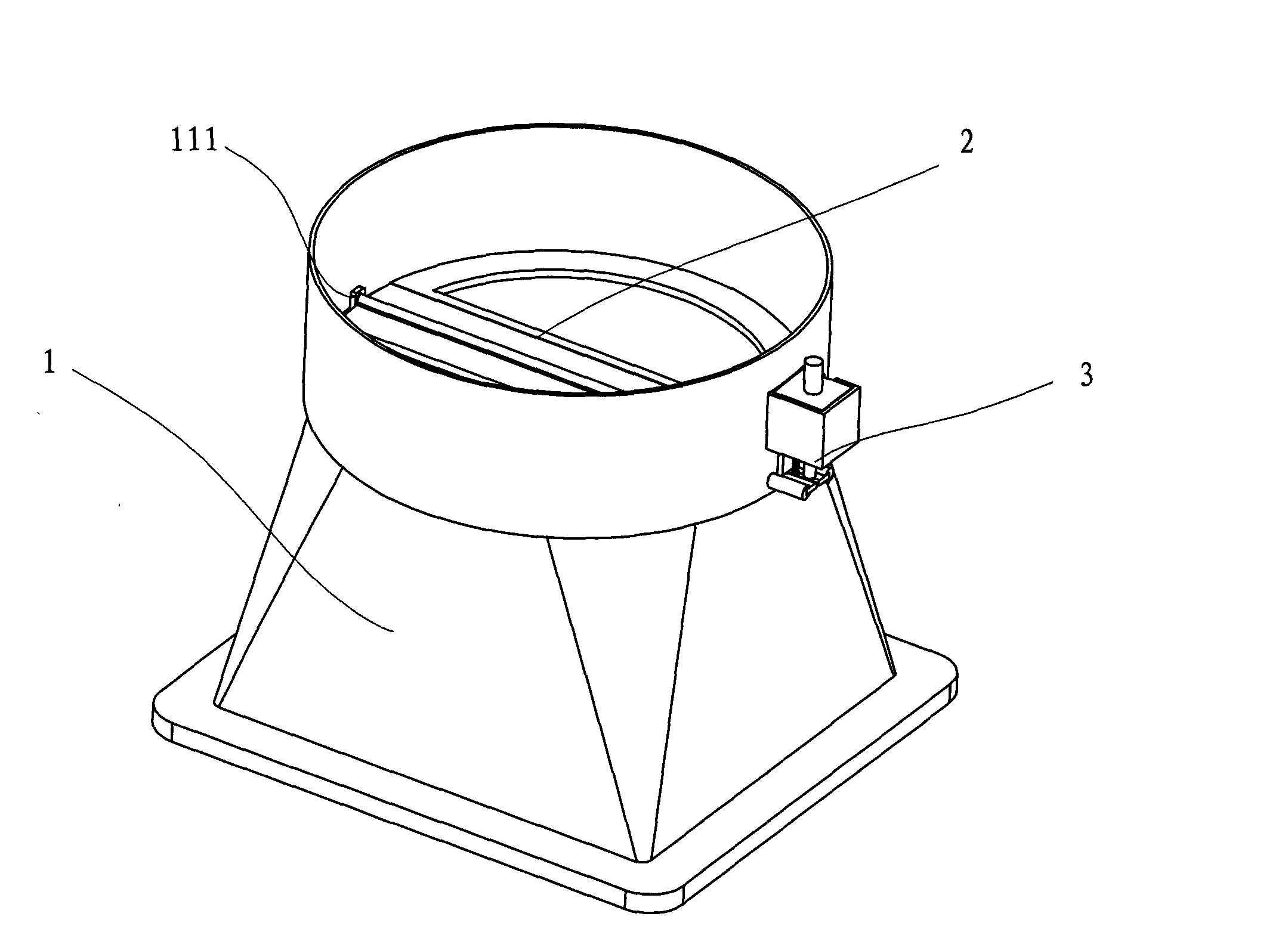

[0020] see figure 1 with figure 2 , an air outlet cover for range hoods, including a cover body 1, a check valve plate assembly 2 arranged inside the cover body 1 and a drive device 3 arranged outside the cover body 1.

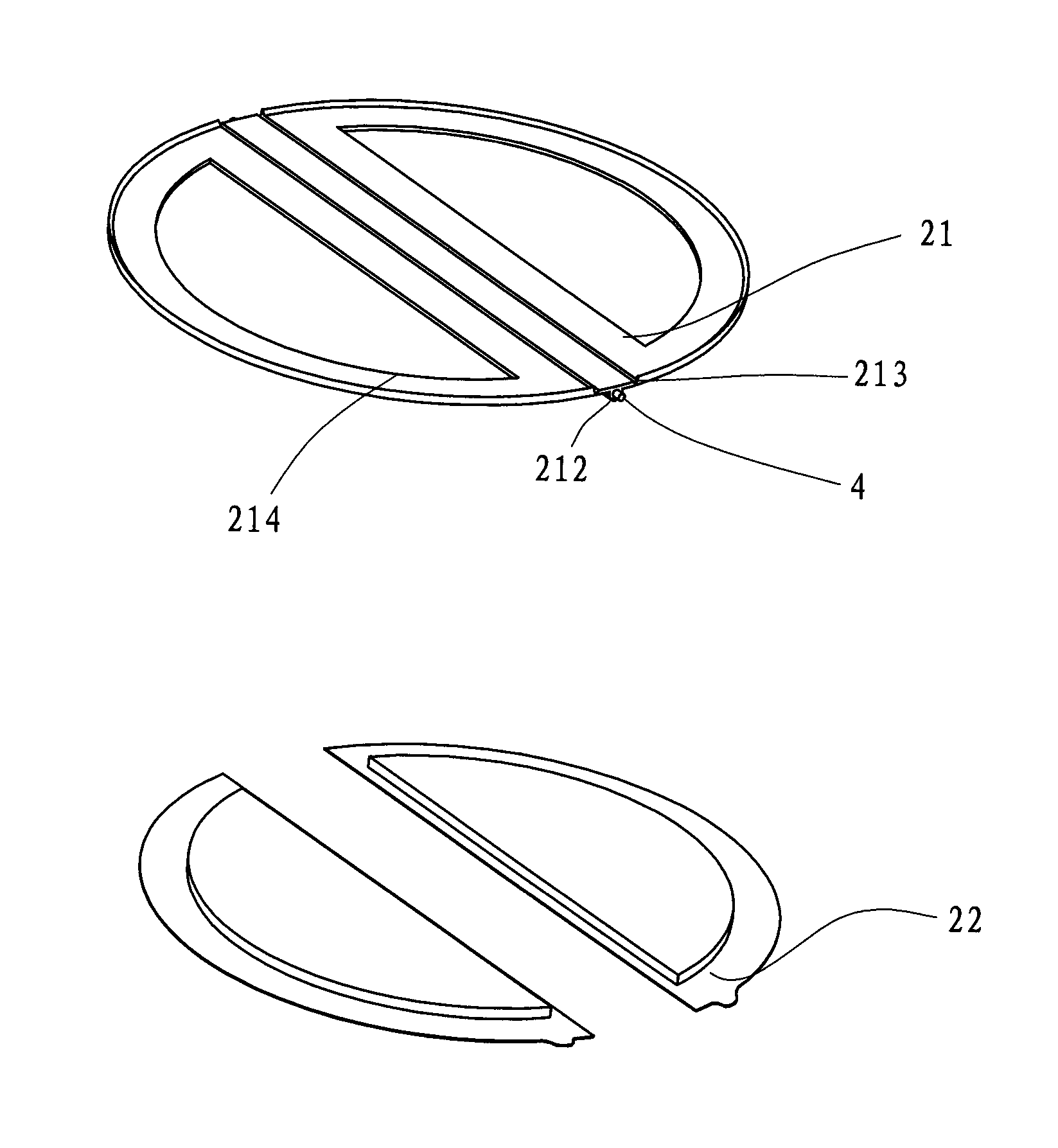

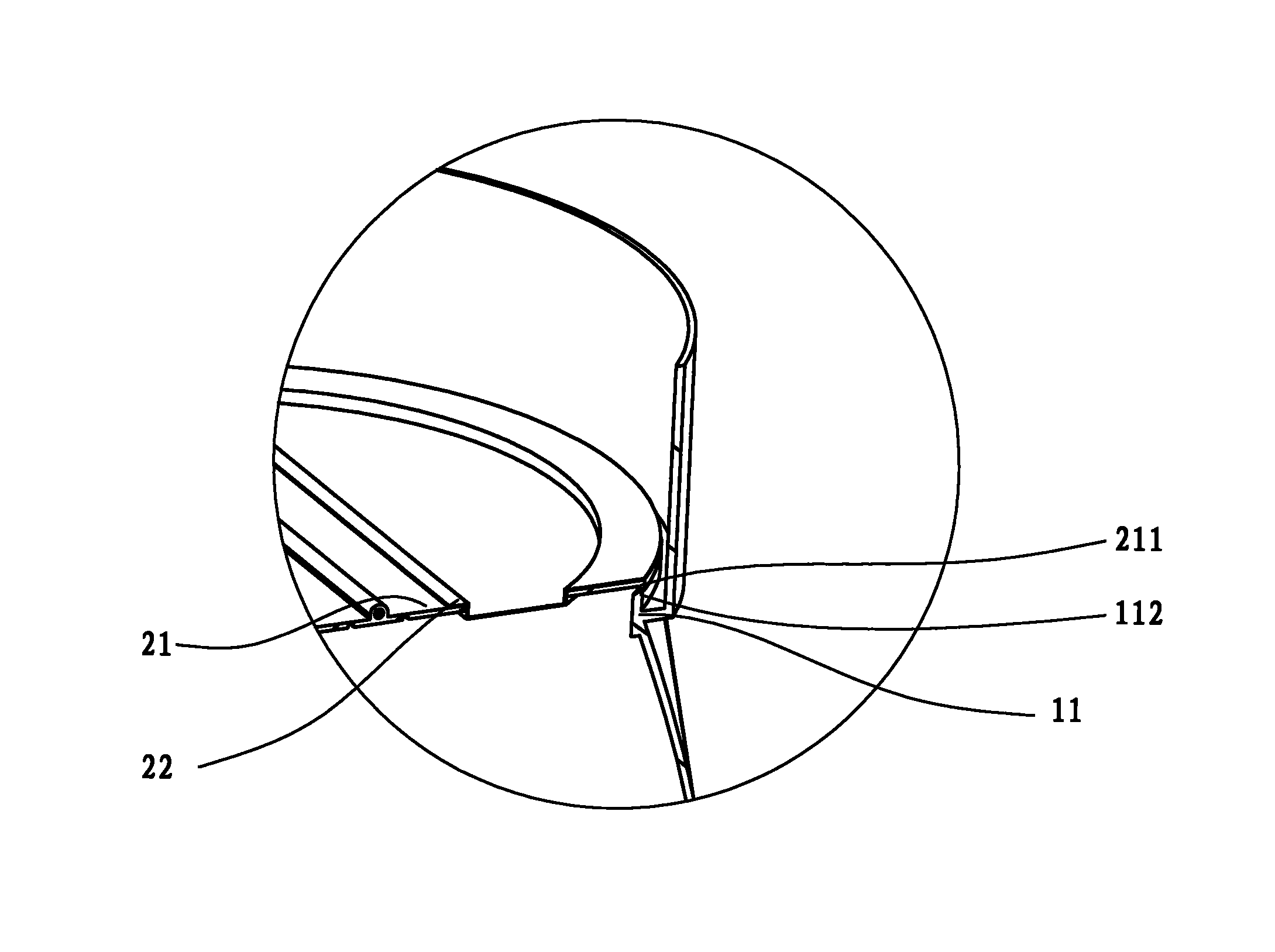

[0021] The check valve plate assembly 2 includes a check valve plate 21 and a blocking plate 22. The check valve plate 21 is an integrally formed circular plate, preferably made of rubber. The periphery of the non-return valve plate 21 is bent downward to form an edge 211, which covers the upper edge of the inner side wall 11 of the cover body 1, so as to completely close the air outlet. The edge 211 can be as image 3 As shown, it is preferably formed by bending downwards in a triangular shape. A circle of chamfers 112 is formed at the position where the upper edge of the inner sidewall 11 is in contact with the non-retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com