Full-premixing water-cooling gas boiler with U-shaped pipe structure

A gas-fired boiler, fully premixed technology, applied in burner and boiler design, safe and stable low-nitrogen combustion of natural gas, can solve problems such as uneven temperature distribution of water-cooled tube bundles, heavy transformation workload, increased process costs, etc., to achieve adaptation Strong performance, uniform flow and heat transfer, and the effect of improving boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail below in conjunction with accompanying drawing:

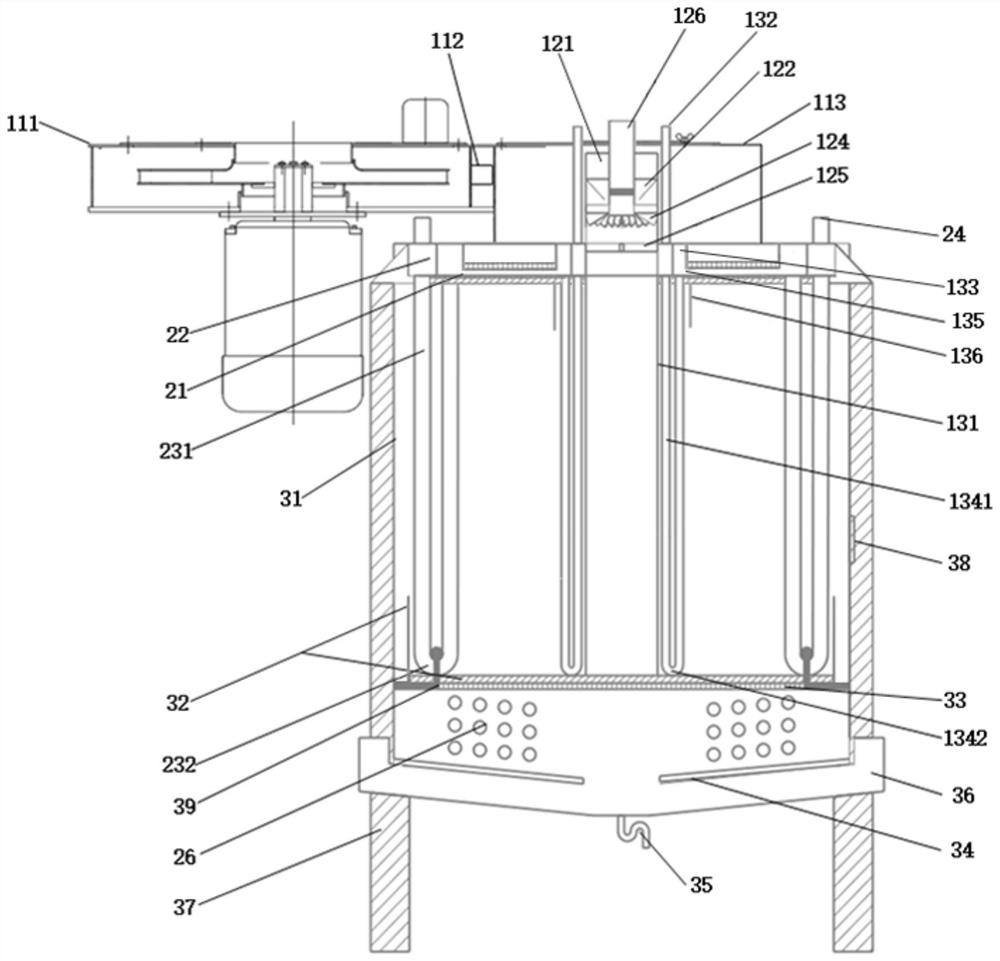

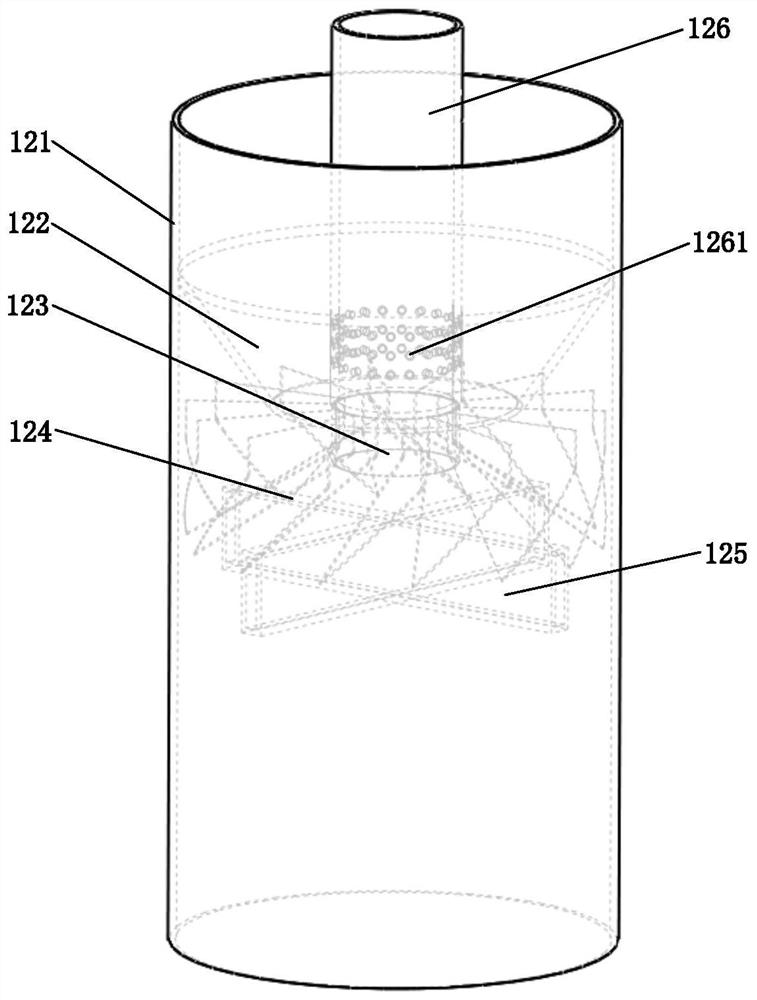

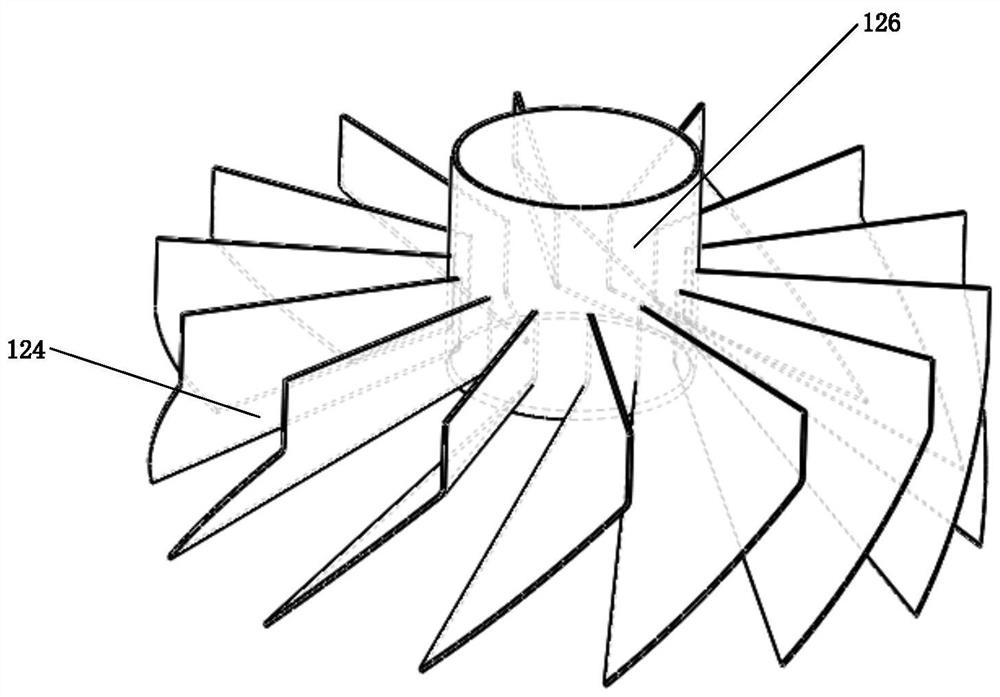

[0036] refer to figure 1, a fully premixed water-cooled gas-fired boiler with U-shaped tube structure, the boiler includes "pot" and "furnace" and other boiler components 3, "pot" refers to the water-cooled heat exchanger 2 wrapped outside the "furnace", water-cooled The heat exchanger 2 includes several heat exchanger water-cooled tube bundles; "furnace" refers to the water-cooled burner 1 wrapped in the external water-cooled heat exchanger 2 with central air intake. The water-cooled burner 1 is cylindrical as a whole, and the water-cooled burner 1 includes Several combustion head water-cooled tube bundles; the single tube bundles of the combustion head water-cooled tube bundle and the heat exchanger water-cooled tube bundle are U-shaped water-cooled tubes, and the water-cooled burner 1 and the water-cooled heat exchanger 2 on the outer ring have similar overall struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com