Rotary engine

An engine and steam turbine technology, applied in air transportation, engine cooling, climate sustainability, etc., can solve problems such as torque difference, control miscellaneous, air pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

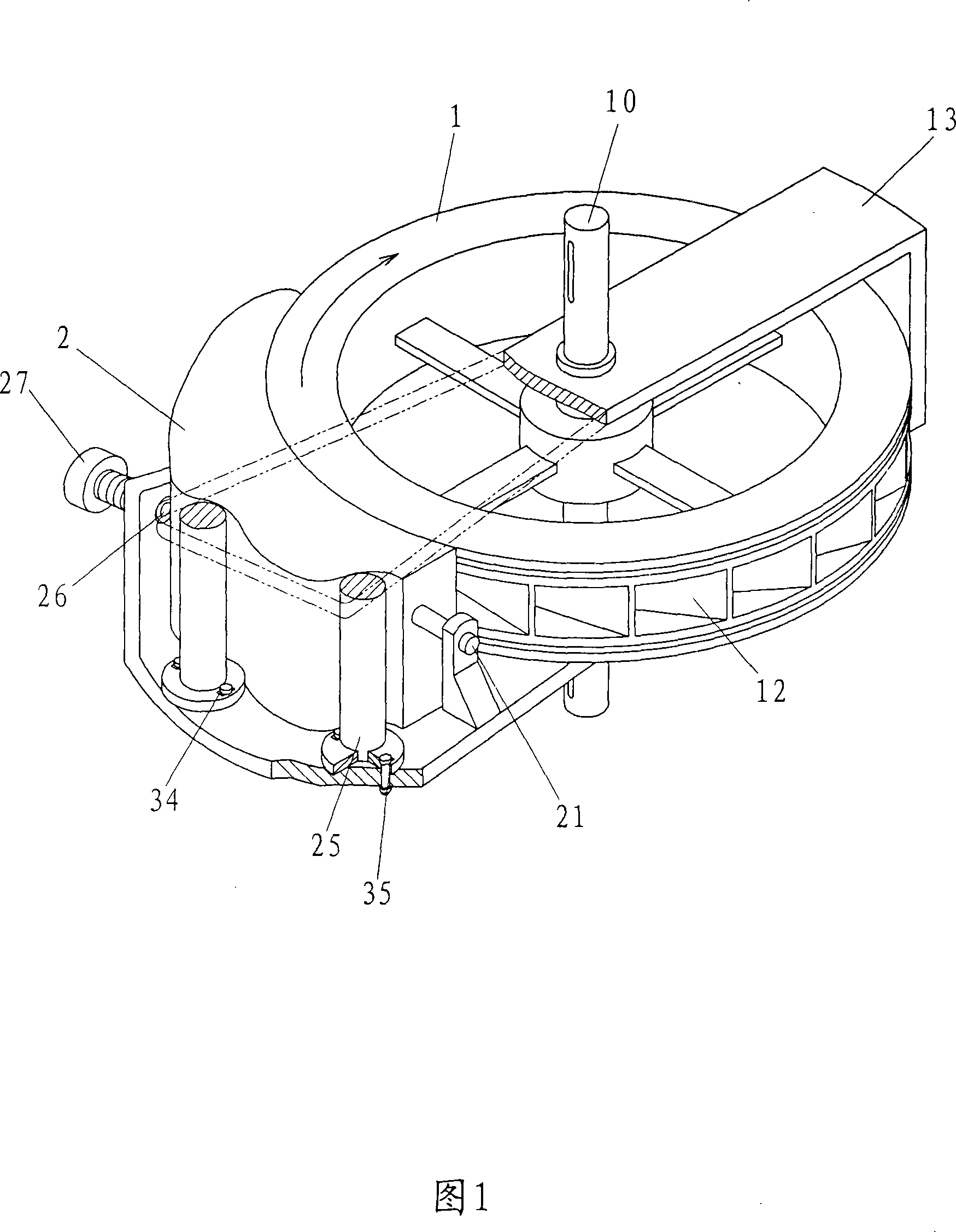

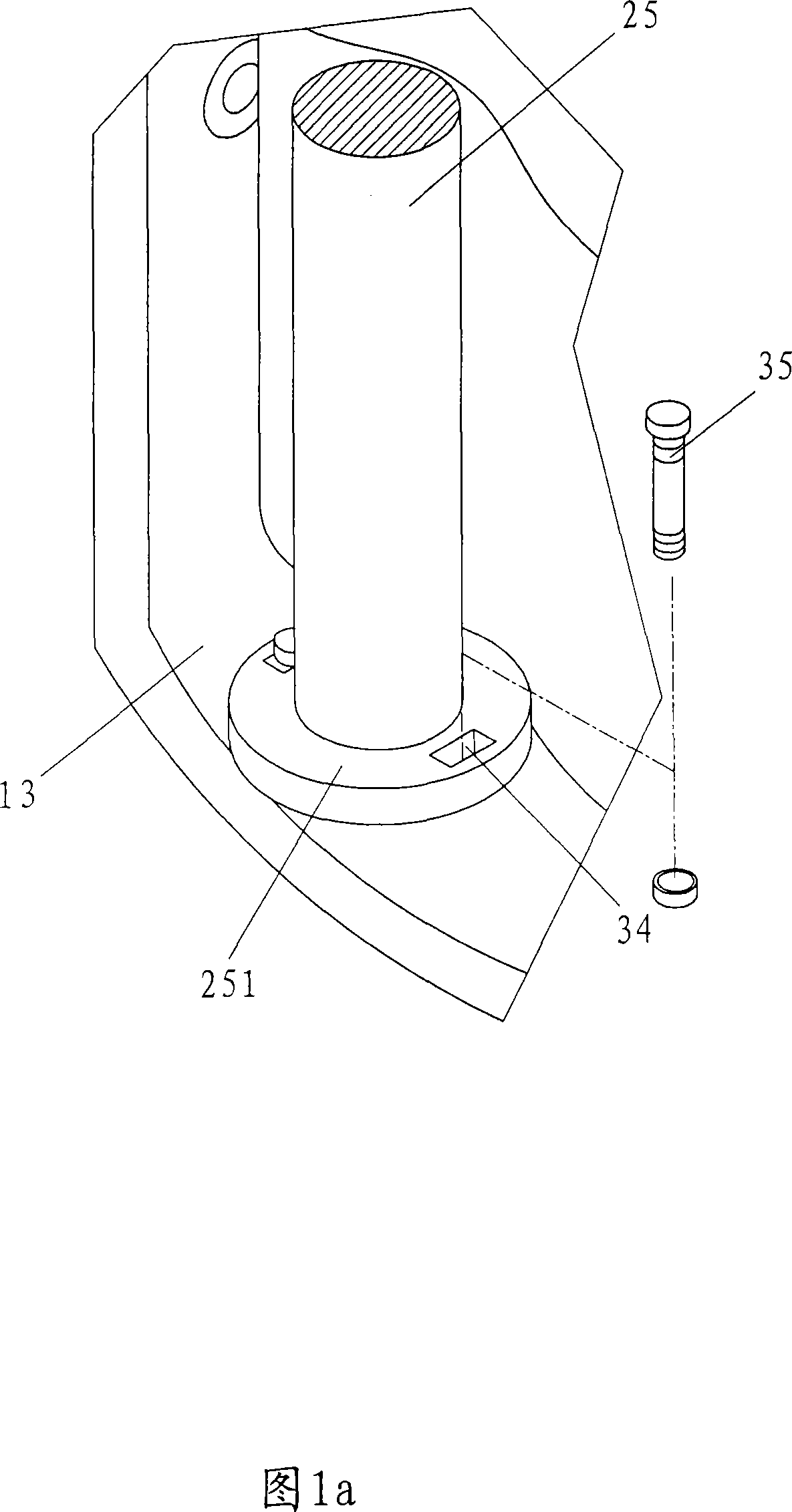

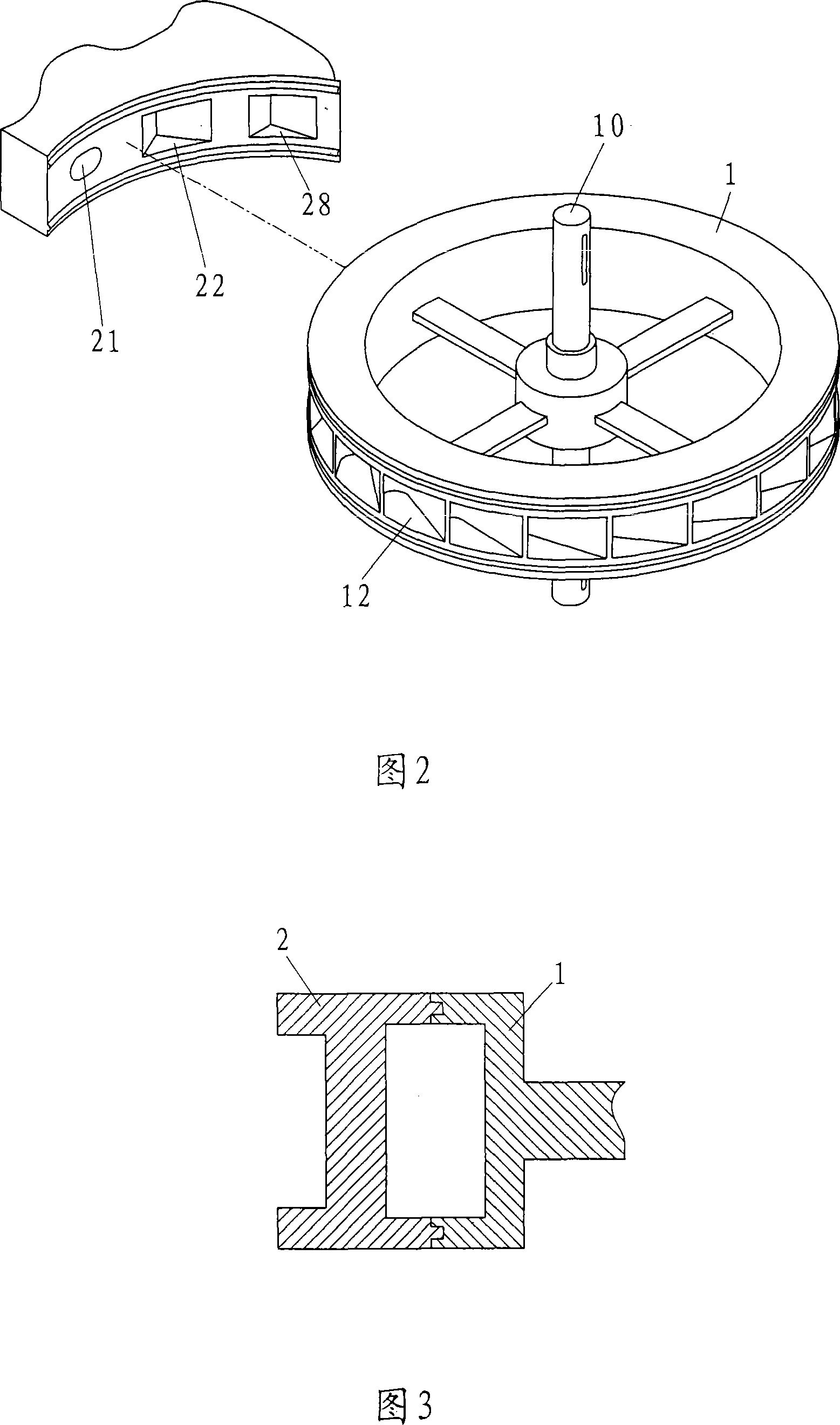

[0040] As shown in Figures 1 to 9, the rotary engine of the present invention is statically arranged on a circular steam wheel 1 by more than one slide block 2, wherein the center of the steam wheel 1 is fixed on a main shaft 10, and around the steam wheel 1 or two The side is provided with non-inverted triangular bag-shaped pistons 12 with the same arrangement pitch, and more than one slide block 2 is kept in a tight state with it in static state.

[0041] The slide block 2 is crescent-shaped, and the inner side has similar inverted triangle recesses, which respectively form a combustion chamber 22 and a power chamber 28. When 12 meets with combustion chamber 22 and power chamber 28, constitutes similar cylinder block. In addition, the inside of the slider 2 is provided with a semi-enclosed cooling chamber 3 that communicates with the power chamber 28 on one side, and an air inlet 21 is provided outside to penetrate the inside of the slider 2 . The outer side of the slider 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com