Device for treating liquefiable foundation by using vibratory hammer pipe and treatment method thereof

A technology of liquefied foundations and vibratory hammers, applied in soil protection, foundation structure engineering, sheet pile walls, etc., can solve the problems of strong vibration energy affecting the surrounding environment, muddy water pollution, and weak ability to penetrate the soil layer. Achieve the effects of low noise and vibration, convenient movement, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

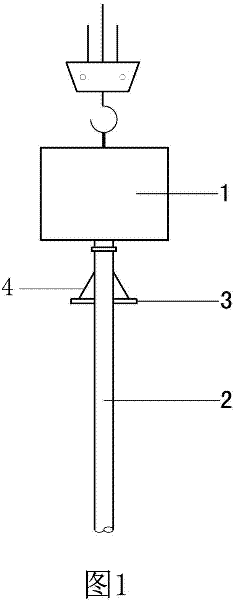

[0056] Embodiment one sees figure 1As shown, a device for treating liquefied ground with a vibratory hammer tube includes a vibratory hammer 1 and a core tube 2. The core tube 2 is arranged under the vibratory hammer 1 and connected with the vibratory hammer 1 by flange or welding. The power of the vibratory hammer motor is 10KW-80KW, the power of the vibratory hammer motor is 10KW-80KW, the core tube is a seamless steel pipe with a circular or polygonal cross-section, and the diameter of the circular cross-section or the diameter of the inscribed circle of the polygon It is 100mm ~ 300mm, and its free end is open or closed. A fixed pressure plate 3 is hooped on the outer surface of the core tube, and the pressure plate 3 is circular or square. Strengthening ribs 4 distributed radially from the axis of the core tube are arranged between the pressure plate 3 and the core tube 2 .

Embodiment 2

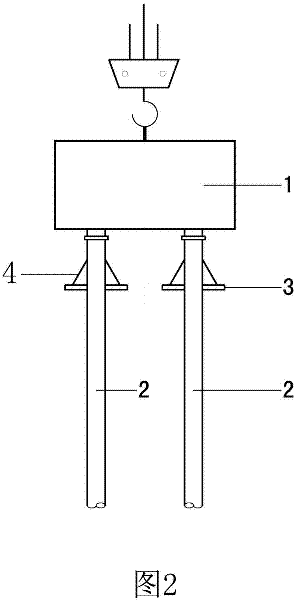

[0057] Embodiment two see figure 2 , the difference from Embodiment 1 is that the core tube is a double tube.

Embodiment 3

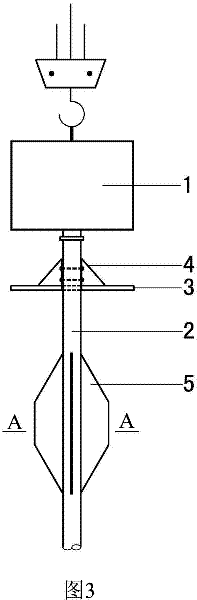

[0058] Embodiment three see image 3 and Figure 4 , different from Embodiment 1, the pressure plate 3 is detachably connected to the core pipe through bolts, and the position of the pressure plate can be adjusted along the axial direction of the core pipe. The position of the pressure plate can be liquefied according to the thickness and The length of the core tube is determined, and the pressure plate connected with the core tube is generally close to the vibrating hammer. The core tube is provided with a set of reinforcing wings along its axial direction, each set of reinforcing wings has 4 pieces, and each piece of reinforcing wings is welded to the outer surface of the core tube. The reinforcing wings are steel plates with a height of 400mm to the same length as the core pipe and a width of 0-800mm. The reinforcing wings are trapezoidal reinforcing wings 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com