Dual-power disc type DC brushless motor

A DC brushless motor, dual power technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit shape/style/structure, etc., can solve the problems of poor heat dissipation conditions, high energy consumption, hidden safety hazards, etc., to achieve a firm and stable structure, Long service life, low noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

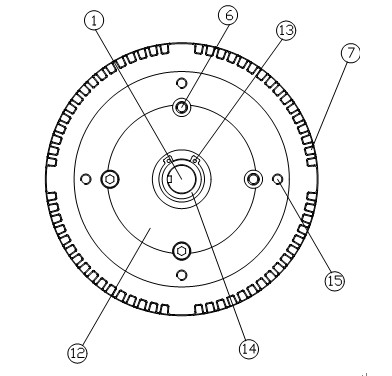

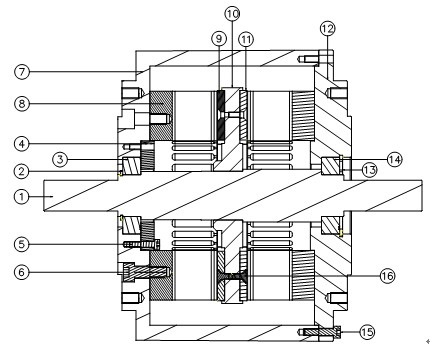

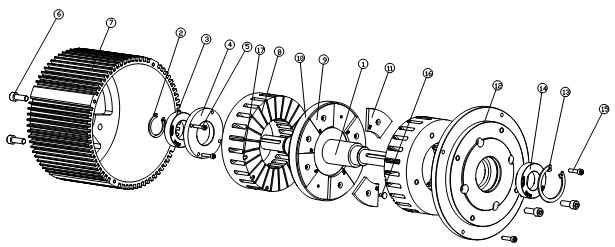

[0012] Embodiment 1, such as figure 1 , 2 , 3, a dual-power disc brushless DC motor, including a rotating shaft 1, sealed ball bearings 3, 14, positioning ring 4, motor housing 7, coil assembly 8, rotor disc 10, motor rear cover 12, Hall sensor 17, the rotor disk 10 is sleeved in the middle of the rotating shaft 1, and the two surfaces of the rotor disk 10 are respectively embedded with S pole permanent magnets 9 and N pole permanent magnets 11, which are tightened and fixed by M4 flat head screws 16, and the two sides of the rotor disk 10 Coil assemblies 8 are provided respectively, sealed ball bearings 3, 14 are respectively provided at the left and right ends of the rotating shaft 1, the motor housing 7 and the motor rear cover 12 are respectively sleeved on the sealed ball bearings 3, 14 on the left and right ends of the rotating shaft 1, and then The circlips 2 and 13 are fixed and connected together, and the positioning ring 4 is installed between the right-end sealed b...

Embodiment approach 2

[0013] Embodiment 2, the present invention can also be applied in the field of wind power generation. In the case of weak wind, the wind power generator does not need a high-power motor, so only one coil assembly 8 in the motor is required to run to generate electricity, which is beneficial to saving. When the wind generator is under strong wind conditions, a high-power motor is needed at this time. At this time, let the two coil assemblies 8 run simultaneously to generate electricity, and choose single power or dual power according to the needs. It is easy to operate and has various operating modes. One machine with multiple functions , to expand the field of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com