Isolated disinfection and washing integrated machine

An isolated, all-in-one technology, used in washing devices, other washing machines, washing machines with containers, etc., can solve the problems of large equipment, cross-infection, and inability to apply disinfection, and achieve the effect of reducing manual operations and preventing cross-infection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

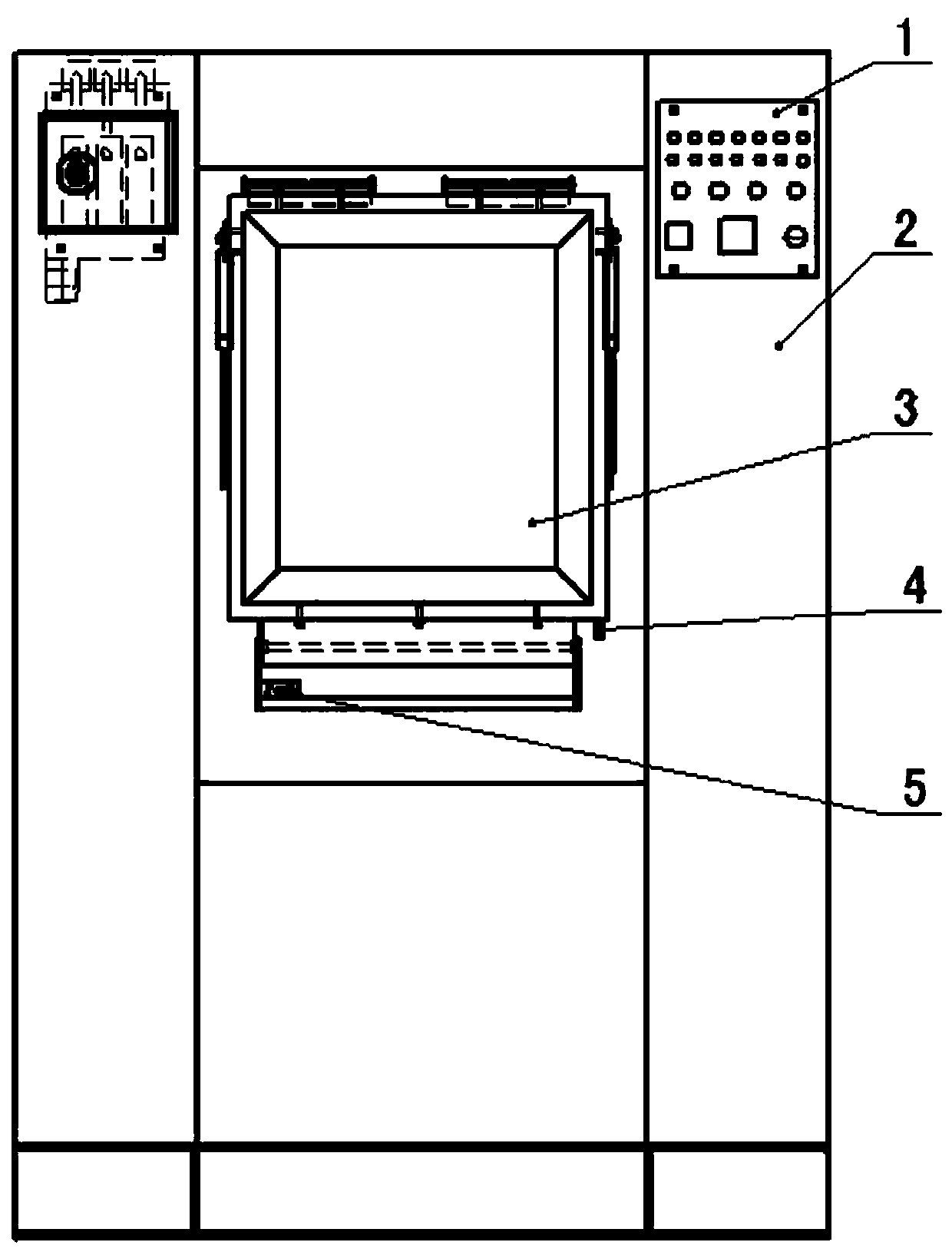

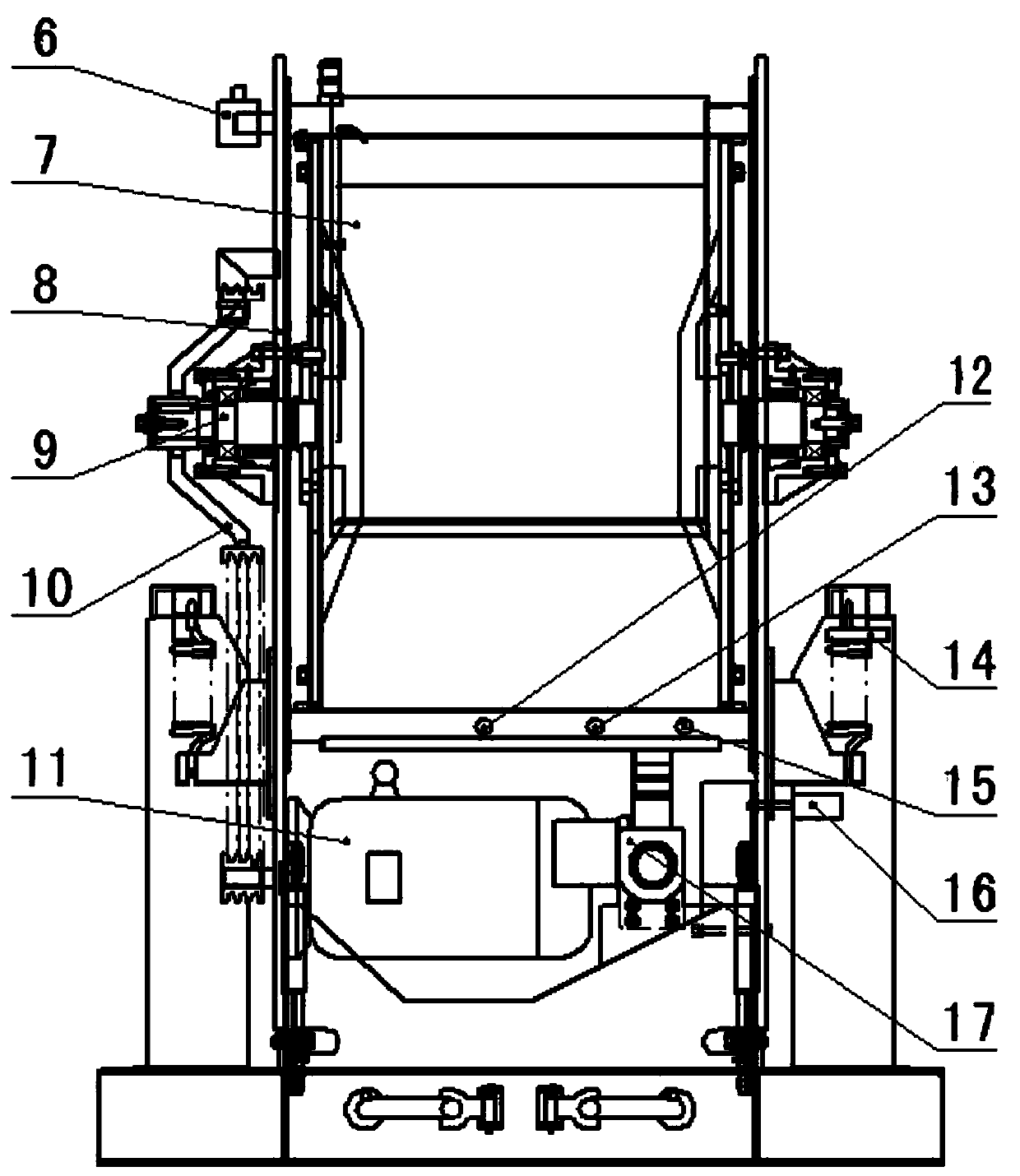

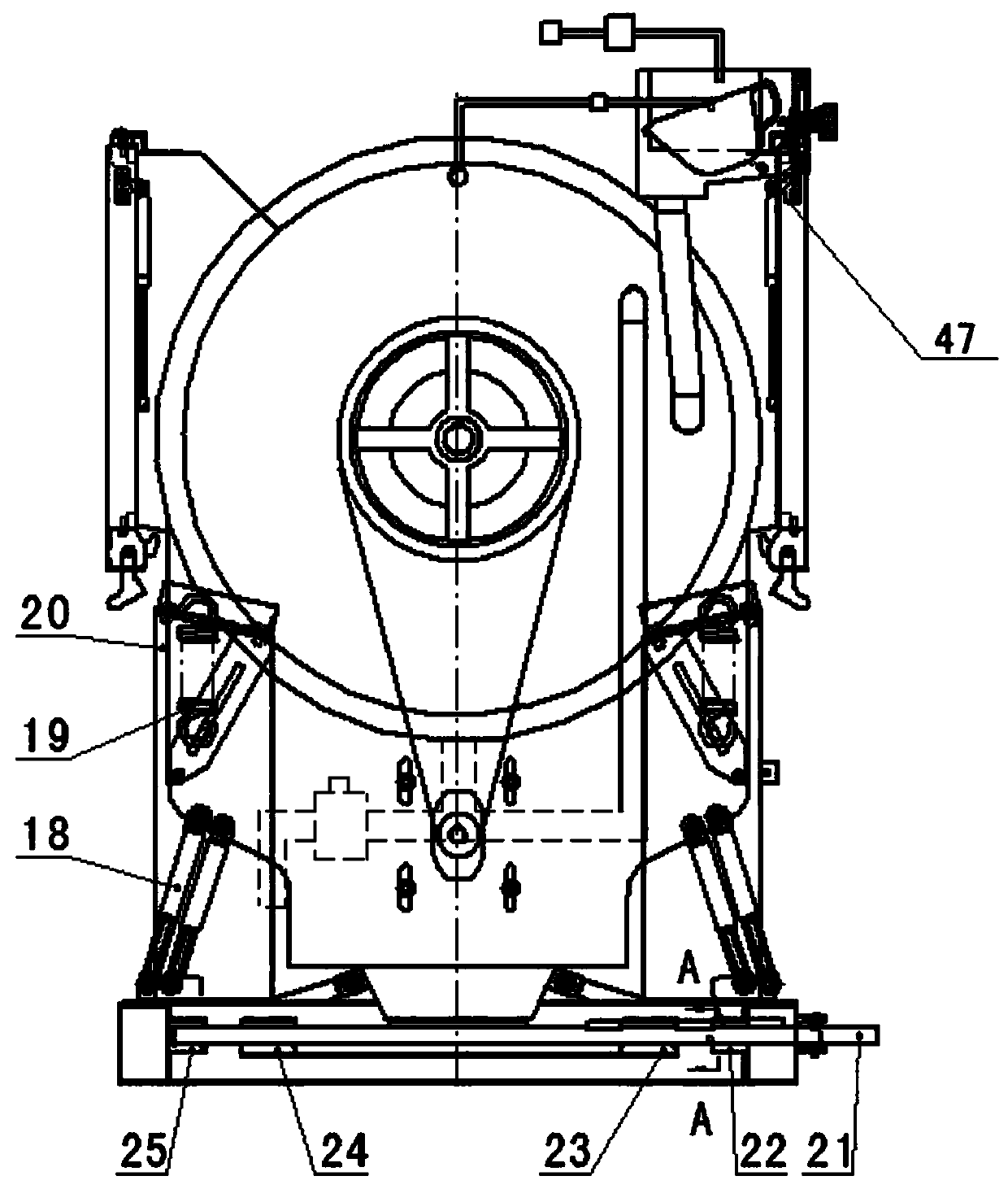

[0040] An isolated disinfection and washing all-in-one machine, its structure is as follows Figure 1 to Figure 4 As shown, it includes a frame 20, an inner drum 7 and an outer drum 8, the outer drum 8 is installed in the frame 20, a motor 11 is installed on the frame below the outer drum 8, and a main shaft assembly 9 is fixedly arranged on the side wall of the outer drum 8, The inner drum 7 is fixedly installed on the main shaft assembly 9 that passes through the outer drum 8 and enters the inner cavity of the outer drum 8 , and the end of the main shaft assembly 9 located outside the outer drum 8 is connected to the motor 11 through the transmission device 10 ; the transmission device 10 is driven by the motor 11 to run , the transmission device 10 drives the inner drum 7 to rotate thereupon.

[0041] In this embodiment, the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com