Cross-linked polymer-based all-solid-state electrolyte material and application of cross-linked polyoxyethylene ether

A technology of cross-linked polymer and electrolyte material, applied in the field of lithium battery materials, can solve the problems of inability to work above 60 ℃, poor battery safety performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Using 71.00 parts of cross-linked polymer with a polyoxyethylene chain average molecular weight of 650 on the structural unit as the polymer matrix, 18.50 parts of LiTFSI as lithium salt, and 10.50 parts of polyvinylidene fluoride as a modifier to prepare an electrolyte membrane, and the electrolyte Membrane assembly into LiFePO 4 / electrolyte / Li half-cell. The conductivity of the electrolyte membrane at room temperature is 3.0×10 -5 S / cm, the electrochemical window is 5.20V. Its LiFePO 4 The charge-discharge specific capacity of the half-battery can reach 87mAh / g at 0.3C at room temperature, and the capacity remains basically unchanged after 100 cycles.

Embodiment 2

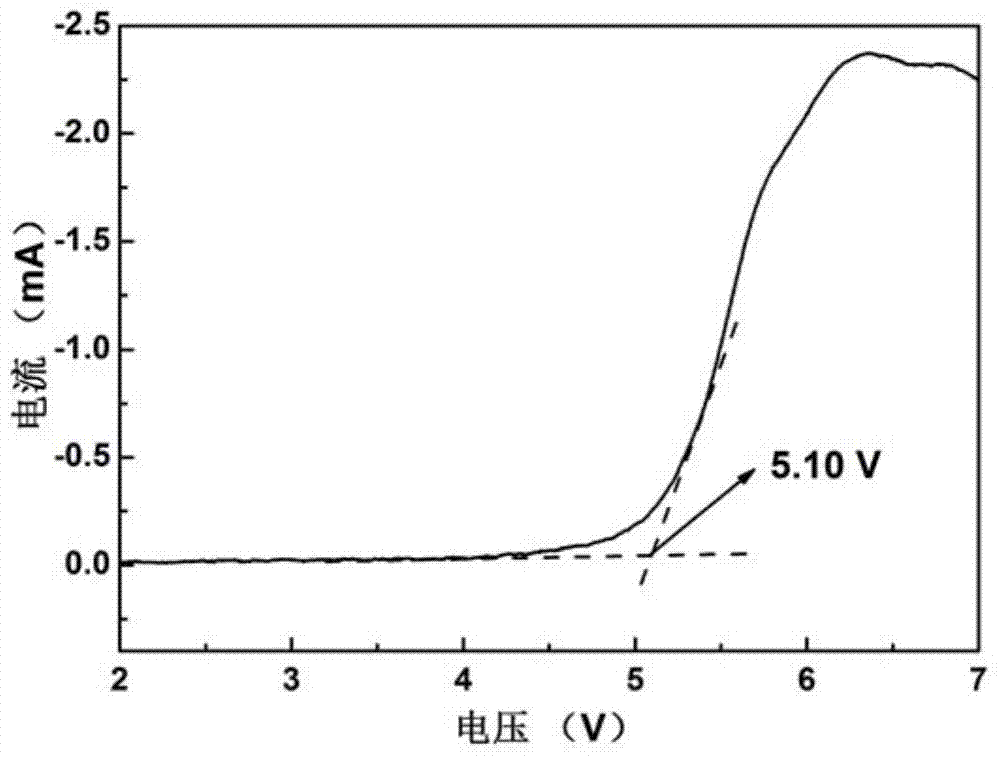

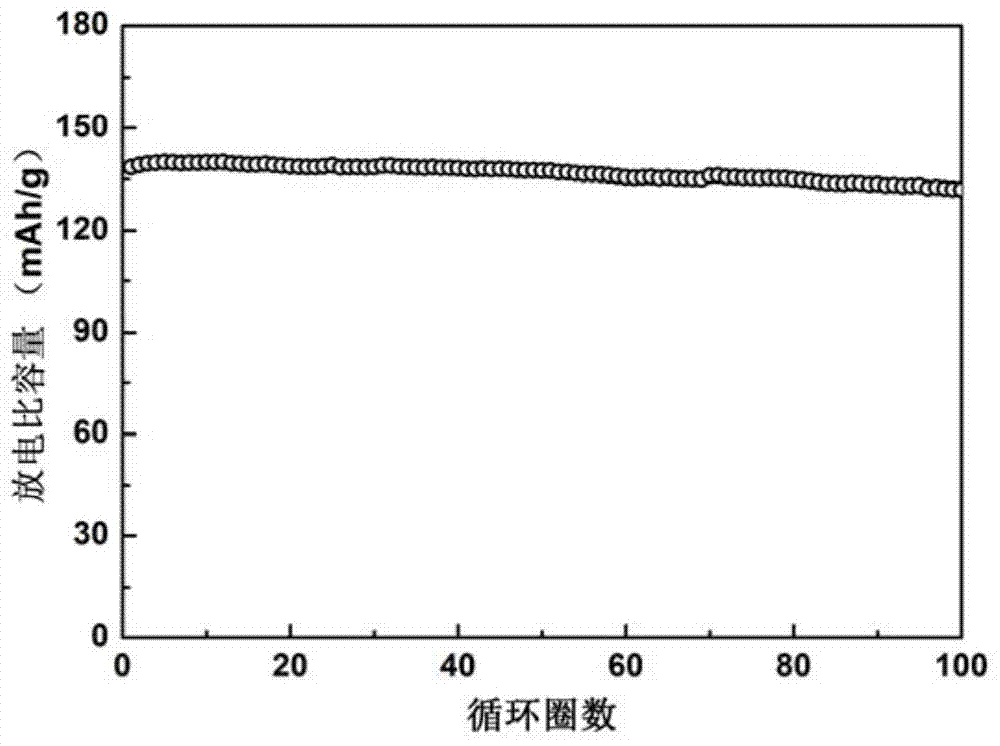

[0040] Prepare the same polymer electrolyte membrane as in Example 1 and assemble it into LiFePO 4 / electrolyte / Li half-cell. The conductivity of the electrolyte membrane at 60°C is 2.4×10 -4 S / cm, the electrochemical window is 5.10V. LiFePO assembled using this electrolyte membrane 4 The initial charge-discharge specific capacity of the half-cell at 60°C at 0.5C can reach 140mAh / g, and after 100 cycles it is 132mAh / g, with a capacity retention rate of 94%. Electrolyte electrochemical window and battery cycle test results are attached figure 1 And attached figure 2 Shown: from figure 1 It can be seen that the electrochemical window of the electrolyte described in Example 2 at 60°C can reach 5.10V, that is, no decomposition will occur at a potential lower than 5.10V; figure 2 It can be seen that the battery prepared by using the electrolyte in Example 2 has good cycle performance at 60°C, and after 100 cycles, the capacity retention rate reaches more than 90%.

Embodiment 3

[0042] Prepare the same polymer electrolyte membrane as in Example 1 and assemble it into LiFePO 4 / electrolyte / Li half-cell. The conductivity of the electrolyte membrane at 80°C is 5.3×10 -4 S / cm, the electrochemical window is 5.03V. LiFePO assembled using this electrolyte membrane 4 The charge-discharge specific capacity of the half-battery can reach 150mAh / g at room temperature at 0.5C, and it can reach 138mAh / g after 100 cycles, with a capacity retention rate of 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com