Mixed matrix type cation exchange membrane and preparation method thereof

A technology of cation exchange membrane and mixed matrix, which is applied in the field of mixed matrix cation membrane and its preparation, can solve the problems of poor ion selectivity, tensile resistance and swelling resistance, and achieves inhibition of water absorption and swelling and good tensile properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

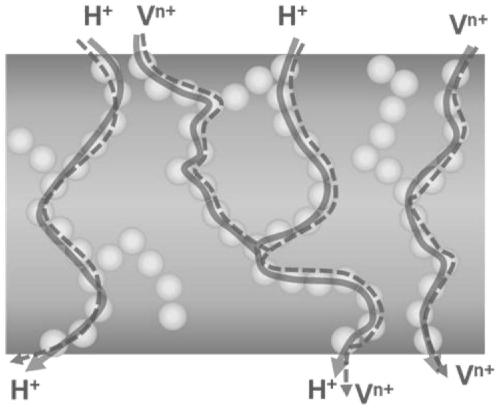

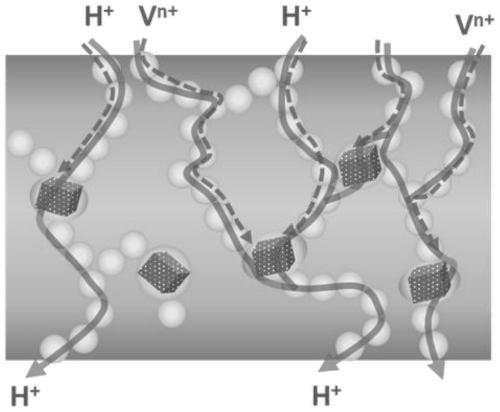

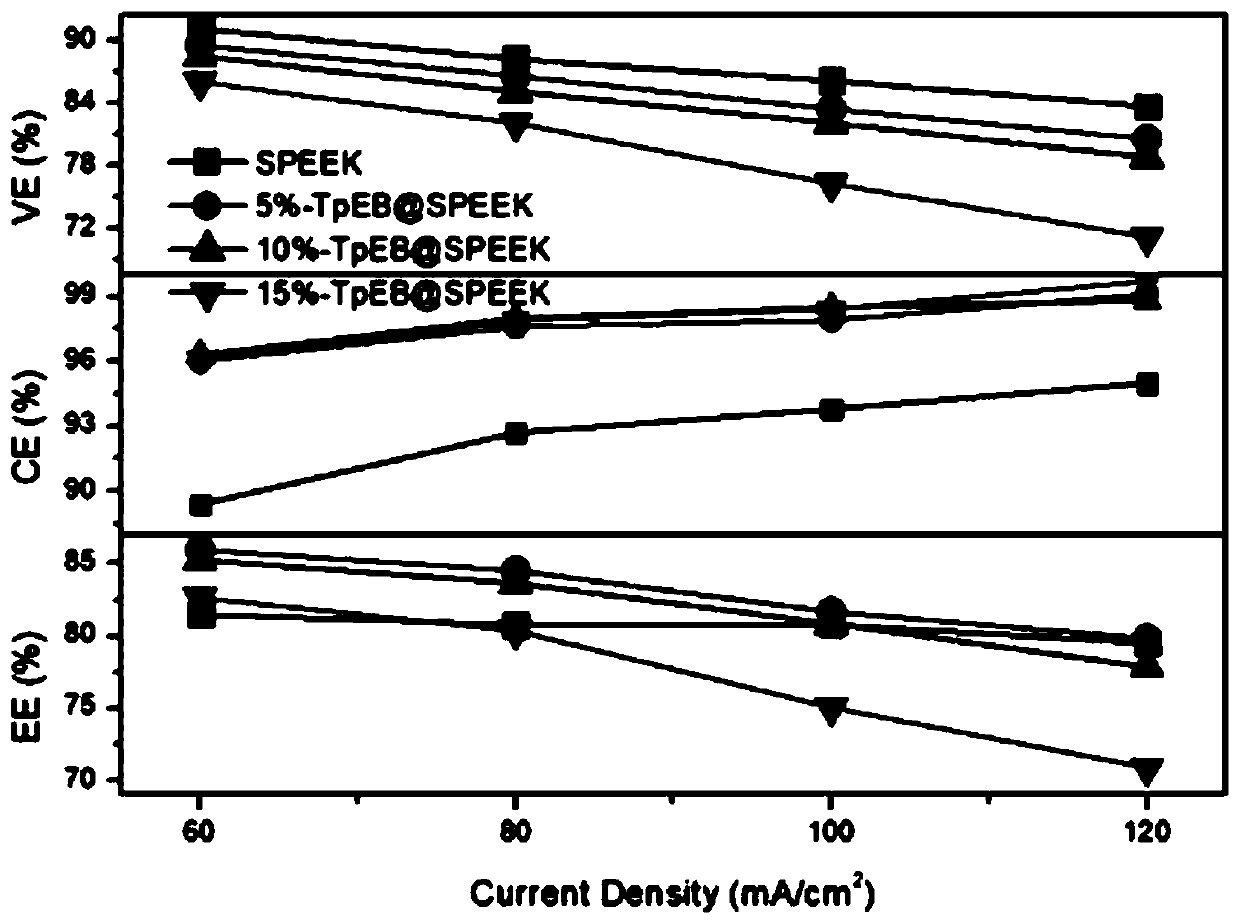

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Synthesis of 1,3,5-trialdehyde phloroglucinol: under nitrogen atmosphere, add 6.014g phloroglucinol, 15.098g urotropine and 90mL trifluoroacetic acid, react at 100°C for 2h, add 150mL 3mol / L hydrochloric acid aqueous solution, continue to react for 0.5h. After it was cooled to room temperature, it was filtered with diatomaceous earth, and the filtrate was extracted with 350 mL of dichloromethane. The organic phase was dried over anhydrous magnesium sulfate and rotary evaporated to obtain a yellowish powder, which was rinsed with an appropriate amount of hot ethanol and dried.

[0053] Synthesis of TpEB covalent organic framework material: weigh 63mg 1,3,5-trialdehyde phloroglucinol (Tp) and 177.5mg ethidium bromide (EB) in a ball mill jar, add 1 drop of mesitylene / The mixed solution of dioxane (volume ratio is 1:1) and 1 drop of 3mol / L hydrochloric acid solution are used as a catalyst, poured into some ball milling beads, and after grinding at a constant speed for 90 m...

Embodiment 2

[0057] Synthesis of 1,3,5-trialdehyde phloroglucinol: under nitrogen atmosphere, add 6.014g phloroglucinol, 15.098g urotropine and 90mL trifluoroacetic acid, react at 80°C for 2.5h, add 150mL of 3mol / L hydrochloric acid aqueous solution, continue to react for 1h. After it was cooled to room temperature, it was filtered with diatomaceous earth, and the filtrate was extracted with 350 mL of dichloromethane. The organic phase was dried over anhydrous magnesium sulfate and rotary evaporated to obtain a yellowish powder, which was rinsed with an appropriate amount of hot ethanol and dried.

[0058] TpBD-Me 2 Synthesis of covalent organic framework materials: Weigh 63mg 1,3,5-trialdehyde phloroglucinol (Tp) and 95.6mg bi-o-toluidine (BD-Me 2 ) in the ball mill tank, add 1 drop of mesitylene / dioxane (1:1 volume ratio) mixed solution to aid grinding, pour some ball mill beads, and grind at a uniform speed for 90 minutes, collect the resulting solids and use Soxhlet extraction with m...

Embodiment 3

[0061] Synthesis of 1,3,5-trialdehyde phloroglucinol: under nitrogen atmosphere, add 6.014g phloroglucinol, 15.098g urotropine and 90mL trifluoroacetic acid, react at 120°C for 2.25h, add 150mL of 3mol / L hydrochloric acid aqueous solution, continue to react for 0.75h. After it was cooled to room temperature, it was filtered with diatomaceous earth, and the filtrate was extracted with 350 mL of dichloromethane. The organic phase was dried over anhydrous magnesium sulfate and rotary evaporated to obtain a yellowish powder, which was rinsed with an appropriate amount of hot ethanol and dried.

[0062] TpBD-(OH) 2 Synthesis of covalent organic framework materials: Weigh 63mg 1,3,5-trialdehyde phloroglucinol (Tp) and 90.6mg 2,4-dihydroxybenzidine (BD-OH 2 ) in the ball mill tank, add 1 drop of mesitylene / dioxane (volume ratio: 1:1) mixed solution for grinding aid and 1 drop of 3mol / L hydrochloric acid solution as catalyst, pour some ball mill beads, and grind at a uniform speed fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com